- Products

- Categories

- Blog

- Podcast

- Application

- Document

NK4735 Incoloy A286 Rod

| Catalog No. | NK4735 |

| UNS No. | S66286 |

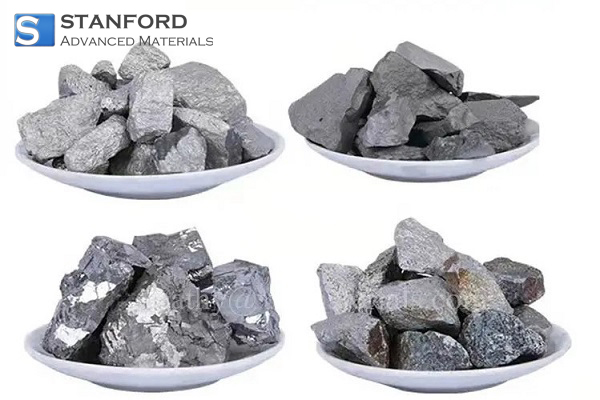

| Material | Ni, Fe, Cr, Ti |

| Density | 7.92 g/cm3 |

| Melting Point | 1370~1430 ℃ |

Incoloy A-286 is an iron-nickel-chromium alloy with additions of molybdenum and titanium. Stanford Advanced Materials (SAM) offers high-quality Incoloy A286 Rod with competitive pricing.

Related products: Incoloy A286 Wire, Spherical Hastelloy X Powder (UNS N06002) for 3D Printing, Alloy C22 (Hastelloy C22) Plate, Alloy C22 (Hastelloy C22) Bar, Hastelloy X Powder (Alloy X, UNS N06002)

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!