VD0631 Manganese Nickel (Mn/Ni) Evaporation Materials

| Catalog No. | VD0631 |

| Material | Manganese Nickel (Mn/Ni) |

| Purity | 99.9% ~ 99.99% |

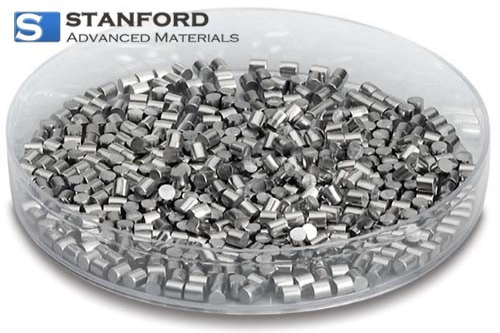

| Shape | Powder/ Granule/ Custom-made |

Manganese Nickel (Mn/Ni) Evaporation Material is made of high-purity Manganese Nickel, which can be used for electron beam and thermal evaporation. Stanford Advanced Materials (SAM) specializes in producing high-purity Manganese Nickel (Mn/Ni) Evaporation Materials.

Related products: Aluminum Nickel (Al/Ni) Evaporation Materials, Manganese (Mn) Evaporation Materials

Manganese Nickel (Mn/Ni) Evaporation Materials Description

Stanford Advanced Materials (SAM) specializes in producing high-purity evaporation materials with high quality for use in semiconductor, chemical vapor deposition (CVD), and physical vapor deposition (PVD) display and optical applications. The unique synergy between our engineering, manufacturing, and analytical teams has allowed us to produce industry-leading evaporation materials.

Our Mn/Ni evaporation materials are precision-engineered, offering exceptional purity, consistency, and reliability for applications in electronics, optics, and beyond. Explore the potential of these materials for your thin-film deposition needs.

Manganese Nickel Evaporation Materials Specifications:

|

Materials |

Manganese Nickel |

|

Density |

7.2-8.9g/cm3 |

|

Melting Point |

1246-1455℃ |

|

Purity |

99.9% |

Manganese Nickel Evaporation Materials Features:

High Purity: Our Mn/Ni evaporation materials are crafted with a focus on purity, minimizing impurities to ensure the highest quality thin films.

Accurate Composition: The composition ratios of Manganese (Mn) and Nickel (Ni) are meticulously controlled to meet your precise deposition requirements, ensuring reliable results.

Uniform Film Thickness: Achieve excellent control over thin-film thickness, ensuring uniformity across large substrate areas, which is critical for many applications.

Excellent Thermal Stability: Mn/Ni materials exhibit outstanding thermal stability during deposition, preventing particle ejection and ensuring smooth, defect-free film formation.

Versatile Applications: Suitable for a wide range of applications, including magnetics, optics, electronics, and surface engineering.

Custom Solutions: We offer customization options to tailor the Mn/Ni evaporation materials to your unique specifications and application needs.

Manganese Nickel Evaporation Materials Applications:

Our Manganese Nickel Evaporation Materials are employed in various high-tech industries, including:

-

Magnetic Devices: Used in the production of magnetic thin films for sensors, data storage, and magnetic coatings.

-

Semiconductor Manufacturing: Ideal for semiconductor fabrication processes, including thin-film deposition for integrated circuits.

-

Optical Coatings: Utilized in creating optical coatings for lenses, mirrors, and filters in optics and photonics applications.

-

Surface Engineering: Applied to modify surface properties, enhance wear resistance, and reduce friction in various engineering applications.

-

Research and Development: Essential for R&D projects involving thin-film deposition, materials science studies, and academic research.

Manganese Nickel Evaporation Materials Packing

Our Manganese Nickel (Mn/Ni) Evaporation Materials are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage caused during storage or transportation.

Why Choose Our Manganese Nickel Evaporation Materials?

-

Quality Assurance: Our Mn/Ni evaporation materials undergo rigorous quality control processes to meet and exceed industry standards.

-

Technical Expertise: Our team of experts boasts extensive knowledge in thin-film deposition technology and offers dedicated technical support and guidance tailored to your specific applications.

-

Custom Solutions: We understand that one size doesn't fit all. We provide customizable Mn/Ni evaporation materials solutions to meet your unique thin-film deposition requirements, ensuring precision and performance.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!