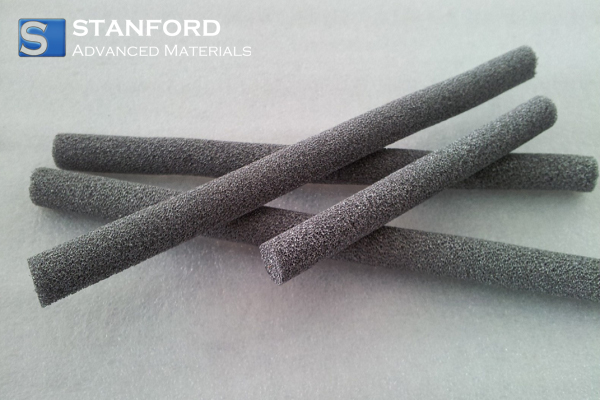

Nickel Molybdenum Foam (Ni-Mo Foam) Description

Nickel Molybdenum Foam (Ni-Mo Foam) is a porous 3-dimensional structure made of nickel-molybdenum alloy. Nickel-molybdenum alloys have high electrical conductivity and low resistivity, which makes Ni-Mo Foam one of the best electrode materials used in energy storage devices.

Nickel Molybdenum Foam (Ni-Mo Foam) Specifications

|

Purity

|

>99%

|

|

Width (mm)

|

100-960

|

|

Cell Size (PPI)

|

50~130

|

|

Porosity

|

≥95%

|

|

Thickness

|

1.0~4.0mm

|

|

Surface Density (g/m2)

|

200~600

|

Nickel Molybdenum Foam (Ni-Mo Foam) Applications

Nickel Molybdenum Foam (Ni-Mo Foam) is mainly used as an electrode material used in industrial water electrolysis for hydrogen production due to its porosity, long lifetime, and good electrochemical stability. Ni-Mo Foam is used as a catalyst support material, a heat exchanger, a structural material, or even a filter media in many industries such as aerospace, chemical processing, and energy storage.

Nickel Molybdenum Foam (Ni-Mo Foam) Packaging

Our Nickel Molybdenum Foam (Ni-Mo Foam) is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Nickel Molybdenum Foam (Ni-Mo Foam) FAQs

Q1. What is Nickel Molybdenum Foam?

Nickel Molybdenum Foam is a porous metallic material made from a combination of nickel (Ni) and molybdenum (Mo). The foam structure provides a high surface area while retaining good electrical conductivity and mechanical strength. It is typically used in energy storage, catalysis, filtration, and electrochemical applications.

Q2. How is Nickel Molybdenum Foam used in batteries?

Nickel Molybdenum Foam is used as a current collector in batteries, particularly in lithium-ion and sodium-ion batteries. Its high porosity increases the active surface area, improving the efficiency of electrochemical reactions, resulting in faster charging and better overall battery performance.

Q3. What advantages does Nickel Molybdenum Foam offer for catalysis?

- High Surface Area: The foam structure provides a large active surface for catalytic reactions.

- Corrosion Resistance: It remains stable in harsh chemical environments, especially in alkaline or acidic solutions, which is beneficial for catalytic processes.

- Hydrogen Evolution Reactions (HER): Nickel Molybdenum Foam is effective as a catalyst for HER in water splitting, helping generate hydrogen efficiently.