Heating Furnaces for Crystal Growth Application

Introduction

As an important piece of equipment in the crystallization industry and other processing industries, heating furnaces provide a supportive environment for temperature control. By converting different forms of energy into heat and transferring it to the material using thermal radiation and convection, temperature changes during the process can be controlled. For thecrystal growth and surface deposition process, the temperature control directly determines the product quality obtained, so the heating furnace equipment production process can be understood. Its role in crystal growth and surface deposition of knowledge for a detailed introduction can help you solve some doubts when choosing heating furnace equipment. You can also seek advice from the Stanford Advanced Materials (SAM) professionals if needed.

1. Melt Growth Method

1.1 Czochralski Method

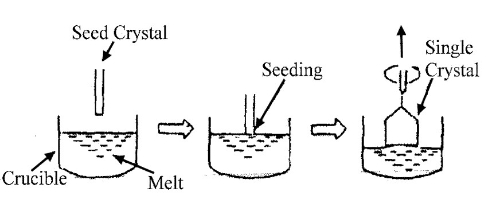

The Czochralski method (CZ method) is one of the most important methods used to grow monocrystalline silicon and other single-crystal materials. The role of the heating furnace in the CZ method is crucial as it provides the high-temperature environment required to ensure uniformity and stability of the molten material, which in turn affects the quality of the final crystal.

The basic steps of the Czochralski method involve melting the feedstock, i.e., heating the feedstock (e.g., polysilicon) until it is completely molten. Crystallization is then induced by touching the molten surface with a thin rod (seed crystal) and gradually crystallizing the molten material on the seed crystal by rotating and slowly lifting it. By precisely controlling the lifting and rotating speeds while growing the crystals, the crystals gradually grow to form single crystals.

Fig. 1 The Process of The Czochralski Method

The role of the heating furnace in the CZ method includes:

1. Provide a stable high-temperature environment:

Temperature control: The heating furnace must be able to operate stably at high temperatures above 1400°C, and usually needs to be accurately controlled at around 1500°C to maintain the molten state of materials such as silicon.

Temperature uniformity: In order to avoid temperature gradients in the melt, the heating furnace must provide a uniform heating environment to ensure temperature consistency during crystal growth.

2. Maintaining the purity of the melt:

Crucible material: Crucibles are usually manufactured using high-purity quartz or other inert materials to avoid impurities from entering the melt.

Atmosphere control: Reduce the effects of oxidation and other gas-phase reactions on crystal growth by using a protective atmosphere (e.g., argon) or vacuum.

3. Thermal field design:

Thermal Field Configuration: By optimizing the position of the heating elements and the layout of the insulation material around the crucible, the thermal field distribution can be precisely controlled, affecting the flow and temperature distribution of the melt, and thus the quality and growth rate of the crystals.

Thermal gradient control: During the crystal growth process, the furnace must maintain an appropriate thermal gradient to promote directional crystal growth and reduce crystal defects.

4. Dynamic temperature adjustment:

During crystal pulling: During the process of lifting and pulling crystals, the furnace needs to dynamically adjust the temperature according to the growth rate and diameter changes of the crystals in order to ensure stable growth and consistent shape of the crystals.

Crystallization and annealing: After the crystal growth is completed, the heating furnace also needs to gradually reduce the temperature for annealing treatment to reduce the internal stresses and defects in the crystals and to improve the mechanical and electrical properties of the crystals.

The most common types of furnaces used in the CZ method are resistance furnaces and induction furnaces. Most CZ crystal growth equipment uses resistance heating furnaces because of their high-temperature control accuracy and relatively simple structure. Common heating elements include graphite and molybdenum wire, which provide stable and uniform heating. Induction heating furnaces, on the other hand, provide rapid warming and cooling for processes that require rapid temperature changes. Generating uniform eddy current heating in the crucible through electromagnetic induction helps maintain the temperature uniformity of the melt. Fig. 6 and Fig. 7 show the structure of vertical and horizontal heating furnaces respectively.

Example Analysis

1. Growth of silicon monocrystals: In the semiconductor industry, the CZ method is commonly used to grow high-purity silicon monocrystals, which are used as the base material for the manufacture of integrated circuits. Heating furnaces must provide a precisely controlled high-temperature environment during this process to ensure the purity and uniformity of the silicon melt, thus producing defect-free, large-size single crystals.

2. Growth of oxide single crystals: The CZ method is also used to grow oxide single crystals (e.g., sapphire), which have important applications in the optical and electronics industries. The high-temperature stability of the heating furnace and the control of the temperature gradient are essential to minimize stresses and defects in the crystals.

