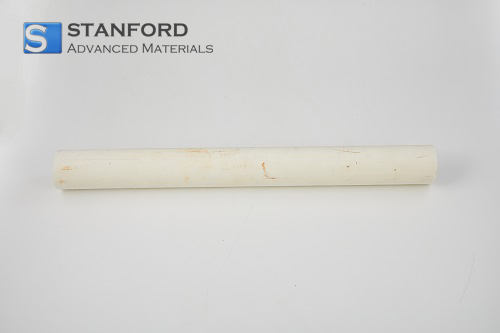

Mullite Ceramic Tube Description

Mullite Ceramic Tube is a cylindrical component made from mullite (3Al2O3·2SiO2), which is a silicate mineral composed of aluminum, silicon, and oxygen. This material is prized in various high-temperature applications due to its exceptional properties, such as high resistance to thermal shock, good mechanical strength, stability in high-temperature environments, and low thermal expansion.

Mullite Ceramic Tube Specifications

|

Chemistry content

|

|

Al2O3

|

SiO2

|

TiO2

|

Fe2O3

|

CaO·MgO

|

K2ONa2O and others

|

|

62.50%

|

34.50%

|

0.10%

|

0.80%

|

0.90%

|

1.30%

|

|

Mechanical

|

Units of Measure

|

SI/Metric

|

(Imperial)

|

|

Density

|

gm/cc (lb/ft3)

|

2.8

|

-175

|

|

Porosity

|

% (%)

|

0

|

0

|

|

Color

|

-

|

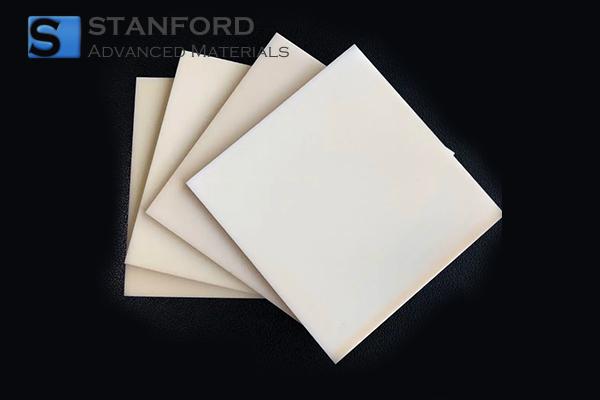

off-white

|

off-white

|

|

Flexural Strength

|

MPa (lb/in2x103)

|

180

|

-26

|

|

Elastic Modulus

|

GPa (lb/in2x106)

|

151

|

-22

|

|

Shear Modulus

|

GPa (lb/in2x106)

|

-

|

-

|

|

Bulk Modulus

|

GPa (lb/in2x106)

|

-

|

-

|

|

Compressive Strength

|

MPa (lb/in2x103)

|

1310

|

-190

|

|

Hardness

|

Kg/mm2

|

1070

|

-

|

|

Fracture Toughness KIC

|

MPa•m1/2

|

2

|

-

|

|

Maximum Use Temperature

|

°C (°F)

|

1650

|

-3000

|

|

(no load)

|

|

Thermal

|

|

Thermal Conductivity

|

W/m•°K (BTU•in/ft2•hr•°F)

|

6

|

-42

|

|

Coefficient of Thermal Expansion

|

10–6/°C (10–6/°F)

|

5.4

|

-3

|

|

Electrical

|

|

Dielectric Strength

|

ac-kv/mm (volts/mil)

|

9.8

|

-245

|

|

Dielectric Constant

|

@ 1 MHz

|

5.8

|

5.8

|

|

Dissipation Factor

|

@ 1 kHz

|

0.003

|

0.003

|

|

Volume Resistivity

|

ohm•cm

|

>1013

|

>1013

|

Mullite Ceramic Tube Applications

1. Thermocouple Protection Tubes: In high-temperature environments, Mullite tubes are commonly used to protect thermocouples. Their excellent thermal stability and resistance to thermal shock make them ideal for monitoring temperatures in furnaces, kilns, and other high-heat processes.

