- Products

- Categories

- Blog

- Podcast

- Application

- Document

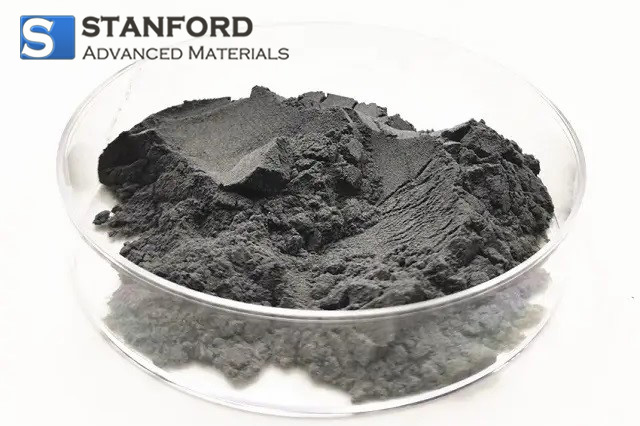

TS4600 Spherical Molybdenum Disilicide (MoSi2) Powder for thermal spraying

| Catalog No. | TS4600 |

| CAS Number | 12136-78-6 |

| Compositions | MoSi2 |

| Average Particle Size | 0.5-1.0um or customized |

| Appearance | gray powder |

Spherical Molybdenum Disilicide (MoSi2) for thermal spraying is a gray metallic color powder with electrical conductivity. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Spherical Molybdenum Disilicide (MoSi2) for thermal spraying.

Related products: Micro Molybdenum Disilicide (MoSi2), Special Shape Molybdenum Disilicide (MoSi2) Heating Elements, W-type Molybdenum Disilicide (MoSi2) Heating Rods

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!