1.2 Bridgman Method

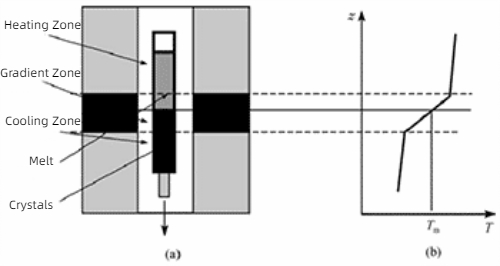

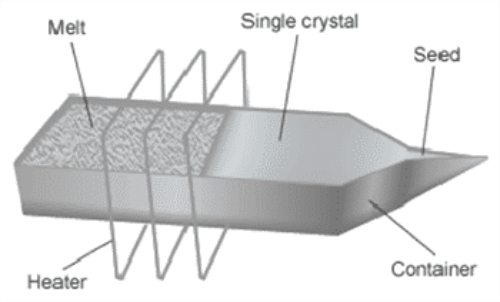

The Bridgman method involves loading polycrystalline or high-purity powdered material into a crucible, which is then heated to a molten state in a furnace. Next, the molten material is gradually cooled and induced to crystallize by seed crystals by slowly moving the crucible or by creating a temperature gradient in the furnace, eventually forming single crystals.

The role of the heating furnace in the Bridgman method includes:

1. Provide a stable high-temperature environment:

Molten material: The heating furnace must be able to operate stably at high temperatures to ensure complete melting of the material. For example, growing silicon crystals requires temperatures over 1414°C, while growing molybdenum crystals requires temperatures in excess of 2623°C.

Temperature uniformity: The furnace needs to provide uniform heating to ensure that the melt temperature is stabilized and to avoid temperature fluctuations that could interfere with crystal growth.

2. Control of temperature gradients:

Hot and cold zones: The design of the heating furnace must be able to create distinct hot and cold zones within the furnace to produce the desired temperature gradient. The hot zone is usually at the top of the crucible, while the cold zone is at the bottom of the crucible or in the growth zone.

Adjustment of the temperature gradient: By adjusting the power and position of the heating elements, the size and position of the temperature gradient can be precisely controlled, which directly affects the growth rate and quality of the crystals.

3. Dynamic temperature control:

Crucible movement: In the Bridgman method, the crucible is usually moved downward at a constant speed, allowing the molten material to gradually crystallize through the temperature gradient zone. The furnace needs to maintain stable temperature control during crucible movement.

Directional solidification: The furnace must ensure directional solidification of the material from the molten zone to the solid zone to minimize crystal defects and stresses and to improve crystal quality.

4. Melt purity is maintained:

Crucible material selection: The crucible material must be inert and resistant to high temperatures, such as quartz, graphite, or platinum, to avoid contamination of the melt by impurities.

Atmosphere control: An inert atmosphere (e.g., argon) or vacuum can be maintained in the heating furnace to prevent oxidation and impurities from entering the melt and to ensure crystal purity.

The heating furnaces commonly used in the Bridgman method are mainly vertical and horizontal. Vertical heating furnaces usually have upper and lower-zoned heating elements, which can accurately control the temperature of each zone and are suitable for the temperature gradient requirements of the Bridgman method. It is suitable for most Bridgman crystal growth, including semiconductor and oxide materials. A horizontal heating furnace is suitable for lateral temperature gradient control and crystal growth by moving the crucible horizontally. It is suitable for the growth of specific materials, such as certain high-temperature superconducting materials and metal crystals.

Fig. 2 Structure of Vertical Heating Furnace and Temperature Distribution

Fig. 3 Schematic Diagram of Horizontal Bridgman Method Growth Device

Example Analysis

1. Growing CdTe crystals: Cadmium telluride (CdTe) crystals are widely used in photodetectors and solar cells. In the Bridgman method, a heated furnace is required to melt CdTe at about 1092°C and provide a precise temperature gradient during slow cooling to form high-quality single crystals.

2. Growing silicon crystals: High-purity silicon crystals are critical in electronic and optoelectronic devices. When the Bridgman method is used to grow silicon crystals, the furnace needs to maintain a temperature above 1414°C and provide the proper temperature gradient to ensure directional solidification and minimize defects.

2. Chemical Vapor Deposition (CVD)

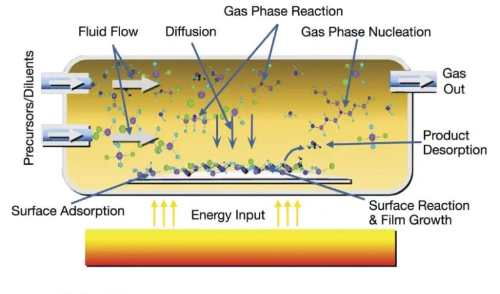

Chemical vapor deposition (CVD) is a widely used technique for the fabrication of high-quality, high-performance films and coatings. A heated furnace plays a key role in the CVD process by providing the necessary temperature conditions to facilitate the chemical reaction of gas-phase reactants on the substrate surface to produce the desired deposited layer.

