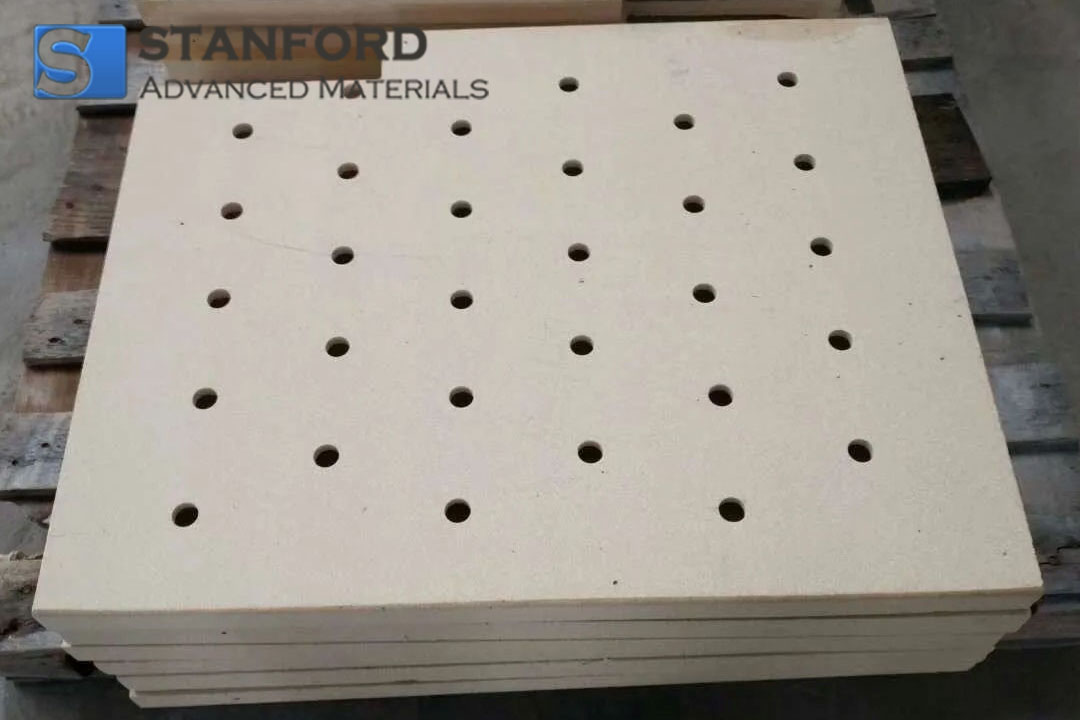

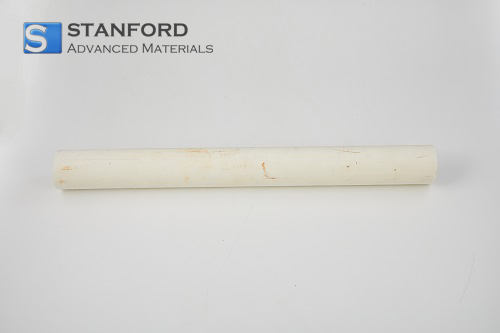

Nano Microporous Insulation Board Description

Nano Microporous Insulation Board is made of high-purity Silicate and Ti2Si2O5 particle powder together with binders. Based on special microporous technology, this insulating product has the best thermal conductivity, which is lower than that of stationary air under atmospheric pressure. Its insulating performance is 3-10 times better than traditional fiber insulation.

Nano Microporous Insulation Board Specifications

|

Chemical Composition

|

SiO2: 45%

Ti2Si2O5 + SiO2: 50%

|

SiO2: 50%

Ti2Si2O5 + SiO2: 45%

|

SiO2: 45%

Ti2Si2O5 + SiO2: 45%

|

|

Max. Working Temperature (℃)

|

1200

|

1000

|

900

|

|

Density (g/cm3)

|

220-350

|

220

|

220

|

|

Linder Shrinkage

|

<2%

|

Nano Microporous Insulation Board Applications

1. High-Temperature Furnaces and Kilns: Nano microporous insulation boards are used as lining materials in high-temperature furnaces, kilns, and other industrial heating equipment. Their low thermal conductivity minimizes heat loss, improving energy efficiency and maintaining consistent internal temperatures.

2. Aerospace and Aviation: In the aerospace industry, these insulation boards are used in thermal protection systems for spacecraft, aircraft, and satellites. They protect sensitive components from extreme temperatures during re-entry, flight, or in space environments.

3. Oil and Gas Industry: Nano microporous insulation boards are used in the oil and gas industry for insulating pipelines, storage tanks, and processing equipment. Their high thermal resistance helps maintain the desired temperature of fluids, gases, and other materials, preventing heat loss and ensuring process efficiency.

4. Industrial Equipment and Machinery: These boards are used to insulate industrial equipment and machinery that operates at high temperatures, such as boilers, heat exchangers, and reactors. The insulation helps protect surrounding components, reduce energy consumption, and maintain safe operating conditions.

5. Power Generation: In power plants, especially steam turbines and boilers, nano-microporous insulation boards are used to minimize heat loss and improve overall energy efficiency. They contribute to reducing fuel consumption and greenhouse gas emissions.

6. Automotive Industry: In the automotive sector, these insulation boards are used in exhaust systems, catalytic converters, and other high-temperature components to protect surrounding parts from heat damage and improve thermal management.

7. Cryogenic Applications: Nano microporous insulation boards are also used in cryogenic applications, such as in the storage and transport of liquefied gases (e.g., LNG, liquid hydrogen). Their low thermal conductivity helps maintain the extremely low temperatures required for these applications.

8. Building and Construction: In construction, nano microporous insulation boards are used in building envelopes, particularly in energy-efficient buildings. They provide superior thermal insulation in thin profiles, helping to reduce heating and cooling loads while maximizing usable space.

9. Laboratory and Medical Equipment: These insulation boards are used in laboratory and medical equipment that requires precise temperature control, such as in autoclaves, incubators, and sterilizers. Their ability to maintain stable temperatures is critical in these applications.

10. Fire Protection: Nano microporous insulation boards are used in fire protection systems, such as in fire doors, safes, and protective barriers. Their high thermal resistance helps prevent the spread of fire and protects critical structures and components.

11. Shipping and Packaging: These boards are used in thermal packaging solutions for shipping temperature-sensitive goods, such as pharmaceuticals, food, and electronics. They help maintain the required temperature range during transportation.

12. Renewable Energy: In renewable energy systems, such as solar thermal power plants and biomass boilers, nano-microporous insulation boards are used to enhance thermal efficiency and reduce energy losses.

Nano Microporous Insulation Board Packaging

Our Nano Microporous Insulation Board is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Nano Microporous Insulation Board FAQs

Q1: What sizes and thicknesses are available for nano microporous insulation boards?

A: Nano microporous insulation boards are available in various sizes and thicknesses to meet specific application requirements. Custom sizes can often be produced to fit particular needs.

Q2: How does the thermal conductivity of nano microporous insulation boards compare to other insulation materials?

A: Nano microporous insulation boards typically have much lower thermal conductivity compared to conventional insulation materials, such as fiberglass or mineral wool. This makes them more effective at reducing heat transfer and improving energy efficiency.

Q3: How is the quality of nano microporous insulation boards verified?

A: Quality is verified using techniques such as thermal conductivity testing, mechanical testing for compressive strength, moisture resistance testing, and scanning electron microscopy (SEM) for morphological examination.

English

English Española

Española Deutsch

Deutsch Français

Français Italiano

Italiano