- Products

- Categories

- Blog

- Podcast

- Application

- Document

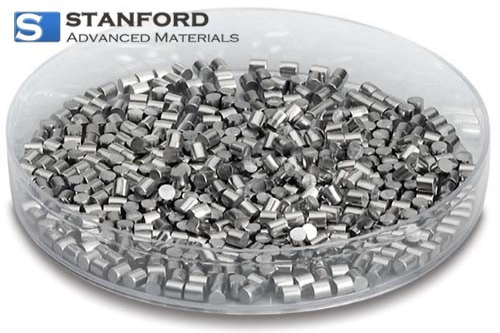

MN3977 Manganese Bronze Bar (863 Bronze)

| Catalog No. | MN3977 |

| Material | Manganese Bronze (863 Bronze) |

| Standard | ASTM B505 |

| Shape | Bar |

| Size | Customized |

Manganese Bronze Bar (863 Bronze) can handle heavy loads and high speeds when properly lubricated. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Manganese Bronze Bar (863 Bronze).

Related products: Manganese Bronze Rod (863 Bronze), Nickel Aluminum Bronze (AMS 4880), Nickel Aluminum Bronze (ASTM B150), Nickel Aluminum Bronze (AMS 4640)

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!