- Products

- Categories

- Blog

- Podcast

- Application

- Document

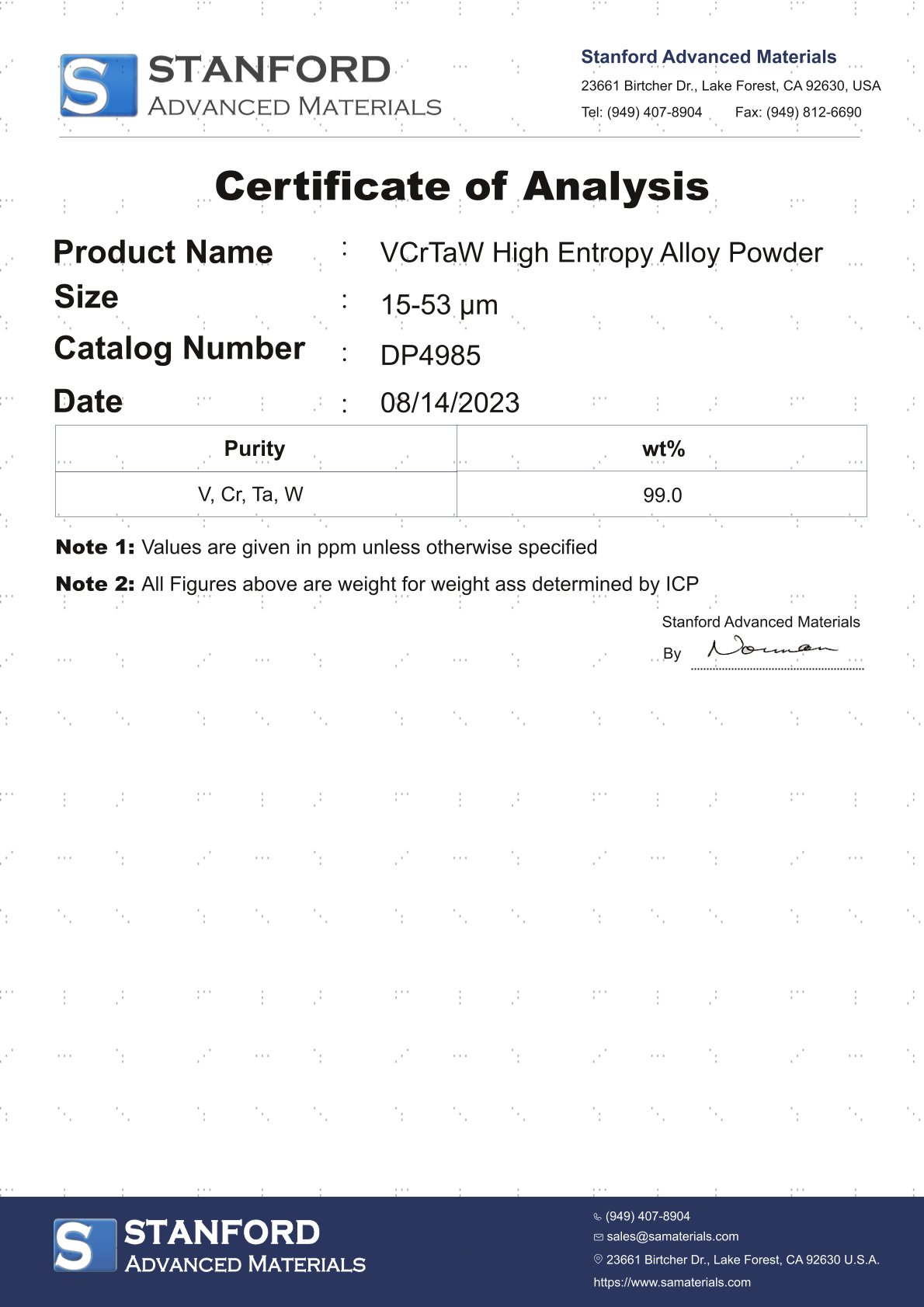

DP4985 VCrTaW High Entropy Alloy Powder

| Catalog No. | DP4985 |

| Compositions | V, Cr, Ta, W |

| Purity | 99% |

| Appearance | Gray or black powder |

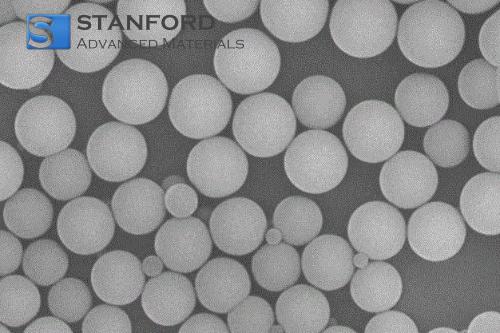

| Particle Size | 0-25um, 15-53um, 53-150um, or Custom Made |

VCrTaW High Entropy Alloy (HEA) Powder is a fine and homogeneous high-temperature powder material composed of an equimolar or near equimolar combination of vanadium (V), chromium (Cr), tantalum (Ta), and tungsten (W). Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality VCrTaW High Entropy Alloy Powder.

Related products: TiVZrNb, TiVCrZrNb, AlTiVNb, TiCrZrNb, AlCrFeNi

LATEST RECOMMENDED

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!