The Power of Sound: Exploring Ultrasonic Cleaners in Industrial Applications

Quick Guide:

2 Introduction to Ultrasonic Cleaning Machine

3 Ultrasonic Cleaner’s Applications

4 Case Studies: Specific Uses of Ultrasonic Cleaning Machines in Industries

1 Introduction

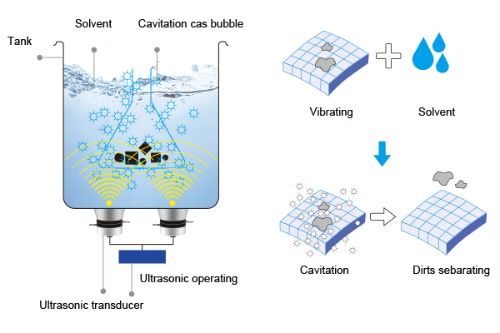

Ultrasonic waves are mechanical waves with extremely short wavelengths, so named because the lower boundary of their frequency band exceeds the range of human hearing. Because of its cavitation effect, ultrasonic waves in the liquid medium will cause the liquid to form hollow microbubbles. These bubbles rapidly expand and close, resulting in huge pressure. This leads to emulsification and can break some hard impurities, so it is often used in cleaning applications. Ultrasonic cleaners are widely used in daily life, scientific research experiments, and industrial production due to their excellent cleaning effect. In this article, we will discuss the principle of ultrasonic cleaning machines and industrial applications, to provide a reference for your purchase.

2 Introduction to Ultrasonic Cleaning Machine

2.1 The Nature of Ultrasound and The Working Principle of Ultrasonic Cleaning Machine

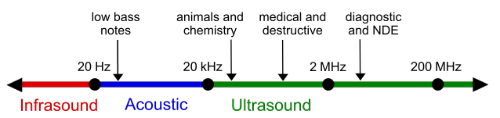

In the air, ultrasonic waves refer to a wavelength belows 2cm, and a frequency exceeds 20kHz mechanical waves. These wavelengths are very short, and below the general lower limit of human hearing (2cm), so people call these inaudible mechanical waves ultrasound.

Ultrasound follows the same laws in the medium of reflection, refraction, diffraction, scattering, and other propagations, just like infrasound and audible sound waves, without any fundamental differences. But the wavelength of ultrasound is very short, only a few centimeters, or even a few thousandths of a millimeter.

Fig. 1 Frequency Range of Ultrasound

Compared with other waves, ultrasound has many characteristics:

Propagation characteristics – The wavelength of ultrasound is very short; typically, obstacles are many times larger than the wavelength of ultrasound many times. Consequently, the penetration of ultrasound is poor, its diffraction ability is inferior, and it is easy to scatter. Ultrasonic waves propagate in a straight line in a uniform medium but are difficult to diffract. The shorter the wavelength, the more significant this characteristic becomes. In addition, according to Rayleigh's law of scattering, the intensity of the scattered wave is inversely proportional to the fourth power of the wavelength. Since the ultrasonic wavelength is extremely short, the scattering will be very serious, and the penetration is not good.

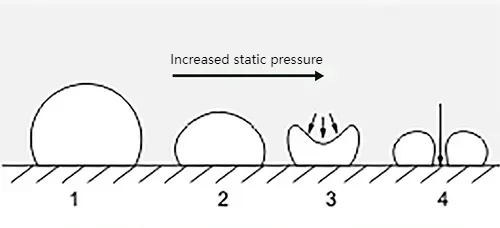

Cavitation - When ultrasonic waves propagate through a medium, there is a positive and negative alternating cycle. In the positive phase, ultrasonic waves compress the medium’s molecules, changing the original density of the medium and increasing it. In the negative phase, the molecules are made sparse, further dispersing them and reducing the medium's density. When ultrasonics of sufficiently high-intensity act on a liquid medium, the average distance between the molecules exceeds what is needed to maintain the medium's critical molecular distance, causing the medium to fracture and form microbubbles. These small cavities rapidly expand and close, making the liquid particles occur between the violent impact, thus generating thousands to tens of thousands of atmospheric pressures. This violent interaction between the particles plays a good role in mixing, so that the two immiscible liquids (such as water and oil) emulsification, and accelerate the dissolution of solutes. Bubble bursting generated by the small but powerful shock waves and micro-jets can also effectively strip and remove dirt and pollutants on the object's surface. This kind of ultrasonic action in the liquid is caused by various effects known as ultrasonic cavitation, which is also the ultrasonic cleaning machine can play a role in cleaning the principle.