2. Furnace Tubes: In industrial furnaces, mullite ceramic tubes are used as furnace or muffle tubes due to their ability to withstand high temperatures and resist chemical corrosion. They help maintain a controlled atmosphere within the furnace.

3. Heat Exchangers: Mullite ceramic tubes are used in heat exchangers, particularly in applications involving high temperatures and corrosive environments. Their thermal stability and low thermal expansion make them suitable for maintaining structural integrity under thermal cycling.

4. Insulating Components: Mullite tubes are used as insulating components in electrical and electronic devices. Their good electrical insulation properties make them ideal for use in high-voltage and high-temperature applications.

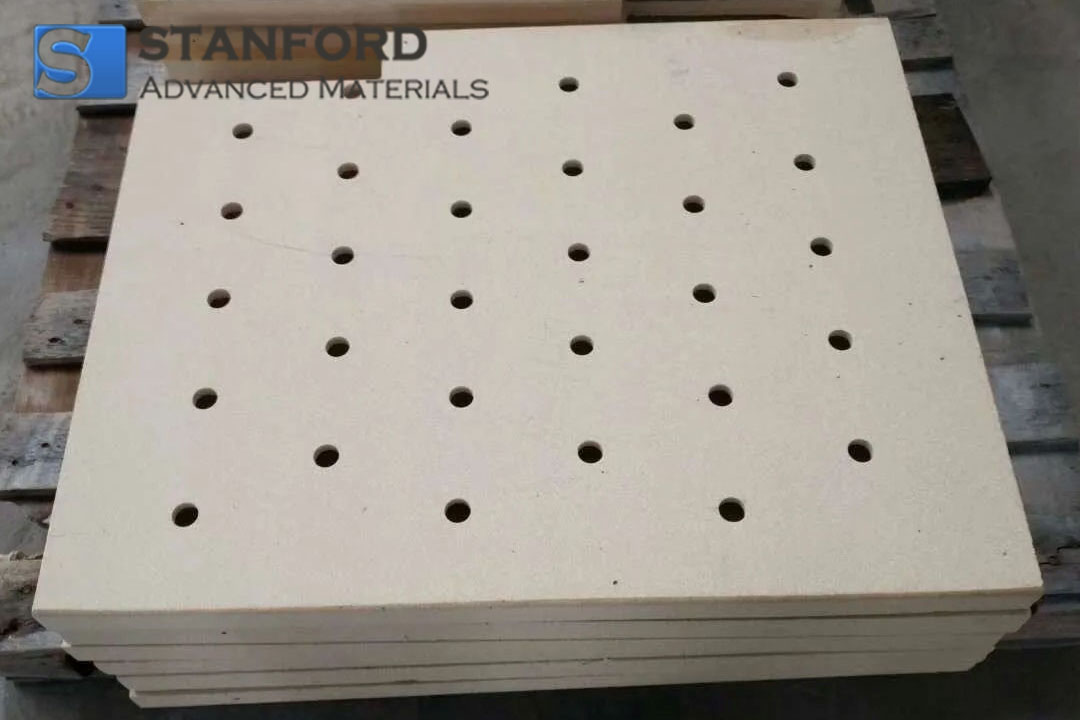

5. Kiln Furniture: Mullite ceramic tubes are used as kiln furniture in the ceramics industry. They support ceramic products during firing, ensuring even heat distribution and preventing deformation.

6. Chemical Processing: Mullite tubes are used in chemical processing equipment, especially in reactors and other systems that involve high temperatures and corrosive chemicals. Their resistance to chemical attack and high-temperature stability make them suitable for such environments.

7. Aerospace Applications: In aerospace engineering, mullite ceramic tubes are used in thermal protection systems and as structural components in high-temperature environments, such as in jet engines or rocket nozzles.

8. Casting Industry: Mullite ceramic tubes are used in the casting industry, particularly in investment casting, where they serve as molds or part of the gating system to withstand high-temperature molten metals.

9. Gas and Fluid Conveyance: Mullite tubes are sometimes used to convey gases or fluids at high temperatures, especially in environments where chemical inertness and thermal stability are critical.

Mullite Ceramic Tube Packing

Our Mullite Ceramic Tube is carefully handled during storage and transportation to preserve the quality of our product in its original condition.