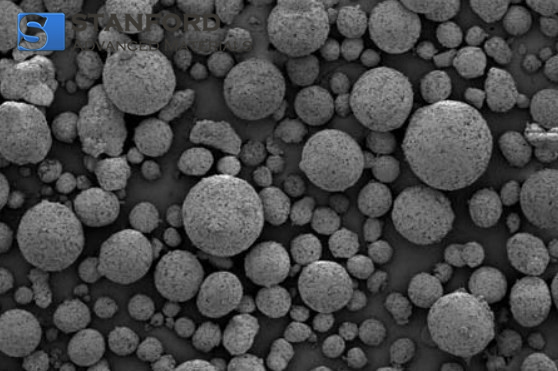

Spherical Aluminum Nitride Powder Description

Spherical Aluminum Nitride Powder is produced by a carbothermal reduction process using a highly active aluminum source and a carbon source. The thermal conductivity of AlN is ten times that of Al₂O₃, reaching 80~320W/m·k, not the same characteristic of anisotropy heat dissipation of BN. It features a high sphere formation rate, small specific surface area narrow particle size distribution, and high purity.

Therefore, Spherical Aluminum Nitride Powder is an important raw material for the preparation of AlN ceramic substrates and the production of various types of high thermal conductivity products.

Spherical Aluminum Nitride Powder Specifications

|

Technical Item

|

Unit

|

SSAN-F1

|

SSAN-F2

|

SSAN-C1

|

SSAN-Y1B

|

|

Particle Size

|

D10

|

μm

|

24.1

|

31.75

|

49.6

|

71.0

|

|

D50

|

38.3

|

50.75

|

74.7

|

107.5

|

|

D90

|

61.5

|

80.11

|

111.5

|

134.0

|

|

True Density

|

g/cm3

|

3.29

|

3.30

|

3.30

|

3.32

|

|

Specific Surface Area

|

m2/g

|

0.05

|

0.05

|

0.03

|

0.03

|

|

Tap Density

|

g/cm3

|

2.00

|

2.02

|

2.10

|

2.21

|

|

Moisture

|

%

|

0.08

|

0.07

|

0.06

|

0.02

|

|

Chemical Composition

|

O

|

%

|

1.20

|

1.20

|

1.32

|

1.24

|

|

C

|

ppm

|

126

|

120

|

119

|

119

|

|

Si

|

ppm

|

40

|

40

|

40

|

40

|

|

Fe

|

ppm

|

20

|

20

|

20

|

20

|

|

Na

|

ppm

|

15

|

15

|

15

|

15

|

Spherical Aluminum Nitride Powder Applications

Spherical Aluminum Nitride (AlN) Powder is highly valued across advanced industries for its unique properties and versatile applications. Primarily used in thermal management, it serves as a key component in thermal interface materials (TIMs), thermal pastes, and greases, improving heat dissipation in electronic devices and semiconductor encapsulation. In optoelectronics, enhances LED encapsulation materials, ensuring efficient heat management and extending device lifespan. The powder's role extends to ceramics and composites, where it reinforces materials, enhances thermal and mechanical properties, and supports additive manufacturing processes like powder bed fusion. Spherical AlN powder also finds applications in functional coatings, energy storage systems, catalyst supports, and environmental technologies such as water filtration, leveraging its thermal conductivity, electrical insulation, and chemical stability. Overall, spherical AlN powder plays a crucial role in advancing technology across electronics, optoelectronics, ceramics, energy, and environmental sectors, meeting diverse industrial needs for efficient thermal management and material performance.

Spherical Aluminum Nitride Powder Packaging

Our Spherical Aluminum Nitride Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Spherical Aluminum Nitride Powder FAQs

Q1: How is spherical aluminum nitride powder produced?

A: Spherical aluminum nitride powder is typically produced using methods like spray drying, plasma spraying, or chemical vapor deposition (CVD). These methods help achieve the desired spherical shape and high purity.

Q2: What particle sizes are available for spherical aluminum nitride powder?

A: Spherical aluminum nitride powder is available in various particle sizes, from nanometers to micrometers, to meet the specific needs of different applications.

Q3: What are the considerations for handling and storing spherical aluminum nitride powder?

A: Spherical aluminum nitride powder should be stored in a dry, cool environment to prevent moisture absorption. Proper protective equipment should be used to avoid inhalation and skin contact during handling.

.jpg)