Fig. 2 Cavitation

2.2 Structure of Ultrasonic Cleaning Machine

1. Ultrasonic generator

The ultrasonic generator is one of the core components of the ultrasonic cleaning machine, mainly responsible for generating high-frequency electrical energy. It converts alternating current into high-frequency electrical energy (usually between 20kHz and 40kHz) and transmits it to the ultrasonic transducer.

2. Ultrasonic transducer

Ultrasonic transducer is usually made of piezoelectric materials (such as piezoelectric ceramics), so it is also known as a piezoelectric transducer. It consists of a power transformer and rectifier system, oscillator, propellant, dynamic rate amplifier, and output transformer. It converts the high-frequency electrical energy generated by the ultrasonic generator into mechanical vibration. The transducer is fixed at the bottom or side wall of the cleaning tank, converting electrical energy into high-frequency mechanical vibration.

3. Cleaning tank

A cleaning tank is used to contain the cleaning fluid and cleaning items to be cleaned container. It is usually made of stainless steel and other corrosion-resistant materials to prevent the cleaning fluid and dirt on the tank from corrosion. The tank can also be installed on the heating and temperature control devices to control the temperature of the cleaning solution, stainless steel tanks, and box frame pads between the vibration-damping device. The size and shape of the cleaning tank can be customized according to different cleaning needs.

4. Vibrating plate

The vibrating plate is usually fixed on the bottom or side wall of the cleaning tank, connected to the ultrasonic transducer. The plate transmits the mechanical vibration generated by the transducer evenly into the cleaning fluid, creating a cavitation effect.

5. Cleaning fluid

Cleaning fluid is the medium of the cleaning process, usually consisting of water and the appropriate amount of detergent. The choice of cleaning fluid depends on the material to be cleaned and the nature of the dirt. The right cleaning fluid can improve the effect of ultrasonic cleaning.

6. Control panel

Control panel regulates and controls the working parameters of the ultrasonic cleaning machine, including ultrasonic frequency, power, cleaning time, and temperature. Modern ultrasonic cleaners are usually equipped with digital display and programming functions so that users can accurately control the cleaning process. The panel is equipped with a power inlet socket and fuse at the back. The power supply of the ultrasonic cleaner must be installed with an overcurrent protection circuit to ensure the safety of use.

7. Heating system (optional)

Some ultrasonic cleaners are equipped with a heating system for heating the cleaning solution. Heating can improve the cleaning efficiency, especially for greasy dirt, heated cleaning solution can more effectively dissolve and remove dirt.

8. Filtration system (optional)

The filtration system is used to remove the impurities in the cleaning solution and maintain the cleanliness of the cleaning solution. The system can extend the service life of the cleaning solution and improve the cleaning effect.

9. Drainage system

The drainage system is used to empty the cleaning fluid in the cleaning tank, which facilitates the replacement of the cleaning fluid and the cleaning of the cleaning tank. It usually includes a drain valve and piping.

Fig. 3 Ultrasonic Cleaning Machine Structure and Principle

3 Ultrasonic Cleaner’s Applications

3.1 Industrial Applications

Ultrasonic cleaning machines are widely used in various industries.

l The manufacturing industry for product surface cleaning treatment often uses ultrasonic cleaning to achieve the purpose of completely removing small impurities.

l In the electronics industry, ultrasonic cleaning machines are mainly used to clean electronic components and circuit boards. Electronic components in the manufacturing process are easily contaminated with a variety of tiny dust and pollutants, ultrasonic cleaning can effectively remove these tiny particles, to ensure the cleanliness and quality of components.

l In the automobile manufacturing process, many parts such as engine components, transmission components, fuel injection systems, etc. need to maintain a high degree of cleanliness. Ultrasonic cleaning machines can completely remove these parts on the oil, metal shavings, and other impurities, to improve the quality of assembly and vehicle performance.

l In the field of precision machinery manufacturing, many parts require a very high degree of cleanliness. Ultrasonic cleaners can remove tiny impurities from the surface and interior of these parts to ensure their accuracy and performance.

l In the manufacture of optical lenses and instruments, ultrasonic cleaners are used to remove dust and fingerprints from lenses to ensure clarity and precision.

l In the steel manufacturing process, the steel surface often has oxidized skin, grease, and other pollutants. Ultrasonic cleaners can remove these contaminants quickly and efficiently, enhancing the surface quality of steel.

