- Products

- Categories

- Blog

- Podcast

- Application

- Document

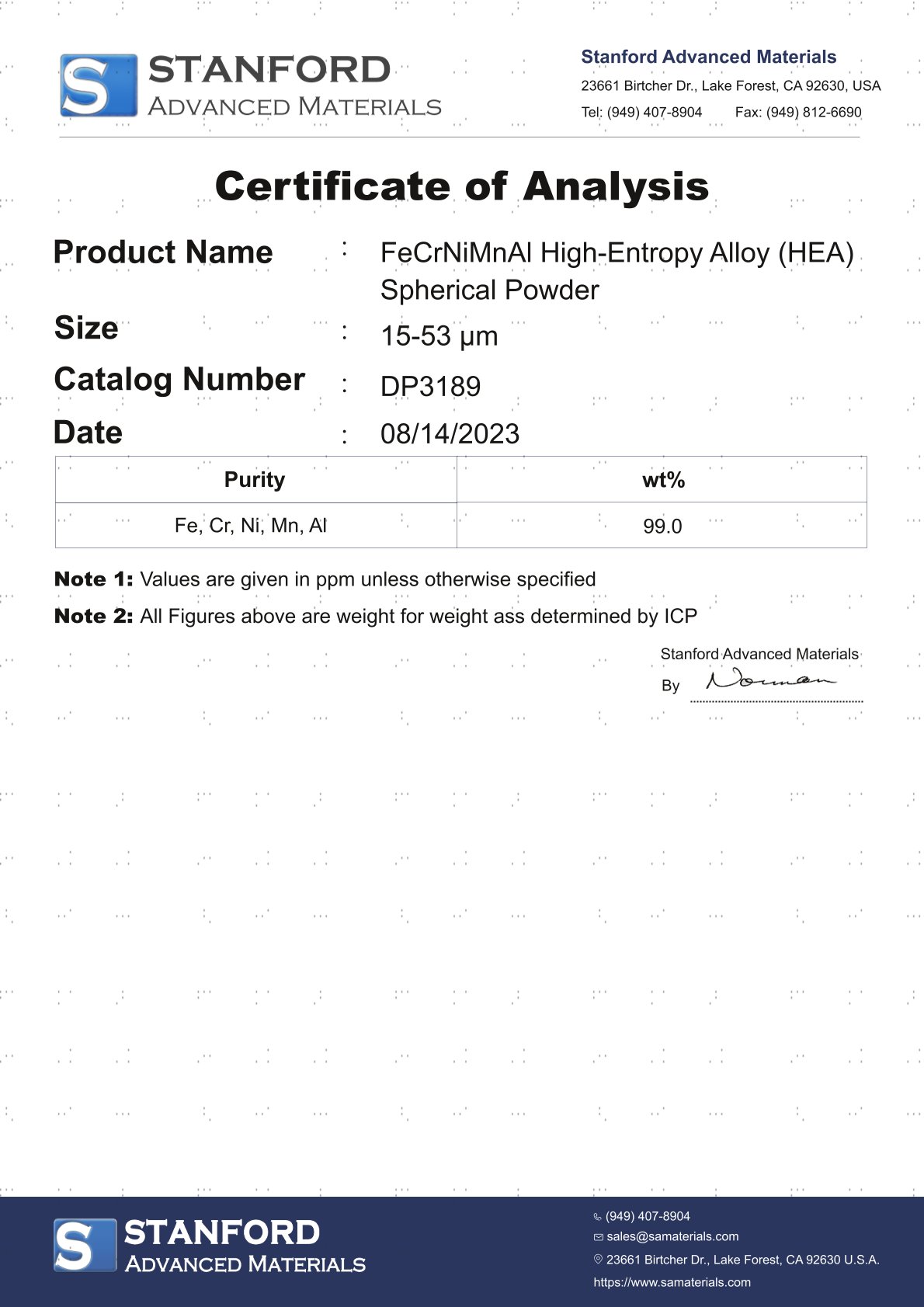

DP3189 FeCrNiMnAl High-Entropy Alloy (HEA) Spherical Powder

| Catalog No. | DP3189 |

| Material | Fe, Cr, Ni, Mn, Al |

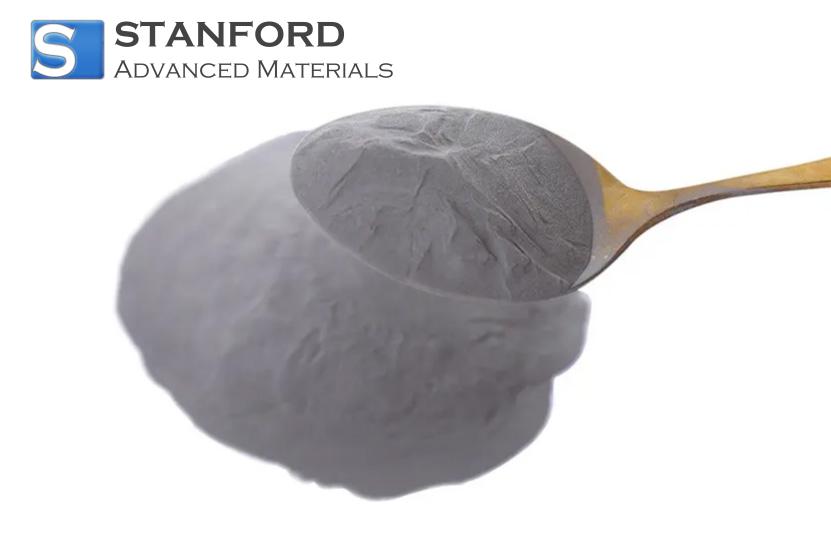

| Shape | Spherical Powder |

| Particle Size | 1. 0-45um, 0-53um, 15-45um, 15-53um, 45-105um |

FeCrNiMnAl High-Entropy Alloy (HEA) Spherical Powder can be bought at Stanford Advanced Materials (SAM). We are mainly engaged in the research and development, production and sales of high entropy alloy spherical powders, and provide high-quality metal powders personalized customized services.

Related products: FeMnCoCr High-Entropy Alloy (HEA) Spherical Powder, FeCoNiCrMo High-Entropy Alloy (HEA) Spherical Powder, FeCoNiCrMn High-Entropy Alloy (HEA) Spherical Powder, etc.

LATEST RECOMMENDED

Powder.jpg)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

.jpg)

.jpg)

Spherical Powder.jpg)

Spherical Powder - 2.jpg)