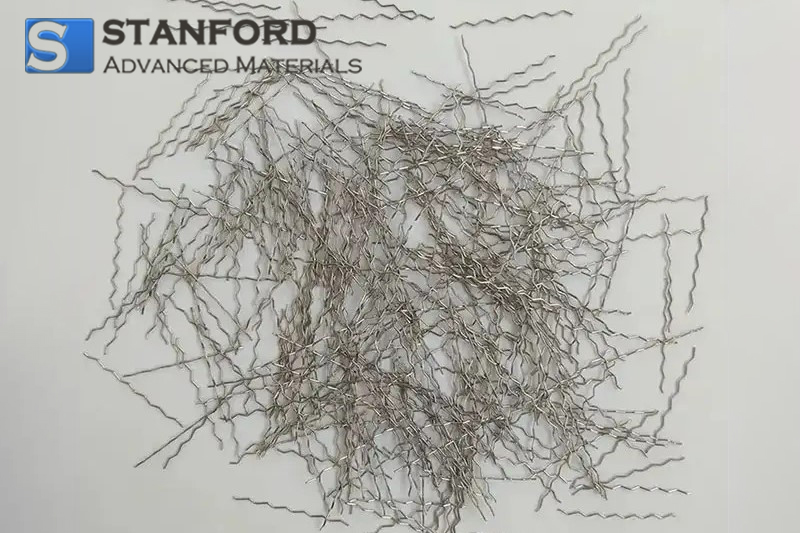

Nickel Sintered Mesh Description:

Nickel offers high strength, firm structure, good and uniform permeability, and high thermal and corrosion resistance properties. Due to this, Nickel sintered metal porous products have been extensively utilized in the several industrial fields including petrochemical, chemical, metallurgy, electrical and electric, environmental, pharmaceutical industry, aeronautical, and space industries.

Nickel sintered cloth consists of mesh layers that are strongly bonded by diffusion annealing. Following our customer’s requirements in regards to stability and filtration, single and multiple mesh layers are blended with perforated sheets or fiber felt. In addition to guaranteed high mechanical stability, diffusion annealing sustains the filtration properties of cloth. The versatile production processes enable us to produce and fabricate Nickel sintered meshes following individual customer’s specification and application requirements.

Nickel Sintered Mesh Properties:

-Produced by combining multi-layer mesh, rolling, and elevated temperature sintering

-High permeability with good pore structure and uniform distribution

-Great mechanical strength

-Excellent thermal and corrosion resistance

-Easy processing

-Good regeneration ability with simple and smooth opening

Nickel Sintered Mesh Applications:

-Hydraulic oils filtration

-Polymer industry

-Storage silos

-Food Processing

-Driers & Coolers

-Chemical products filtration

-Fluidization of bulk materials in gravity conveyors

-Pharmaceuticals and cosmetic

-Fuel processing, etc.