In application scenarios that require extremely high precision as well as cleanliness, ultrasonic cleaners can meet higher cleanliness requirements.

l Ultrasonic cleaners are widely used in the medical industry to clean surgical instruments and other medical equipment. Its efficient and thorough cleaning ability can ensure the sterility of medical equipment and prevent the occurrence of infection. Pharmaceutical equipment and containers require strict cleaning standards. Ultrasonic cleaners can efficiently clean reactors, agitators, and other equipment to ensure a pollution-free and safe pharmaceutical production process.

l In the cleaning of food processing equipment, an ultrasonic cleaning machine can effectively remove residual food debris and stains, to ensure the cleanliness of equipment and food safety.

l The aerospace industry has extremely high requirements for the cleanliness of parts. Ultrasonic cleaning machines can be used to clean a variety of complex shapes and structures of aviation parts to ensure their reliability in the harsh environment.

l In addition to the above industries, ultrasonic cleaning machines are also widely used in watchmaking, jewelry processing, chemical laboratories, and other fields, any need for efficient, precise cleaning occasions can use ultrasonic cleaning technology.

In the manufacturing industry, the use of ultrasonic cleaning machines for product cleaning can enhance productivity, and improve product quality. Ultrasonic cleaning can penetrate small crevices and complex structures, to achieve a higher degree of cleanliness. At the same time, the precision parts can ensure their surface integrity, and reduce parts loss. In addition, ultrasonic cleaning machines using water-based cleaning fluid, reduce the use of chemicals and reduce environmental pollution. Therefore, ultrasonic cleaning has become an important cleaning method in industrial manufacturing production. Stanford Advanced Materials (SAM) offers a wide range of ultrasonic cleaners for large-scale industrial applications and can provide you with the right choice of equipment based on the size of your industry, footprint, and efficiency requirements. Fig. 4 shows a Five Tanks Ultrasonic Cleaner with Semi-automated Transfer System.

Fig. 4 Five Tanks Ultrasonic Cleaner with Semi-automated Transfer System

3.2 Life Applications

Ultrasonic cleaner is not only widely used in industries, but also has many important applications in daily life. It uses the cavitation effect of ultrasonic waves to efficiently and thoroughly clean a variety of items, saving time and effort.

l Ultrasonic cleaning machines can efficiently clean the dirt and grease on jewelry, watches, and other accessories to restore their original luster, and can penetrate small crevices to thoroughly remove dirt that is difficult to clean by hand.

l It can also thoroughly clean eyeglass lenses and frames to avoid scratching and damaging the lens surface.

l Ultrasonic cleaning machines can be used to clean tableware and kitchenware, especially those items with complex shapes and tiny crevices, such as knives, forks, spoons, and strainers. Ultrasonic cleaning removes stubborn grease and food residues and ensures hygiene.

l Dental appliances used at home, such as toothbrush heads, dentures, and braces, are prone to accumulating bacteria and dirt. Ultrasonic cleaners can effectively clean these appliances, providing better oral hygiene.

l Physiotherapy appliances used at home, such as massage heads, cupping devices, and physiotherapy electrode pads, can be cleaned by ultrasonic cleaning to remove residues after use, keeping the appliances hygienic and safe.

l Beauty tools such as razors, barber scissors, make-up brushes, and manicure tools can be cleaner and more hygienic after ultrasonic cleaning, reducing the risk of skin infections.

l Cosmetic containers such as eyeshadow palettes, powder cases, lipstick tubes, etc., can be cleaned with an ultrasonic cleaner to remove residual cosmetics and dirt and keep the containers clean.

l Ultrasonic cleaners can also be used to clean artifact collections, etc. to maintain the original appearance and value of the items.

In addition to stronger cleaning power, the most significant advantage of Ultrasonic cleaning in the application of life is to reduce the use of powerful chemical cleaning agents that have a certain degree of danger, improve safety at the same time also reduce the pollution of the environment.

