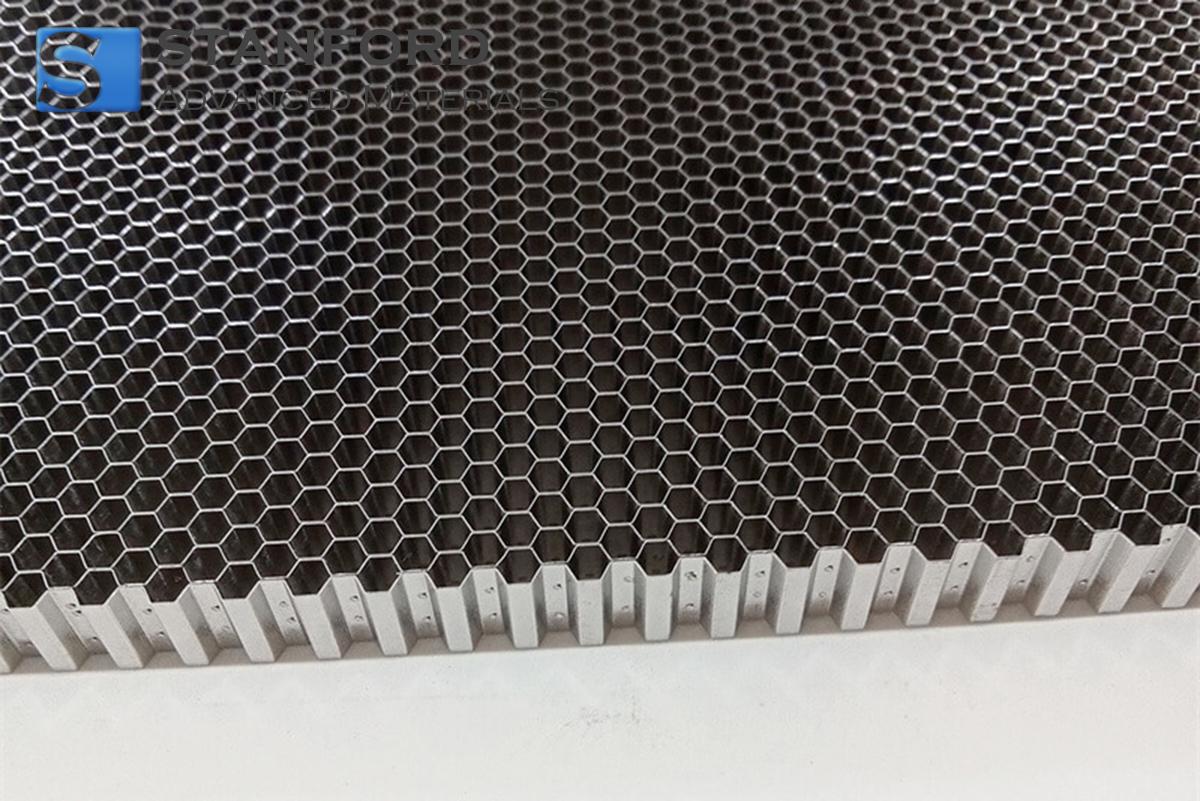

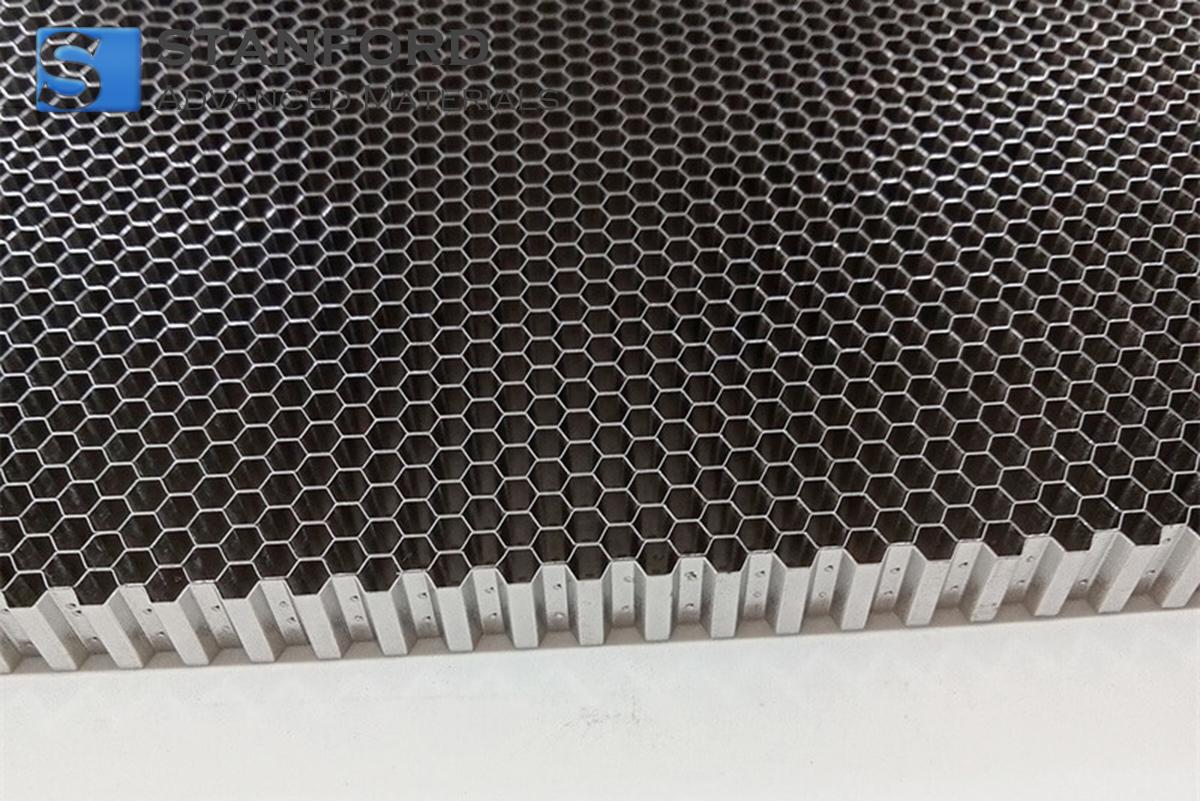

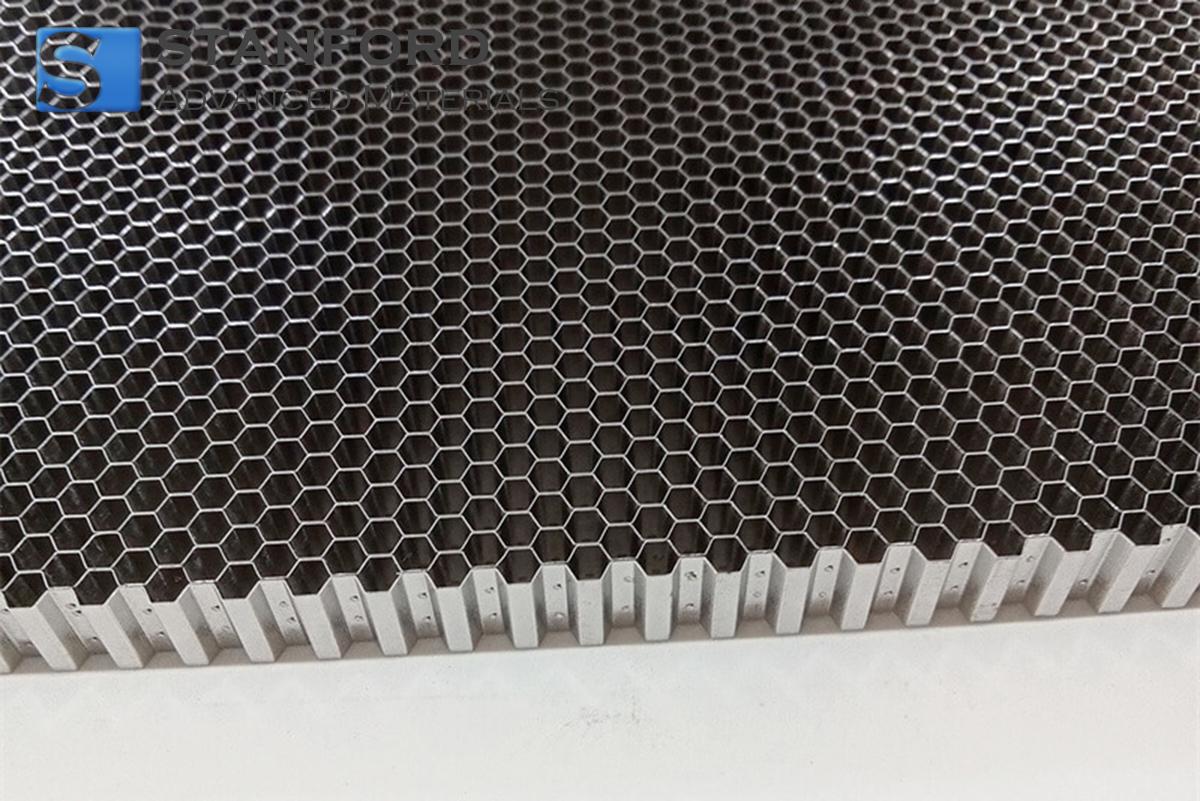

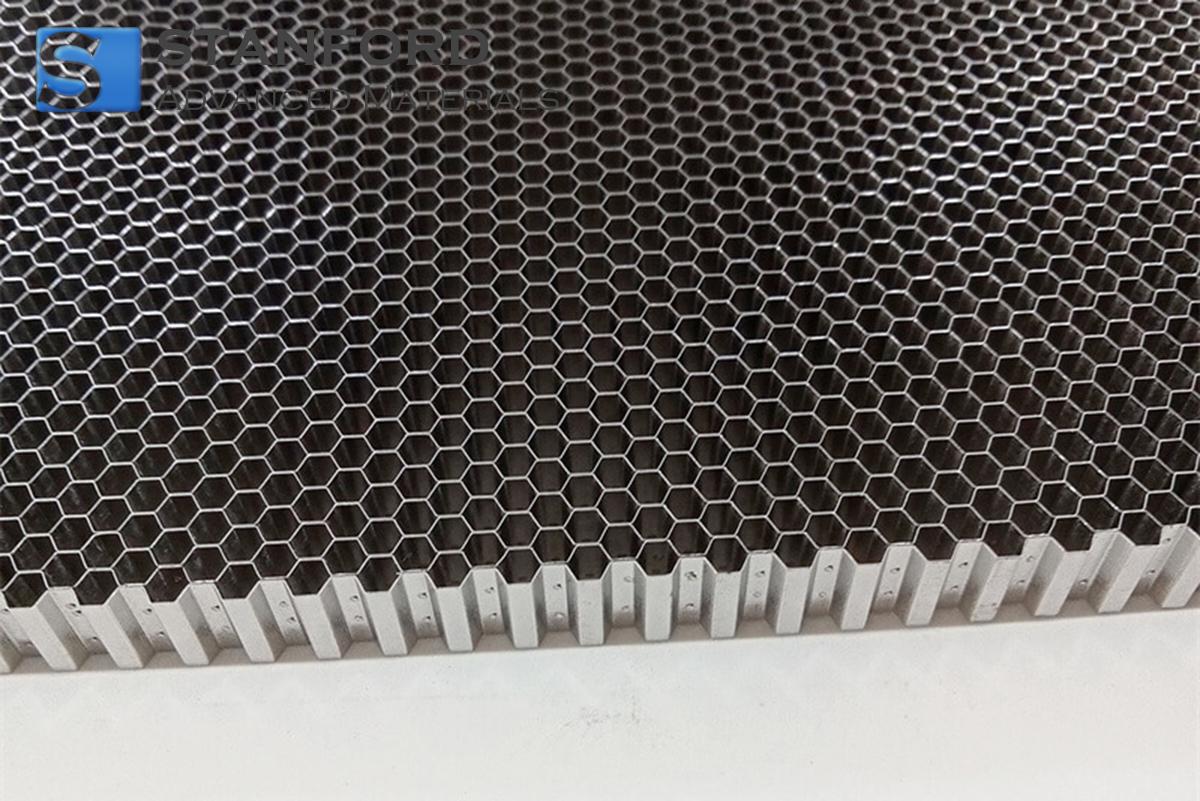

Haynes 230 Honeycomb Description

Haynes 230 Honeycomb is a nickel-based superalloy known for its high strength, excellent oxidation resistance, and superior thermal stability at elevated temperatures. When formed into a honeycomb structure, it becomes a lightweight material with high mechanical strength and excellent heat and corrosion resistance, ideal for demanding applications, especially in aerospace, power generation, and industrial environments.

Haynes 230 Honeycomb Specification

|

Material

|

Haynes 230

|

|

Shape

|

Square, hex, or customized

|

|

Board Thickness

|

.001″- .011″, or customized

