- Products

- Categories

- Blog

- Podcast

- Application

- Document

CM4009 High Pressure Methanol Synthesis Catalyst

| Catalog No. | CM4009 |

| Material | Cu-Zn-Al2O3-Auxiliaries etc. |

| Size | φ5x(4-6), φ9x(5-7) |

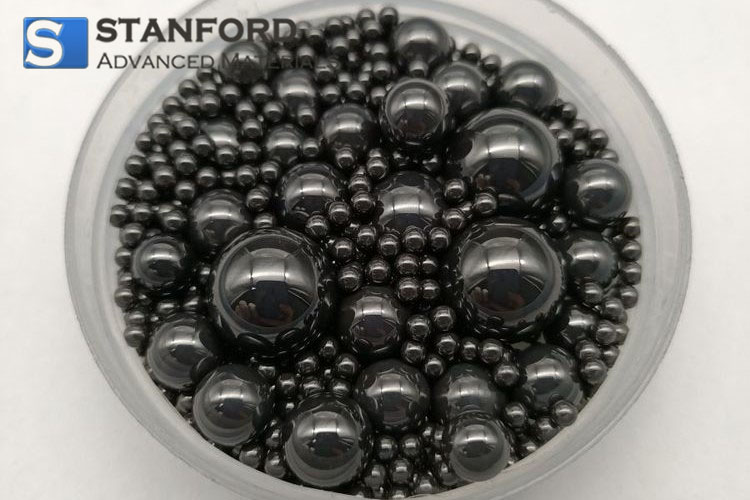

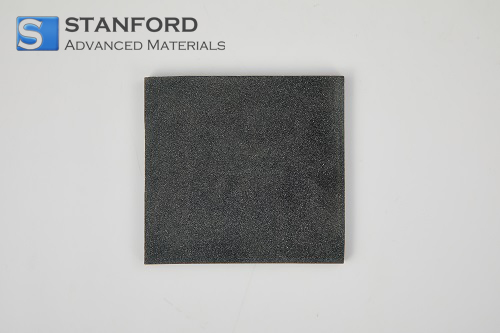

| Appearance | Black Metallic Glossy Cylinder |

| Working Pressure | 12.0-30.0Mpa |

| Reaction Temperature | 200-300℃ |

High Pressure Methanol Synthesis Catalyst has a high conversion rate, good low-temperature activity, high-pressure resistance and high space velocity. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Catalysts.

Related products: Medium Pressure Methanol Synthesis Catalyst, Low Pressure Methanol Synthesis Catalyst, Alcohol Catalyst

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!