Fig. 5 A Kind of Ultrasonic Glasses Cleaning Machine

3.3 Scientific Research Applications

Ultrasonic cleaners have a wide range of applications in the field of scientific research, mainly to support a variety of research and experiments using their high efficiency, precision, and non-destructive cleaning characteristics.

l Laboratory glassware, plastic appliances, metal tools, etc. need to maintain a high degree of cleanliness, so as not to contaminate the results of experiments. Ultrasonic cleaners can effectively remove residues, chemicals, and particles attached to these utensils to ensure the cleanliness of the experimental apparatus.

l In materials science and bioscience research, the sample preparation process often needs to remove surface contaminants. Ultrasonic cleaners can be used to clean the surface of the sample to ensure the purity of the sample and the accuracy of the experimental results.

l In chemical analysis experiments, the sample pre-treatment step requires an efficient cleaning process. Ultrasonic cleaners can quickly clean sample vials, reactors, and other experimental containers, reducing contaminant interference with analytical results.

l In metallurgy and materials research, cleaning of metal samples is a very important step. Ultrasonic cleaners can effectively remove grease, oxides, and other impurities from metal surfaces, ensuring clean samples and accurate results.

l Electronic components used in scientific research, such as microelectronic chips, sensors, and circuit boards, need to be kept highly clean. Ultrasonic cleaners can remove tiny particles and contaminants from the surface of these components to ensure their performance and reliability.

l In optical experiments, lenses, prisms, optical fiber, and other optical components need to maintain a high degree of transparency and cleanliness. Ultrasonic cleaners can efficiently remove dust and fingerprints from the surface of these components to ensure the accuracy of optical experiments. The preparation and processing of nanomaterials require the removal of impurities and unreactants from their surfaces to ensure the accuracy of their properties and research results. Ultrasonic cleaners can penetrate deep into the microstructure of nanomaterials and remove impurities completely.

l In biology and medical research, cell culture apparatus, microscope slides, and other biological samples require rigorous cleaning. Ultrasonic cleaners remove residues and contaminants from the surface of biological samples, ensuring the reliability of experimental results. Microfluidic chips are widely used in biomedical and chemical analysis, and their microstructures are easily contaminated. Ultrasonic cleaners can efficiently clean the tiny channels and structures of these chips to ensure their function and performance.

l In archaeological research, ancient artifacts and fossil samples need to be cleaned with great care to avoid damage. Ultrasonic cleaners gently but effectively remove soil and sediment from the surface of these samples, preserving their original condition.

The use of ultrasonic cleaners in scientific research allows for the thorough cleaning of complex objects in a short period without mechanical damage to delicate instruments and samples, preserving their integrity. The use of machine control for cleaning work makes it easy to realize the automation of the cleaning process, reduce human error, and improve the efficiency of the experiment. At the same time, it reduces the dependence on strong chemical cleaners, the use of water-based cleaning fluids, environmental protection, and safety.

Fig. 6 Laboratory Ultrasonic Cleaners for Instrument Cleaning

4 Case Studies: Specific Uses of Ultrasonic Cleaning Machines in Industries

Here are some case studies of the use of ultrasonic cleaners in industrial manufacturing.

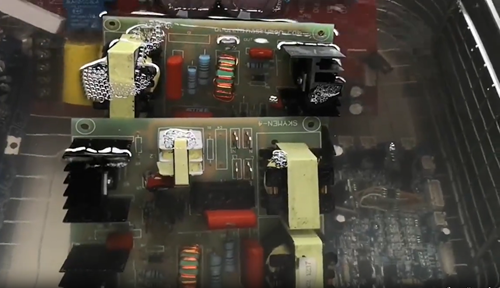

4.1 Enhancing PCB Maintenance with Ultrasonic Cleaning in the Electronics Industry

PCB circuit board cleaning is commonly used for ultrasonic cleaning. PCB circuit board (Printed Circuit Board) is one of the indispensable components of electronic equipment, used to mechanically support and electrically connect the electronic components. PCB through the formation of conductive paths on a non-conductive substrate, connectivity, and other circuitry graphics to achieve the connection between electronic components and communication.

