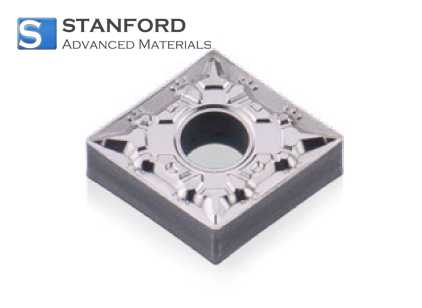

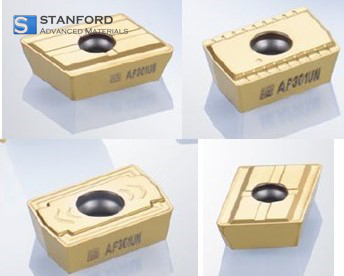

Uncoated Turning Insert for Non-ferrous Material AW100K Description

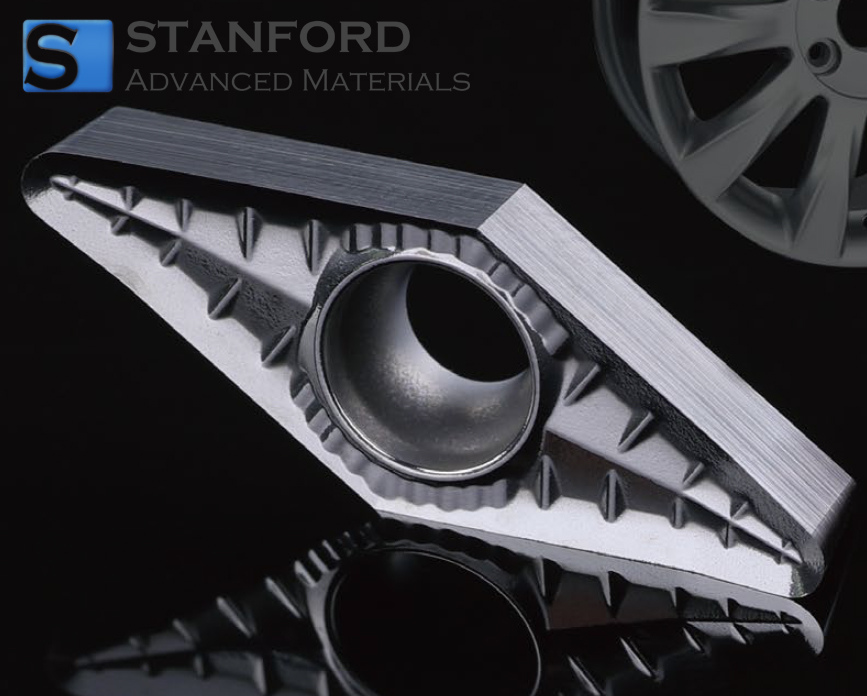

Uncoated Turning Insert for Non-ferrous Material AW100K is a new uncoated carbide grade with a new chip breaker geometry. The new chip breaker which is called NC2 is a positive insert that is optimized chip breaker design for non-ferrous material. Especially it has a high positive rake angle applies minimized built-up edge in machining on aluminum material and it can be efficiently realized smooth cutting and low machining power. In addition, the top surface of the insert is polished which can be increased longer tool life as well as less built-up edge. Inserts cutting edge has very sharp and it very suitable for small depth of cut and stable when high surface finish quality is required. In case of new grade, it has developed to uncoated carbide grade which is called AW100K. It has high hardness and excellent wear resistance including toughness. AW100K grade is the best solution for aluminum material.