The basic steps of CVD involve the introduction of gaseous precursors into a reaction chamber where the substrate is typically heated to a higher temperature to facilitate the chemical reaction. The gaseous precursor chemically reacts on the surface of the substrate to form a solid film. The gaseous by-products from the reaction are then expelled from the reaction chamber.

Fig. 4 Principle of CVD

The role of the heater in CVD includes:

1. Providing the reaction temperature:

Substrate heating: The furnace is used to heat the substrate to the desired reaction temperature, typically between 200°C and 1200°C, depending on the material being deposited and the process requirements.

Reaction zone heating: The furnace maintains the temperature of the reaction zone to ensure that the gas-phase reactants can effectively react with the substrate surface.

2. Promotion of chemical reaction:

Reaction kinetics: Temperature is a key factor affecting the kinetics of chemical reactions. By controlling the temperature, the heating furnace optimizes the decomposition and reaction rate of precursors to improve deposition efficiency and film quality.

Film Characterization Control: Different deposition temperatures can affect film characteristics such as crystal structure, composition, and stress. Precise temperature control helps to achieve specific film properties.

3. Ensure uniform deposition:

Temperature uniformity: The furnace must provide uniform temperature distribution to ensure consistent thickness and composition of the deposited layer and to avoid inhomogeneities and defects in the film.

Dynamic temperature adjustment: In the deposition process, the temperature may need to be adjusted according to different stages and process requirements, the heating furnace should have a good dynamic response.

Tube furnaces, chamber furnaces, and induction furnaces are commonly used in chemical vapor deposition processes. Tube furnaces usually consist of a long quartz or ceramic tube in which the substrate is placed and heated by an external heating element. They are suitable for CVD processes in small-scale and laboratory conditions, providing good temperature control and atmosphere control. Chamber furnaces are similar in construction to conventional furnaces with an internal heating chamber in which the substrate and precursor react. The chamber furnace is suitable for processing large substrates and mass production, providing a uniform temperature environment and high processing capacity. Induction heating furnaces utilize electromagnetic induction to heat substrates and are typically used for processes that require rapid warming and cooling. The fast-heating rate makes them suitable for high-temperature and short deposition processes and requires less substrate material.

Example Analysis

1. Silicide deposition: CVD deposition of silicide films is usually carried out at elevated temperatures (~600-900°C), where a heated furnace provides the temperature environment needed to ensure that precursors (e.g., silanes and metal-organic compounds) react efficiently to produce a homogeneous silicide film.

2. Diamond Thin Film Deposition: Diamond CVD deposition is typically carried out at elevated temperatures of 900-1200°C. A heated furnace ensures that methane and hydrogen precursors form diamond crystal structures on the substrate.

3. Gallium Nitride Thin Film Deposition: Gallium Nitride CVD deposition is required at elevated temperatures of approximately 1000°C. A heated furnace ensures that ammonia and gallium precursors react to produce high-quality GaN thin films.

3. Molecular Beam Epitaxy (MBE)

Molecular Beam Epitaxy (MBE) is a precisely controlled thin film growth technique used to produce high purity, low defect semiconductor materials and other functional films. A heated furnace plays a key role in the MBE process by providing the necessary temperature control to ensure the evaporation of the source material and the precise regulation of the substrate temperature for high-quality thin film deposition.

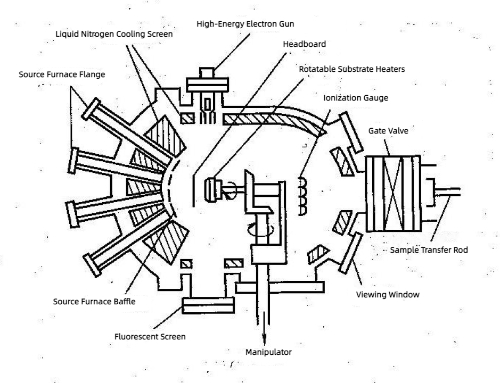

MBE technology forms epitaxial thin films by evaporating beams of atoms or molecules from the source material to the substrate surface in a high or ultra-high vacuum environment. The basic steps include forming the molecular beams by heating the source material, causing it to evaporate or sublimate. Heating the substrate to an appropriate temperature to facilitate the growth of the epitaxial film. Controlling the flow rate of the molecular beam and the substrate temperature to achieve high-precision deposition of the epitaxial film.

