Specific Modulus of Engineering Materials

Description of Specific Modulus

Specific modulus is a fundamental property in material science that quantifies the stiffness of a material in relation to its density. It is calculated by dividing the elastic modulus (Young's modulus) by the material's density. This ratio provides insight into how much load a material can bear for a given weight, making it an essential factor in designing lightweight and strong structures.

Importance in Material Selection

When selecting materials for engineering applications, especially where weight is a critical factor, the specific modulus serves as a key parameter. Materials with a high specific modulus are preferred in industries such as aerospace, automotive, and sports equipment manufacturing because they offer high stiffness without adding unnecessary weight.

Examples of Specific Modulus in Materials

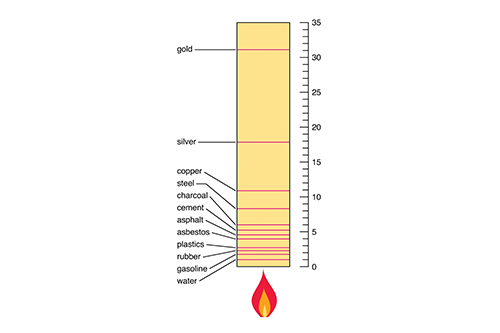

Different materials exhibit varying specific moduli, influencing their suitability for specific applications. Here are some common materials and their typical specific modulus values:

- Aluminum Alloys: Known for their lightweight and reasonable stiffness, making them ideal for aircraft structures.

- Titanium Alloys: Offer higher specific modulus compared to aluminum, suitable for high-performance aerospace components.

- Carbon Fiber Composites: Provide exceptional specific modulus, widely used in racing cars and sports equipment for their superior strength-to-weight ratio.

- Steel: While having a high absolute modulus, its density results in a lower specific modulus, limiting its use in weight-sensitive applications.

Comparative Table of Specific Modulus

|

Material |

Elastic Modulus (GPa) |

Density (g/cm³) |

Specific Modulus (GPa·cm³/g) |

|

69 |

2.7 |

25.56 |

|

|

110 |

4.5 |

24.44 |

|

|

Carbon Fiber Composite |

230 |

1.6 |

143.75 |

|

Steel |

200 |

7.85 |

25.48 |

|

Magnesium Alloy |

45 |

1.74 |

25.86 |

For more information, please check Stanford Advanced Materials (SAM).

Frequently Asked Questions

What is specific modulus used for?

Specific modulus is used to evaluate the efficiency of materials in applications where weight and stiffness are critical, such as aerospace and automotive industries.

How is specific modulus calculated?

It is calculated by dividing the elastic modulus of a material by its density, providing a measure of stiffness relative to weight.

Why is carbon fiber composite's specific modulus higher than metals?

Carbon fiber composites have a high elastic modulus combined with low density, resulting in a superior specific modulus compared to metals.

Can specific modulus indicate a material's strength?

While specific modulus relates to stiffness, it does not directly measure strength. Both properties are important but distinct in material selection.

Is specific modulus the same as strength-to-weight ratio?

They are related concepts, but specific modulus specifically refers to stiffness-to-weight ratio, whereas strength-to-weight ratio pertains to the material's strength relative to its weight.