- Products

- Categories

- Blog

- Podcast

- Application

- Document

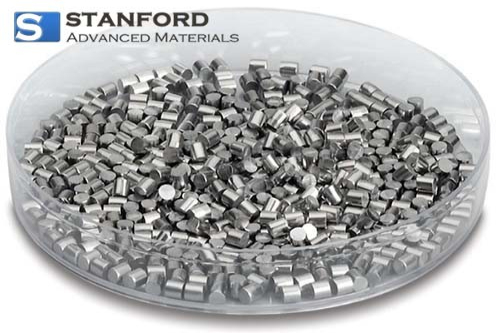

VD0545 Dysprosium (Dy) Evaporation Materials

| Catalog No. | VD0545 |

| Material | Dysprosium (Dy) |

| Purity | 99.5% ~ 99.9% |

| Shape | Powder/ Granule/ Custom-made |

| MSDS/SDS |

Dysprosium (Dy) Evaporation Materials refer to substances containing dysprosium that are used in the process of thin-film deposition through physical vapor deposition (PVD) techniques. Stanford Advanced Materials (SAM) boasts extensive experience in providing Dysprosium (Dy) Evaporation Materials with both high purity and competitive pricing.

Related products: Antimony (Sb) Evaporation Materials, Aluminum (Al) Evaporation Materials

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!