1500C Compact Hydrogen Gas Tube Furnace GSL-1500X-50HG Description

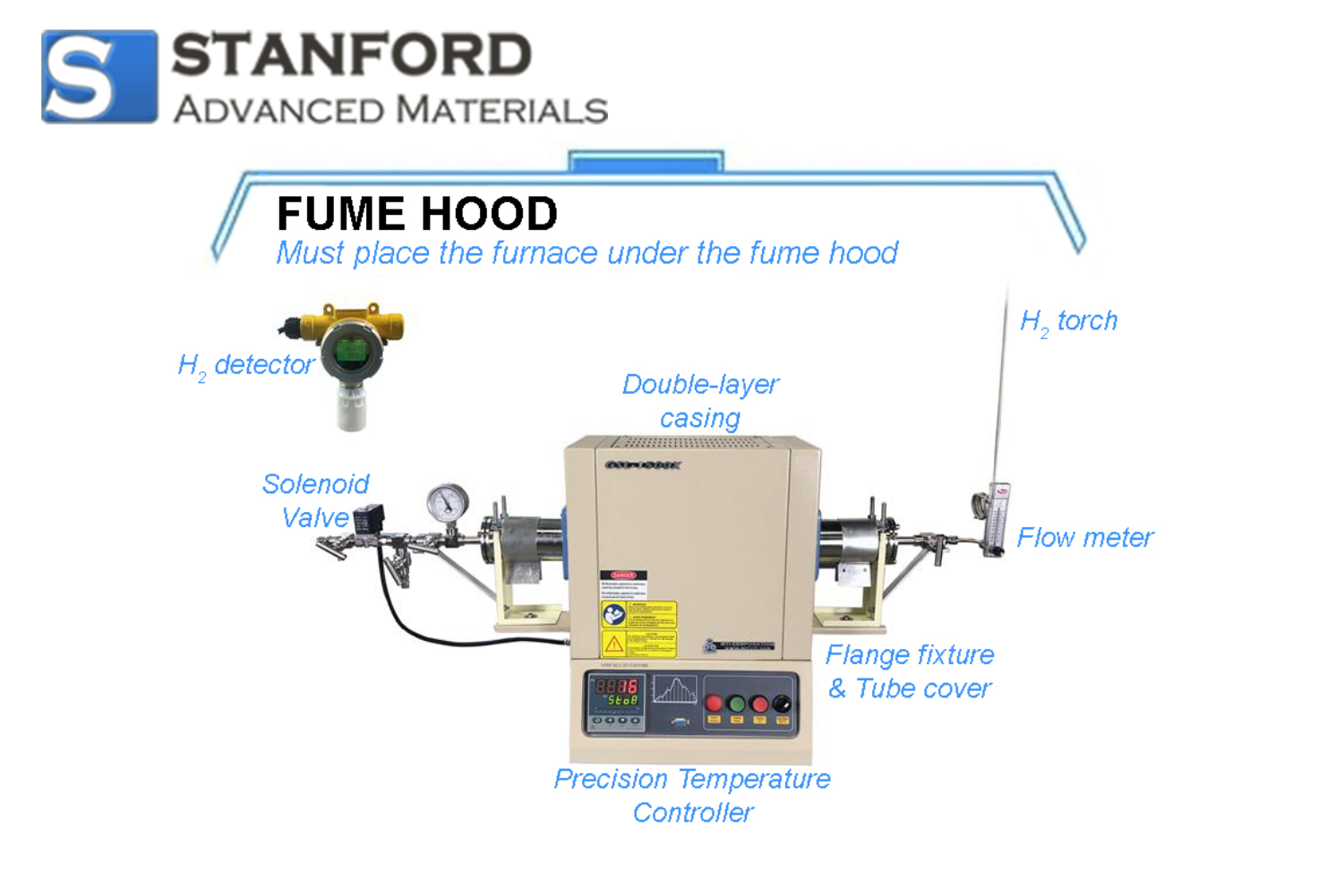

1500C Compact Hydrogen Gas Tube Furnace GSL-1500X-50HG is a compact hydrogen tube furnace designed for the heat treatment of oxidation-sensitive materials at temperatures up to 1500 ℃. Its 50 mm OD processing tube is constructed from pure alumina. To enhance safety measures, a Honeywell hydrogen leak detector and a solenoid valve are incorporated to shut off the hydrogen source and heating elements in the event of an H2 leak. Additional safety features include flange fixtures, quartz tube covers, and a double-layer steel furnace casing to protect in emergencies. The furnace is versatile, accommodating various inert gases as well as oxygen. With a precision temperature controller, users can establish their programmable heating profiles with up to 30 temperature segments.

