Fatigue Limit and Material Performance

Introduction to Fatigue Limit

The fatigue limit, also known as endurance limit, refers to the maximum stress a material can withstand for an infinite number of loading cycles without failing. In many engineering applications, materials are subjected to repeated or fluctuating loads, and over time, this can cause failure even if the applied stress is well below the material's ultimate tensile strength. Understanding the fatigue limit is crucial for ensuring the long-term reliability of components exposed to cyclic loading, such as in machinery, automotive parts, and structural elements.

Unlike static loads, which can be analyzed using traditional strength properties, fatigue is a dynamic phenomenon. Even materials with high strength can fail after experiencing numerous cycles of stress and strain, making fatigue a critical consideration in design and material selection.

Factors Affecting Fatigue Limit

Several factors influence the fatigue limit of a material, which makes it a complex phenomenon to predict and control. These factors include:

1. Material Composition and Microstructure:

The internal structure of a material plays a significant role in its fatigue limit. For example, materials with a fine-grained structure tend to exhibit better fatigue resistance than those with a coarse grain structure.

Alloying elements can also affect fatigue performance. For instance, certain alloys, like high-carbon steel, tend to have a lower fatigue limit compared to low-carbon steel.

2. Surface Quality:

The surface finish of a material can significantly impact its fatigue strength. Surface imperfections, scratches, and roughness act as stress concentrators and can initiate cracks under cyclic loading. Polishing or coating surfaces can improve fatigue resistance.

3. Loading Conditions:

The magnitude and nature of the applied load are key factors. A high mean stress (tensile or compressive) reduces the fatigue limit, while compressive loading often increases it. The frequency of loading and whether the load is constant or fluctuating (e.g., sine or square wave loading) also affect the fatigue limit.

4. Temperature:

Elevated temperatures can degrade the material's fatigue performance. High temperatures can lead to softening of materials, reducing their ability to resist cyclic stresses. Conversely, cryogenic temperatures might improve fatigue performance for certain materials like titanium.

5. Corrosion:

Materials exposed to corrosive environments (such as seawater or chemical exposure) often suffer from corrosion fatigue, where the material's surface is weakened, reducing its fatigue limit.

6. Notch Sensitivity:

Materials with high notch sensitivity have a lower fatigue limit. A sharp notch, crack, or defect in the material’s geometry can significantly lower its fatigue strength by concentrating stress and promoting crack initiation.

Application of Fatigue Limit

The fatigue limit is especially critical in industries where materials are subject to repeated or fluctuating loads. Some key applications include:

1. Automotive Industry:

Components like crankshafts, axles, and suspension parts experience cyclic stresses during operation. Ensuring that these parts have sufficient fatigue limits is crucial for vehicle safety and performance.

2. Aerospace:

Aircraft components, such as wing structures, landing gear, and turbine blades, are subjected to extreme cyclic loading during flights. The fatigue limit ensures that these components can withstand the rigors of repeated flights without catastrophic failure.

3. Construction and Structural Engineering:

Building materials like steel beams and bridges experience fluctuating loads from traffic or wind forces. Designers must ensure that these materials have a high fatigue limit to ensure structural integrity and safety over time.

4. Medical Devices:

Certain medical implants, such as joint replacements or stents, experience repetitive loads from body movements. The fatigue limit of these materials is critical to ensure that the implants perform without failure throughout their service life.

5. Energy Sector:

Wind turbine blades, oil drilling equipment, and power plant components are all subject to cyclic stresses from operation. Fatigue analysis ensures that these parts can withstand the mechanical stresses over long operational lifespans.

Fatigue Limit of Different Materials

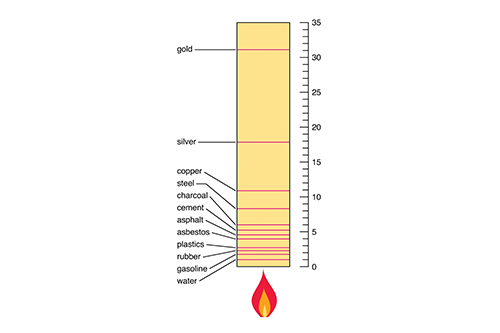

Different materials exhibit varying fatigue limits, which directly influence their suitability for specific applications. Here are the approximate fatigue limits for some common materials:

|

Material |

Fatigue Limit (MPa) |

Notes |

|

Mild Steel |

140 - 210 |

Low-carbon steels have moderate fatigue resistance. |

|

High-Strength Steel |

280 - 450 |

Steel alloys with higher tensile strength often have higher fatigue limits. |

|

500 - 700 |

Excellent fatigue resistance, especially at high temperatures. |

|

|

90 - 250 |

Aluminum alloys have moderate fatigue resistance, often used in aerospace applications. |

|

|

Nickel Alloys (e.g., Inconel) |

450 - 650 |

Nickel-based alloys are highly fatigue-resistant, especially in extreme temperatures. |

|

Cast Iron |

70 - 140 |

Cast iron has a lower fatigue limit due to its brittle nature. |

|

10 - 50 |

Ceramics typically have very low fatigue limits due to their brittleness. |

|

|

Magnesium Alloys |

90 - 160 |

Magnesium alloys exhibit moderate fatigue resistance, used in lightweight components. |

Frequently Asked Questions

What is the difference between fatigue limit and ultimate tensile strength?

The fatigue limit refers to the maximum stress a material can endure for an infinite number of cycles without failure. The ultimate tensile strength is the maximum stress a material can withstand before breaking in a single loading event.

Can fatigue failure be prevented?

While fatigue failure cannot always be completely prevented, it can be delayed by selecting materials with high fatigue limits, improving surface finishes, and designing components to avoid sharp edges and high-stress concentrations.

What is the effect of temperature on the fatigue limit?

Elevated temperatures can reduce the fatigue limit of many materials. For example, metals tend to become softer at high temperatures, which lowers their ability to resist cyclic loading.

How can the fatigue life of a component be increased?

The fatigue life of a component can be increased by using materials with high fatigue limits, improving surface quality, applying surface treatments, and optimizing the design to reduce stress concentrations.

Does every material have a fatigue limit?

Not all materials have a clear fatigue limit. For some materials, such as certain polymers or metals, the fatigue limit may not exist, and the material will fail at lower stresses after a certain number of cycles.