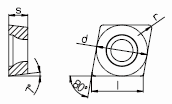

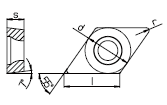

Uncoated Turning Insert for Non-ferrous Material AW100K Specifications

Recommended cutting speed by materials

|

Material

|

Silicon contents

|

Cutting Speed (Vc: m/min)

|

|

Aluminum and aluminum alloys

|

<6%

|

200-950

|

|

Aluminum + Silicon

|

>6%

|

100-500

|

Stock Items

|

Designation

|

Recommended parameter

|

Dimension(mm)

|

Geometry

|

|

Feed

|

ap

|

d

|

l

|

s

|

r

|

|

(mm/rev)

|

(mm)

|

(mm)

|

(mm)

|

(mm)

|

(mm)

|

|

CCGT 060204F-NC2

|

0.05-0.20

|

0.32-2.9

|

6.35

|

6.45

|

2.38

|

0.4

|

|

|

09T302F-NC2

|

0.02-0.10

|

0.16-4.4

|

9.525

|

9.67

|

3.97

|

0.2

|

|

09T304F-NC2

|

0.05-0.20

|

0.32-4.4

|

9.525

|

9.67

|

3.97

|

0.4

|

|

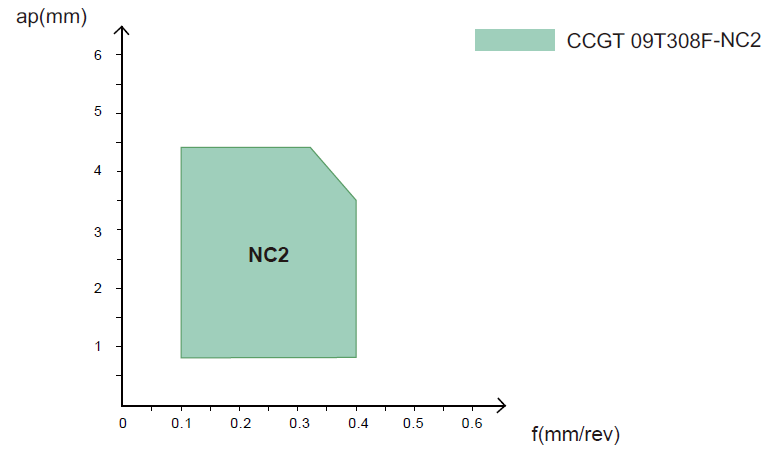

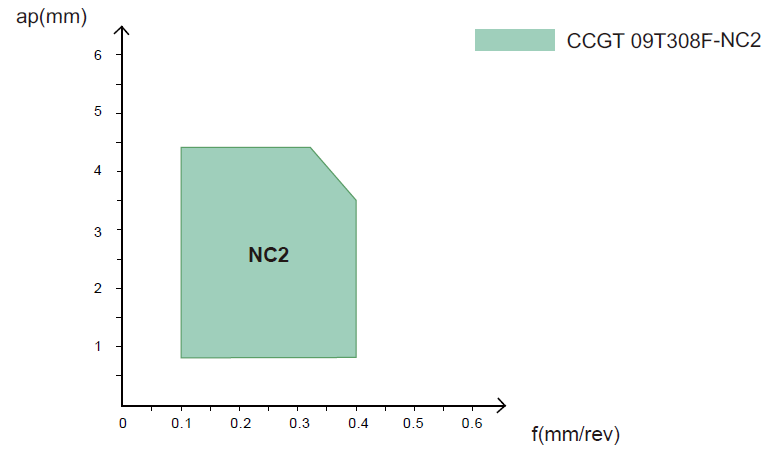

09T308F-NC2

|

0.10-0.40

|

0.64-4.4

|

9.525

|

9.67

|

3.97

|

0.8

|

|

120404F-NC2

|

0.05-0.20

|

0.32-5.8

|

12.7

|

12.9

|

4.76

|

0.4

|

|

120408F-NC2

|

0.10-0.40

|

0.64-5.8

|

12.7

|

12.9

|

4.76

|

0.8

|

|

DCGT 070202F-NC2

|

0.02-0.10

|

0.16-3.5

|

6.35

|

7.75

|

2.38

|

0.2

|

|

|

070204F-NC2

|

0.05-0.20

|

0.32-3.5

|

6.35

|

7.75

|

2.38

|

0.4

|

|

11T302F-NC2

|

0.02-0.10

|

0.16-5.2

|

9.525

|

11.62

|

3.97

|

0.2

|

|

11T304F-NC2

|

0.05-0.20

|

0.32-5.2

|

9.525

|

11.62

|

3.97

|

0.4

|

|

11T308F-NC2

|

0.10-0.40

|

0.64-5.2

|

9.525

|

11.62

|

3.97

|

0.8

|

|

SCGT 09T308F-NC2

|

0.10-0.40

|

0.64-4.3

|

9.525

|

9.525

|

3.97

|

0.8

|

|

|

TCGT 110204F-NC2

|

0.05-0.20

|

0.32-5.0

|

6.35

|

11

|

2.38

|

0.4

|

|

|

16T304F-NC2

|

0.05-0.20

|

0.32-7.4

|

9.525

|

16.5

|

3.97

|

0.4

|

|