1500C Compact Hydrogen Gas Tube Furnace GSL-1500X-50HG Specifications

|

Furnace Structure

|

- Double-layer steel casing with air cooling to keep furnace surface temperature lower than 60℃.

- High-purity fibrous alumina insulation for Max. energy saving.

- A hydrogen detector and solenoid valve are included for safe operation.

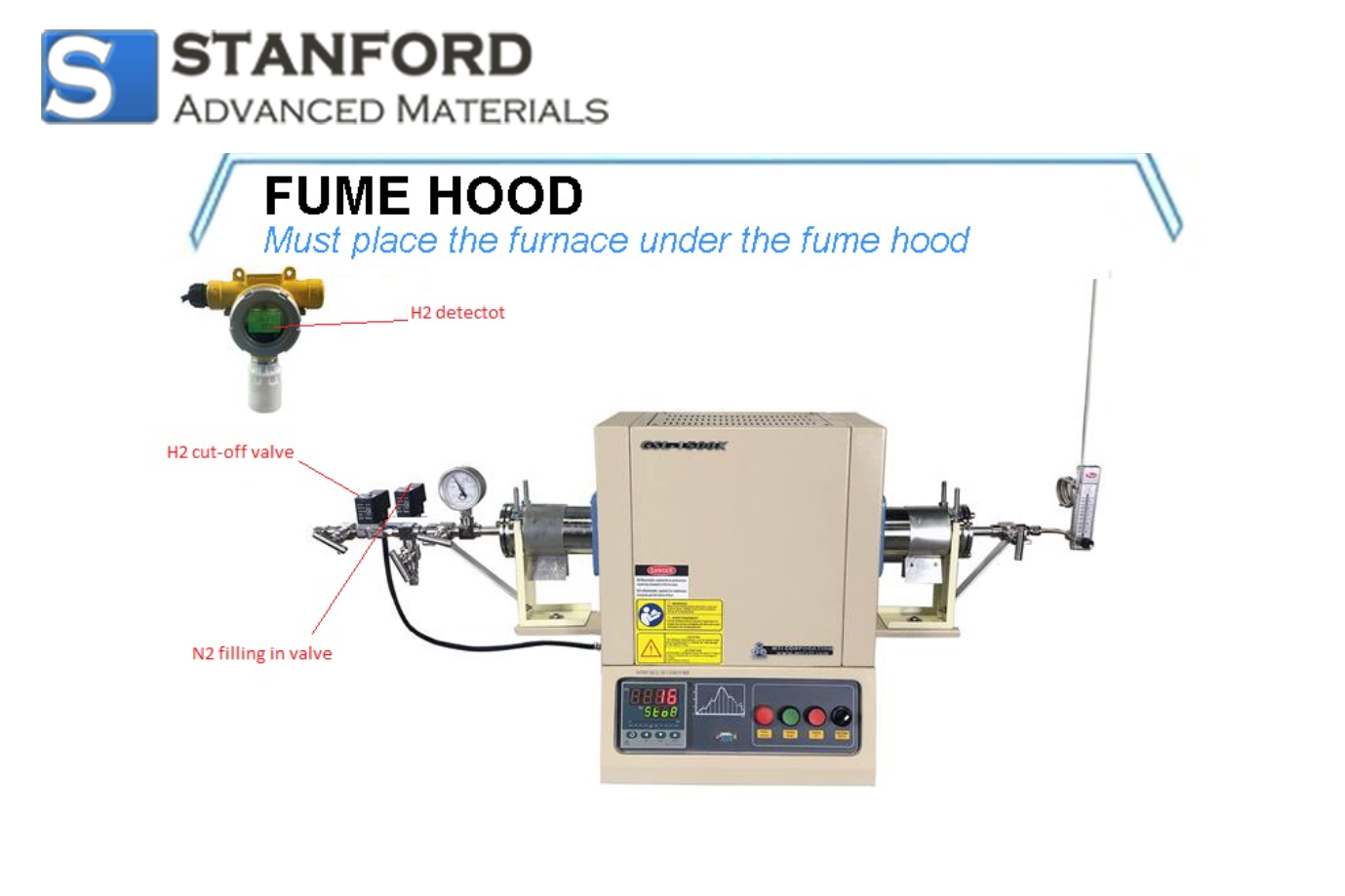

- The hydrogen gas furnace must be placed under a fume hood which is not included.

|

|

Power

|

- 2.5 KW Max. (20A breaker required)

