- Products

- Categories

- Blog

- Podcast

- Application

- Document

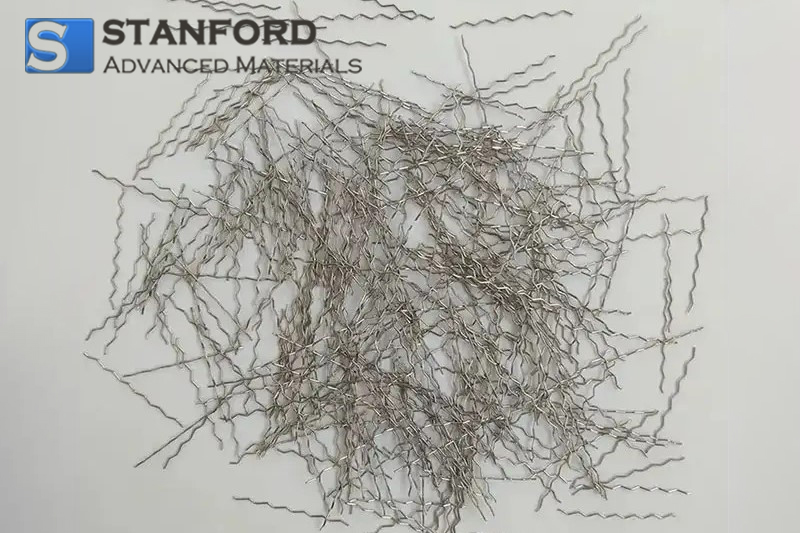

MF2359 Chopped Stainless Steel Fiber

| Catalog No. | MF2359 |

| Material | Stainless steel |

| Color | Grey |

| Fiber Fineness | Fiber Fineness |

Chopped Stainless Steel Fiber has uniform meshes, no broken wires, and no loopholes. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Molybdenum Mesh.

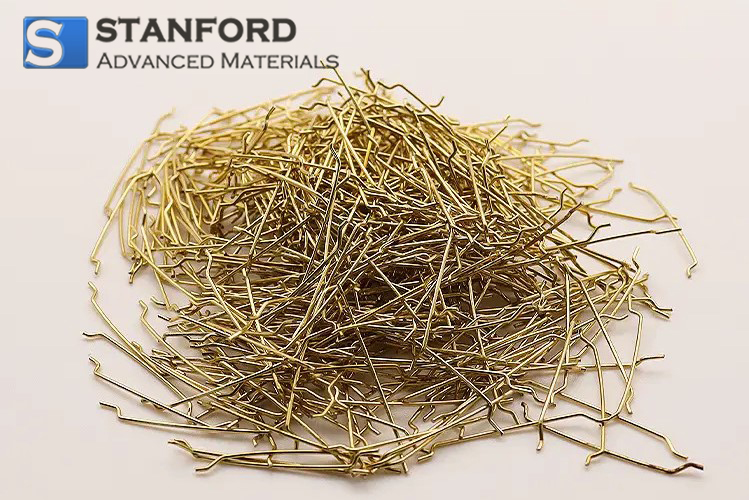

Related products: Brass Fiber, FeCrAl Fiber Filter, Stainless Steel Fiber, Nickel Fiber.

INQUIRY

Add to Inquiry List

Description

Specification

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!