Fig. 9 Schematic of MBE Growth Chamber Structure

The role of the heater in MBE includes:

1. Source material heating:

Evaporation source: The heating furnace is used to heat the source material (e.g., gallium arsenide, silicon, aluminum, etc.) to evaporate or sublimate it in a vacuum environment to form a uniform atomic or molecular beam.

Temperature control: Evaporation temperatures vary from material to material, usually between 500°C and 1500°C. The temperature of the evaporation process can be controlled by the furnace. The heating furnace requires precise temperature control to ensure a stable evaporation rate and vapor flow density.

2. Substrate heating:

Temperature regulation: Substrate temperature is critical to the quality and crystal structure of epitaxial films. The furnace is used to heat the substrate to a specific temperature, typically between 200°C and 800°C, to promote the migration and alignment of atoms on the substrate surface to form a high-quality epitaxial film.

Uniformity: The heating furnace must ensure uniformity of the substrate temperature to avoid temperature gradients that can lead to uneven film thickness or crystal defects.

3. Thermal deposition control:

Multiple Source Heating: MBE systems are typically equipped with multiple heating furnaces for heating different source materials. Temperature control and synchronized regulation of these furnaces are critical to achieve accurate deposition of multilayer structures or alloy films.

Dynamic Adjustment: During the deposition process, the temperature of the heating furnace can be dynamically adjusted to optimize the quality and properties of the film as needed for film growth.

Different heating devices are used for MBE processes that require heating and evaporation of the source material as well as maintaining the substrate temperature during the deposition process. The Knudsen Cell (K-Cell), a commonly used evaporation source for MBE, contains the source material inside, which is evaporated by either resistive or electron-beam heating. It provides stable evaporation rates and precise temperature control and is suitable for epitaxial growth of high-purity materials. Another type of heating equipment used to evaporate the source material is the electron beam heating furnace. The E-beam furnace utilizes an electron beam to bombard the surface of the source material and heat it to the evaporation temperature. It is suitable for high melting point materials and is characterized by high heating efficiency and fast temperature response.

In contrast, the substrate heater is usually integrated into the sample holder of the MBE equipment and heats the substrate either by resistance heating or radiation heating. Substrate heaters provide precise temperature control and a uniform heating environment for a wide range of substrate materials and deposition needs.

Example Analysis

1. GaAs (Gallium Arsenide) Epitaxial Growth: When MBE grows GaAs thin films, the heater is used to heat the Arsenic and Gallium source materials to the appropriate evaporation temperatures (~400-600°C and ~1200-1500°C), respectively, and to heat the substrate to ~600°C to promote the formation of high-quality GaAs epitaxial layers.

2. AlGaAs/GaAs multilayer structure: Multiple heating furnaces in the MBE system heat the aluminum, gallium, and arsenic source materials separately to achieve high-precision deposition of AlGaAs/GaAs multilayer structures by precisely controlling the evaporation rate and substrate temperature.

Conclusion

Heating furnaces play a pivotal role in various crystal growth processes, such as the Czochralski method, Bridgman method, Chemical Vapor Deposition (CVD), and Molecular Beam Epitaxy (MBE). Their ability to provide stable high-temperature environments, maintain purity, control temperature gradients, and dynamically adjust temperatures is crucial for producing high-quality single crystals. Whether used in the semiconductor industry for silicon monocrystals or the production of oxide single crystals, heating furnaces ensure precision and consistency. By understanding the intricacies of these processes and the capabilities of different types of heating furnaces, one can make informed decisions to achieve optimal results in crystal growth. For reliable and high-quality muffle furnaces, Stanford Advanced Materials (SAM) offers a range of options tailored to meet your specific needs.

References:

[1] R. R. Gilman, Czochralski and Floating Zone Crystal Growth of Modern Materials, Springer, 2012.

[2] G. Müller, "Handbook of Crystal Growth: Bulk Crystal Growth," Elsevier, 2014.

[3] Guo Qin-Min, Qin Zhi-Hui. Development and application of vapor deposition technology in atomic manufacturing. Acta Phys. Sin., 2021, 70(2): 028101. doi: 10.7498/aps.70.20201436

[4] R. F. C. Farrow, "Molecular Beam Epitaxy: Applications to Key Materials," Noyes Publications, 1995.

[5] L. L. Chang and K. Ploog, "Molecular Beam Epitaxy and Heterostructures," Springer, 2013.

[6] Lech Pawlowski, "The Science and Engineering of Thermal Spray Coatings," John Wiley & Sons, 2008.

[7] Robert C. Tucker Jr., "Thermal Spray Technology," ASM Handbook, Volume 5A, ASM International, 2013.

[8] Gerd W. Becker, "Industrial Furnaces: Heat Treatment Equipment," Wiley-VCH, 2014.