- AC 208-240 Single Phase, 50/60 Hz

|

|

Working Temperature

|

- 1400 ℃ continuous operation

- 1500 ℃ (< 1 hour)

|

|

Max. Heating Rate

|

|

|

Processing Tube

|

- Material: High purity Alumina Tube

- Tube Size: 50 O.D x 38 I.D. x 700 Length. (mm)

- Two fibrous ceramic tube blocks are included to block heat radiation from the inside tube. (Ceramic blocks must be fully inserted into the furnace chamber before heating)

|

|

Heating Zone and Temperature Uniformity

|

- 6" (152 mm)

- 60 mm (± 2 ℃) heating area with the best temperature uniformity.

|

|

Temperature controller

|

- PID automatic control via SCR (Silicon Controlled Rectifier) power control.

- Self-tuning and built-in protection from the overheated and broken thermocouple. Please click here to learn why SCR is more accurate than SSR (Solid State Relay)

- MET certified 30 programmable segments for precise control of heating rate, cooling rate, and dwell time.

- Over-temperature protection and alarm allow for operation without attendant(s).

- +/- 1 ℃ temperature control during the dwelling.

- RS485 Communications Port.

- Computer-access Temperature Control (Optional)

- MTS02-Y Temperature control software kit (for YD518P series controllers) + 15" laptop package is available at the options bar.

- You may upgrade the temperature controller to the Eurotherm 3004 Temperature Controller which is compatible with LabVIEW. This package includes a Eurotherm 3004 programmer, and a communication cable (RS485 - USB). (Optional - LabVIEW program and OPC service are not included)

|

|

Temperature Control

|

- +/ - 1℃ during the dwelling.

|

|

Flanges and Gas Inlet

|

- One pair of stainless-steel vacuum flange is pre-connected for the two ends of the tube, which allows high vacuum up to 10E-5 torr and 5 PSI positive pressure.

- Two solenoid valves are installed on the left of the flange for the Hydrogen gas and N2 gas inlet. It connects with a hydrogen detector. Once a hydrogen gas leak is detected (20% lower explosive limit (LEL)), the H2 gas inlet valve will be closed and N2 gas valve will be opened, and heating elements will be shut down immediately

- One pressure gauge and a needle valve are installed to control the Hydrogen gas pressure, which must be less than 0.03 MPa.

|

|

Hydrogen Detector System

|

- One Honeywell UL Approved Sense Point Gas Detector is Integrated into the system.

- Working Temperature Range: 40ºF to +149ºF (-40℃ to +65℃)

- Alarm Point: H2 Limited Explosive Line 20% (20% LEL). Once detecting H2 gas beyond the point, it will shut off the inlet valve to the H2 and heating elements automatically.

|

|

Gas-outlet Flowmeter

|

- One 0 -1000 ml/min floating meter is installed on the gas-outlet end to adjust the gas flow rate.

- 1/4" Dia stainless steel tube is installed for burning hydrogen gas during gas flow.

- One long lighter is included in the standard package for igniting hydrogen gas manually.

- The solenoid valve automatically shuts down the gas inlet and heating elements in case of system failure.

|

|

Heating Element

|

- 1500 ℃ SiC Electric Heating Elements, 4 pcs.

|

|

Furnace Dimension

|

- 400 x 300 x 530 mm (15.7" x 12" x 21")

|

|

Net Weight

|

|

|

Shipping Weight

|

|

|

Shipping Dimension

|

|

|

Warranty

|

- One-year limited warranty for electrical and mechanical parts

|

|

Compliance

|

|

|

Warning

|

- The tube furnaces with alumina tubes are designed for use under vacuum and low pressure < 0.02 MPa / 0.2 Bar/ 3 PSI

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation.

- Never heat the furnace while the gas release valve is closed and a positive pressure shall be kept within the furnace chamber.

- The flow rate for gasses should be limited to < 200 SCCM (or 200ml/min)

- The hydrogen gas furnace must be placed under the fume hood.

- Vacuum limit definition for all alumina tube furnaces: * Vacuum pressures may only be safely used up to 1500℃

|

1500C Compact Hydrogen Gas Tube Furnace GSL-1500X-50HG Applications

1500C Compact Hydrogen Gas Tube Furnace GSL-1500X-50HG is used for sintering materials in inert or reducing gas environments.

1500C Compact Hydrogen Gas Tube Furnace GSL-1500X-50HG Packaging

Our 1500C Compact Hydrogen Gas Tube Furnace GSL-1500X-50HG is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

English

English Española

Española Deutsch

Deutsch Français

Français Italiano

Italiano