PCB component welding flux is divided into three categories: water-soluble, rosin-type, and no-clean type. The first two types are more frequently used and often require ultrasonic cleaning, although alcohol brushing is also common. In principle, no-clean flux should not require cleaning. However, most manufacturers worldwide still clean electronic components soldered with no-clean type flux. Especially with high-density PCBs and IC pins, if they are not cleaned or if ultrasonic cleaning is not used, dust can accumulate between the high-density lines and pins. This accumulation can lead to short circuits when the environment becomes humid, and these failures might resolve and disappear on their own once it dries, making them difficult to detect. Therefore, most electronics manufacturers consistently use ultrasonic cleaning for PCBs to prevent these issues.

Fig. 7 Ultrasonic Cleaning Machine to Clean PCB

4.2 Enhancing Cleaning Efficiency with Ultrasonic Technology in the Hardware Sector

Compared with a variety of other cleaning methods, ultrasonic cleaning machine shows great superiority, especially in the specialization, group production enterprises. These enterprises have gradually used ultrasonic cleaning machines to replace traditional immersion, brushing, pressure washing, vibration cleaning steam cleaning, and other processes. Ultrasonic machines offer high efficiency and a high degree of cleanliness due to the sound wave propagation in the medium, which results from penetration and cavitation effects. This makes it easier to clean parts and components with complex shapes, internal cavities, and fine holes. Moreover, ultrasonic cleaning machines are versatile, suitable for automotive wheel hubs, plated and vacuum-plated parts, motor parts, bearings, die-cast parts, stamping parts, eyeglasses, stainless steel tableware, compressors, watch parts, precision textile equipment, precision molds, gears, crankshafts, and other precision components. Precision molds, gears, crankshafts, valves, radiators, and other precision parts are efficiently cleaned of oil, wax, and debris during the production process using ultrasonic cleaning. This technology is also extensively used for cleaning electronic circuit boards, bearing parts, optical lenses, automotive parts, vacuum ion coating components, hardware plating parts, audio magnetic heads, precision hardware parts, medical equipment, liquid crystal displays, and aviation machinery, making it essential in various industries' specialized cleaning applications.

4.3 Enhancing Pre and Post-Treatment Processes in the Plating Industry with Ultrasonic Cleaning

Ultrasonic cleaning is primarily used in the plating industry for a wide range of components, including electroplating parts, vacuum plating parts, locks, motor parts, bearings, die-cast parts, stamping parts, watch cases and straps, eyeglass frames, stainless steel tableware, compressors, precision textile equipment, precision molds, gears, crankshafts, valves, radiators, and other precision metal parts. It effectively removes oil, wax, and debris from all types of metal parts during production and processing. Ultrasonic cleaning in this sector is categorized into two main types: pre-treatment and post-treatment cleaning. Pre-treatment involves cleaning various hardware parts to remove polishing wax, processing oils, and debris. Post-treatment focuses on removing residual plating solutions and various residues from the plating process.

5 Conclusion

Ultrasonic cleaning technology has shown significant application value in the industry, life, and scientific research due to its efficient, deep, and gentle cleaning characteristics. This technology utilizes the cavitation effect generated by ultrasonic waves to effectively remove dirt, grease, and other impurities from the surface and internal structure without damaging the item being cleaned, which is especially suitable for cleaning items with complex shapes and tiny crevices. In industrial manufacturing, ultrasonic cleaning machine improves production efficiency and product quality, reduce the use of chemical cleaners, and reduce environmental pollution. In daily life, it provides individuals with a safe, environmentally friendly, and efficient way of cleaning. In the field of scientific research, ultrasonic cleaning technology ensures the high cleanliness requirements of experimental apparatus and samples, supporting precise scientific research. Therefore, whether from the perspective of enhancing cleaning efficiency, safeguarding the performance of products and equipment, or considering from the perspective of environmental protection and safety, an ultrasonic cleaning machine is an advanced cleaning tool worthy of extensive promotion and application.

References:

[1] Fabrication and Performance Tests of an Ultrasonic Cleaning System for Solar-cell Wafers[J]. Journal of the Korean Society of Manufacturing Technology Engineers,2019,28(4).

[2] Escrig J ,Woolley E ,Rangappa S , et al. Clean-in-place monitoring of different food fouling materials using ultrasonic measurements[J]. Food Control,2019,104.

[3] M S K . Research : Ensuring Cavitation in a Medical Device Ultrasonic Cleaner.[J]. Biomedical instrumentation & technology,2019,53(4).