16T308F-NC2

|

0.10-0.40

|

0.64-7.4

|

9.525

|

16.5

|

3.97

|

0.8

|

|

VCGT 110302F-NC2

|

0.02-0.10

|

0.16-2.8

|

6.35

|

11.07

|

3.18

|

0.2

|

|

|

110304F-NC2

|

0.05-0.20

|

0.32-2.8

|

6.35

|

11.07

|

3.18

|

0.4

|

|

160404F-NC2

|

0.05-0.20

|

0.32-4.2

|

9.525

|

16.61

|

4.76

|

0.4

|

|

160408F-NC2

|

0.10-0.40

|

0.64-4.2

|

9.525

|

16.61

|

4.76

|

0.8

|

|

160412F-NC2

|

0.14-0.60

|

0.96-4.2

|

9.525

|

16.61

|

4.76

|

1.2

|

|

220530F-NC2

|

0.36-1.50

|

2.40-5.5

|

12.7

|

22.1

|

5.56

|

3

|

|

RCGT 0803MOF-NC2

|

0.10-1.00

|

0.70-3.3

|

8

|

-

|

3.18

|

4

|

|

|

1003MOF-NC2

|

0.20-1.30

|

0.90-4.0

|

10

|

-

|

3.18

|

5

|

|

10T3MOF-NC2

|

0.20-1.30

|

0.90-4.0

|

10

|

-

|

3.97

|

5

|

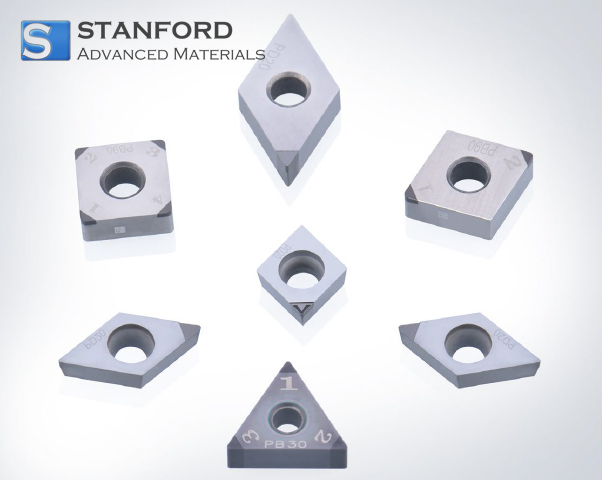

Uncoated Turning Insert for Non-ferrous Material AW100K Applications

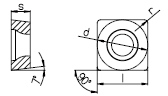

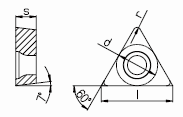

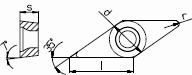

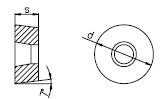

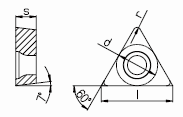

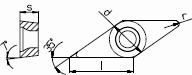

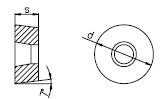

Chip breaker diagram

- Optimized chip breaker design for excellent chip controlling

- Very sharp positive rake angle

- Inclined cutting edge applies very smooth cutting and low cutting force

- Polished surface can be minimized built up edge and better surface finish

- Positive insert

- For finishing to semi-finishing

- First choice for aluminum machining

Uncoated Turning Insert for Non-ferrous Material AW100K Packaging

Our Uncoated Turning Insert for Non-ferrous Material AW100K is carefully handled during storage and transportation to preserve the quality of our product in its original condition.