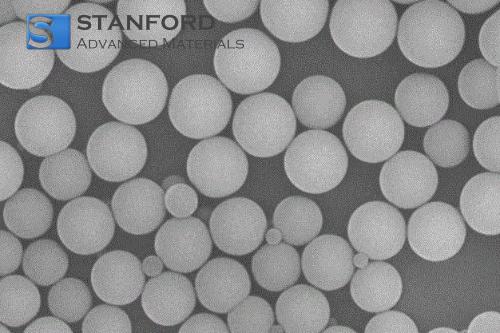

TiVNbMoTaW High Entropy Alloy Powder Description

TiVNbMoTaW High Entropy Alloy Powder is a complex refractory powder material with high strength, good ductility, thermal stability, and corrosion resistance. It has 4 refractory elements: Nb, Mo, Ta, and W, which improve the highest working temperature to even 1600℃. Refractory metals are easily oxidized when contacting O2 at high temperatures. Adding Ti can protect this HEA deeply oxidized in the air by forming a TiO2 surface layer.

TiVNbMoTaW High Entropy Alloy Powder Specifications

Chemical Composition

|

Element

|

Ti

|

V

|

Nb

|

Mo

|

Ta

|

W

|

|

Content (%)

|

16~17

|

16~17

|

16~17

|

16~17

|

16~17

|

16~17

|

Physical Properties

|

Particle size

|

0-25um, 15-53um, 53-150um, or Custom Made

|

|

Density

|

8.5~11 g/cm³

|

|

Melting point

|

>2000 ℃

|

|

Working Temperature

|

1200~1600 ℃

|

TiVNbMoTaW High Entropy Alloy Powder Applications

- Aerospace: The alloy features high strength, corrosion resistance, and lightweight properties, so it is suitable for aerospace components such as turbine blades, structural parts, and engine components.

- Energy: The alloy has excellent thermal stability, high-temperature strength, and corrosion resistance for energy generation and storage applications, such as turbine components and heat exchangers.

- Automotive: TiVNbMoTaW alloy can be utilized in automotive applications, including engine parts, exhaust systems, and components requiring high-temperature strength and wear resistance.

- High-Temperature Applications: The alloy is used for high-temperature environments, such as heat exchangers, furnaces, and thermal processing equipment.

- Research and Development: TiVNbMoTaW alloy powder can be used as a starting material for further research and development, allowing customization and exploration of its properties for specific applications.

- Additive Manufacturing: TiVNbMoTaW is well-suited for additive manufacturing processes, allowing the production of complex and customized components with exceptional mechanical strength and dimensional accuracy. It is particularly useful in powder bed fusion (PBF) and binder jetting (BJ) techniques.

TiVNbMoTaW High Entropy Alloy Powder Packaging

Our TiVNbMoTaW High Entropy Alloy Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)