|

|

Cell Size

|

1/64 to 3/16″

|

|

Finish

|

electroless nickel plating, tin plating, powder coating, paints

|

|

Dimensions

|

Customized

|

Chemical Composition (%)

|

Ni

|

C

|

Mn

|

Si

|

P

|

Cr

|

Co

|

Fe

|

Al

|

W

|

Mo

|

Cu

|

Ti

|

|

Bal.

|

0.05-0.15

|

0.3-1.0

|

0.25-0.75

|

≤0.03

|

20-24

|

<5

|

<3

|

0.2-0.5

|

13-15

|

1-3

|

<0.5

|

<0.1

|

Haynes 230 Honeycomb Application

Jet engine components: Used in combustor liners, exhaust nozzles, and heat shields, where high-temperature performance is critical.

Spacecraft thermal shields: Provides insulation and protection against extreme heat during re-entry.

Gas turbines: Used in combustors, transition ducts, and heat exchangers for land-based turbines due to its ability to withstand high-temperature oxidation.

Steam turbines: Ideal for applications where temperature and mechanical stress cycles are extreme.

Furnace linings and heat shields: Ensures durability and stability in high-temperature industrial environments.

Chemical processing equipment: Resistant to oxidation and carburization, making it suitable for use in harsh chemical environments.

Exhaust systems and heat shields: Provides lightweight, high-temperature solutions for racing engines and specialized vehicles.

Haynes 230 Honeycomb Packaging

Our Haynes 230 Honeycomb is carefully handled during storage and transportation to preserve the quality of our product in its original condition. Wood cages to avoid damage to your products during shipping.

FAQs

Q1: Why is Haynes 230 Honeycomb preferred for high-temperature applications?

Haynes 230 maintains strength and stability even at temperatures above 1100°C (2000°F). It resists oxidation, carburization, and thermal fatigue, making it ideal for environments with extreme heat and cyclic thermal stresses.

Q2: How does the honeycomb structure enhance performance?

The honeycomb design provides a high strength-to-weight ratio, making it lightweight while retaining structural integrity. This design improves thermal insulation and minimizes material usage without compromising strength.

Q3: Can Haynes 230 Honeycomb be welded or fabricated?

Yes, Haynes 230 is known for its good fabricability. It can be welded, brazed, and formed into complex shapes, including honeycomb panels, making it suitable for custom designs.