The Role of SOI in Automotive Systems

Introduction

In recent years, automotive technology has evolved dramatically, particularly with the rise of electric vehicles (EVs), autonomous driving, and Advanced Driver Assistance Systems (ADAS). As vehicles become increasingly sophisticated, there is a growing demand for semiconductor solutions that can handle complex, high-performance computing tasks while maintaining energy efficiency and reliability.

One of the most important innovations addressing this need is Silicon on Insulator (SOI) technology. SOI has proven to be a critical enabler in advancing the performance and reliability of semiconductor devices, particularly in automotive applications where safety, efficiency, and durability are paramount.

What is SOI Technology

SOI is a semiconductor manufacturing technique that places a thin layer of silicon on an insulating substrate, typically silicon dioxide (SiO2). This structure improves the electrical performance of transistors by reducing parasitic capacitance, which in turn enhances speed, reduces power consumption, and improves thermal efficiency. SOI-based devices are commonly used in various fields, including consumer electronics, telecommunications, and now, increasingly in automotive systems.

Related reading: Comparing SOI vs. Silicon Wafers: What’s Best for Your Semiconductor Project?

Why SOI is Important for Automotive Systems

Modern vehicles are packed with sensors, controllers, and communication systems that demand high computational power. These systems must operate reliably in harsh conditions, withstanding temperature extremes, vibrations, and electromagnetic interference. SOI technology offers several key advantages that make it ideal for automotive applications:

1. Low Power Consumption

One of the key advantages of SOI technology is its ability to operate at lower power levels. Power efficiency is crucial in automotive systems, especially for electric vehicles (EVs) and hybrid electric vehicles (HEVs), where conserving battery life is a priority. SOI devices reduce leakage current, which helps minimize energy loss and enhances overall efficiency. According to a study by GlobalFoundries, SOI-based chips consume up to 30% less power than conventional bulk silicon chips, making them ideal for power-sensitive applications such as ADAS and infotainment systems.

2. Improved Thermal Performance

Automotive environments can be extreme, with components often exposed to high temperatures. The insulating layer in SOI structures reduces heat transfer between the silicon substrate and other components, resulting in better thermal management.

STMicroelectronics has demonstrated that SOI devices can operate at temperatures as high as 200°C, making them particularly suitable for automotive powertrain control units and engine management systems. This improved thermal performance increases the lifespan and reliability of SOI-based chips, ensuring consistent performance over time.

3. Enhanced Performance for ADAS and Autonomous Driving

ADAS and autonomous driving systems rely on the rapid processing of large amounts of data from various sensors, cameras, and radar units. These systems demand high-speed processing and real-time data analysis to perform tasks like lane-keeping assistance, automatic emergency braking, and adaptive cruise control.

A recent study by Leti, a French research institute, found that SOI technology provides 30% faster processing speeds for ADAS systems compared to traditional silicon devices. SOI-based chips are not only faster but also more energy-efficient, making them ideal for integration into ADAS modules.

4. Superior Signal Integrity and Noise Immunity

Automotive environments are often noisy in terms of electromagnetic interference (EMI) due to various electronic systems operating simultaneously. SOI technology inherently provides superior signal integrity and reduces susceptibility to noise. The insulating layer in SOI substrates helps shield transistors from interference, improving the robustness of automotive electronic systems.

SOI in Key Automotive Applications

As the automotive sector embraces next-generation technologies, SOI is finding applications across various key systems.

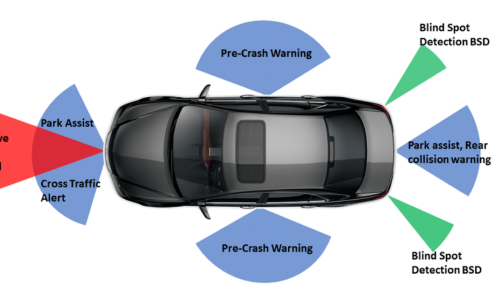

1. ADAS (Advanced Driver Assistance Systems)

ADAS features, such as adaptive cruise control, lane departure warning, blind-spot detection, and automatic emergency braking, rely on high-speed, low-power processing of sensor data. SOI technology is used in the processors and control units that support ADAS functions, providing the computational power needed to interpret sensor input in real time.

[1]

[1]

In 2020, the S32 microcontroller family for ADAS was introduced, which utilizes SOI technology to achieve a 50% reduction in power consumption while maintaining high processing power. This innovation enables automakers to integrate more advanced ADAS features without compromising energy efficiency.

2. Powertrain and Battery Management

SOI technology is increasingly being used in powertrain control units, which are responsible for optimizing engine performance, reducing emissions, and improving fuel efficiency. In electric vehicles (EVs), SOI-based chips can also be found in battery management systems (BMS), which monitor and control the charging and discharging of batteries.

For example, one of the best SOI-based battery management systems has been shown to improve battery life by 15% due to its energy-efficient operation and better thermal handling. These systems need to operate efficiently to prolong battery life and optimize energy usage, areas where SOI’s low-power capabilities shine.

3. Infotainment Systems

Modern infotainment systems offer features such as GPS navigation, multimedia playback, and wireless communication, all of which demand high processing power while maintaining power efficiency. SOI technology allows for the development of processors that can handle the complex tasks required by these systems without excessive heat generation or power consumption.

4. Vehicle-to-Everything (V2X) Communication

V2X communication allows vehicles to exchange information with other vehicles, infrastructure, and pedestrians. This communication is critical for the future of connected and autonomous vehicles, as it helps prevent accidents and ensures smoother traffic flow. SOI technology provides the performance and reliability needed for the processors that manage V2X communication, offering low latency and high data throughput.

SOI’s Impact on Automotive Safety and Reliability

Safety and reliability are critical concerns in the automotive industry, and SOI technology plays a pivotal role in addressing these challenges. The improved thermal performance and low power consumption of SOI devices reduce the risk of failure due to overheating or excessive power draw. Additionally, the enhanced noise immunity and signal integrity of SOI-based chips ensure that automotive systems can operate reliably even in the presence of strong electromagnetic interference.

In safety-critical applications like ADAS, reliability is paramount. A study found that SOI-based sensors in ADAS systems reduce system failures by 25%, making them a preferred choice for automakers focusing on safety. Malfunctions or failures in these systems can lead to accidents, so using semiconductor technologies that offer superior performance and stability, such as SOI, is essential.

The Future of SOI in Automotive Systems

As the automotive industry continues to evolve towards fully autonomous vehicles and more advanced electric vehicles, the demand for high-performance, energy-efficient semiconductor solutions will only grow. SOI technology, with its unique advantages in power efficiency, thermal management, and signal integrity, is well-positioned to meet these needs. Its applications will likely expand further, supporting not only ADAS but also advanced infotainment, V2X communication, and other emerging automotive technologies.

Conclusion

In a word, Silicon on Insulator (SOI) technology is proving to be a game-changer in the automotive sector, particularly in systems requiring high performance, low power consumption, and reliability under harsh conditions. As vehicles become smarter and more automated, SOI will continue to play a key role in driving innovation and ensuring the safety and efficiency of modern automotive systems. For more information about SOI, please check Stanford Advanced Materials (SAM).

Reference:

[1] Chipengo, Ushemadzoro. (2018). Full Physics Simulation Study of Guardrail Radar-Returns for 77 GHz Automotive Radar Systems. IEEE Access. PP. 1-1. 10.1109/ACCESS.2018.2881101.