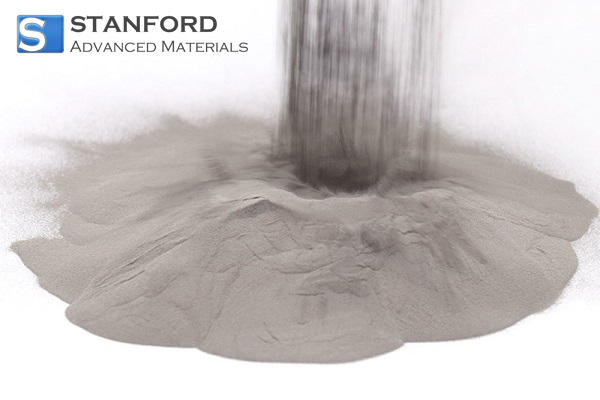

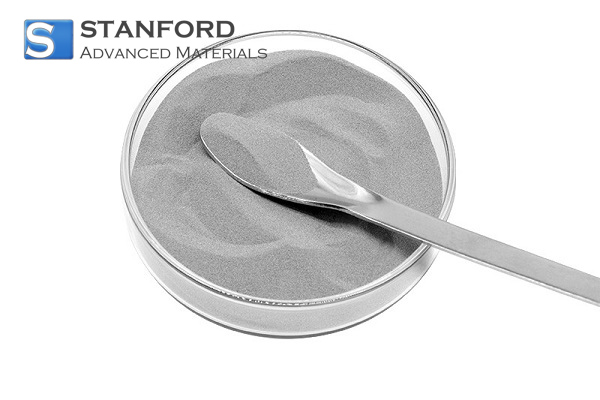

Titanium-Molybdenum Alloy Powder (Ti84Mo16) Description

Titanium-Molybdenum Alloy Powder (Ti84Mo16) is a finely engineered material that combines 84% titanium (Ti) and 16% molybdenum (Mo) in a homogeneous composition. Ti enhances the corrosion resistance, strength, toughness, and good biocompatibility of Titanium-Molybdenum Alloy. By combining with Mo which is one of the refractory metals, this alloy exhibits remarkable mechanical properties, excellent corrosion resistance, and impressive thermal stability.

Titanium-Molybdenum Alloy Powder (Ti84Mo16) Specifications

|

Chemical Formula

|

Ti84Mo16

|

|

Content

|

Ti 84%, Mo 16%

|

|

Particle Size

|

0~150μm or customized

|

|

Purity

|

99.9%

|

|

Morphology

|

Spherical

|

|

Melting Point (℃)

|

1900

|

Titanium-Molybdenum Alloy Powder (Ti84Mo16) Applications

- Aerospace and Aviation: The exceptional strength-to-weight ratio, corrosion resistance, and high-temperature stability of Ti-Mo alloy powder make it an ideal material for aerospace and aviation applications. It is employed in the production of aircraft components, engine parts, structural elements, and fasteners.

- Medical Devices: Ti-Mo alloy powder finds extensive use in the medical field due to its biocompatibility, strength, and corrosion resistance. It is utilized in the manufacturing of orthopedic implants, dental implants, surgical instruments, and other medical devices.

- Chemical Processing: The corrosion resistance of Ti-Mo alloy powder makes it suitable for chemical processing applications. It is utilized in the fabrication of reaction vessels, valves, pumps, and other components that come into contact with corrosive chemicals.

- Electronics and Electrical Components: Ti-Mo alloy powder's excellent electrical conductivity makes it suitable for electrical and electronic applications. It is utilized in the production of electrical contacts, connectors, high-power resistors, and electrodes for electrical discharge machining (EDM).

- High-Temperature Applications: Ti-Mo alloy powder's high-temperature stability and mechanical strength make it suitable for applications that involve elevated temperatures. It is used in the manufacturing of heat exchangers, furnace components, and other high-temperature equipment.

Titanium-Molybdenum Alloy Powder (Ti84Mo16) Packaging

Our Titanium-Molybdenum Alloy Powder (Ti84Mo16) is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

.jpg)