Cerium Zirconium Oxide Nanofiber Description

Cerium Zirconium Oxide Nanofibers are advanced nanomaterials known for their exceptional catalytic activity, high thermal stability, and excellent oxygen storage capacity. These nanofibers exhibit unique properties due to their nanoscale dimensions, including a high surface area-to-volume ratio, which enhances their reactivity and efficiency in various applications. They are highly resistant to sintering and thermal degradation, making them suitable for use in high-temperature environments. Additionally, the incorporation of cerium provides redox properties that are beneficial for catalytic processes, while the zirconium oxide component contributes to structural stability and durability. These combined properties make Cerium Zirconium Oxide Nanofibers ideal for use in automotive catalytic converters, environmental remediation, fuel cells, and various advanced catalytic systems.

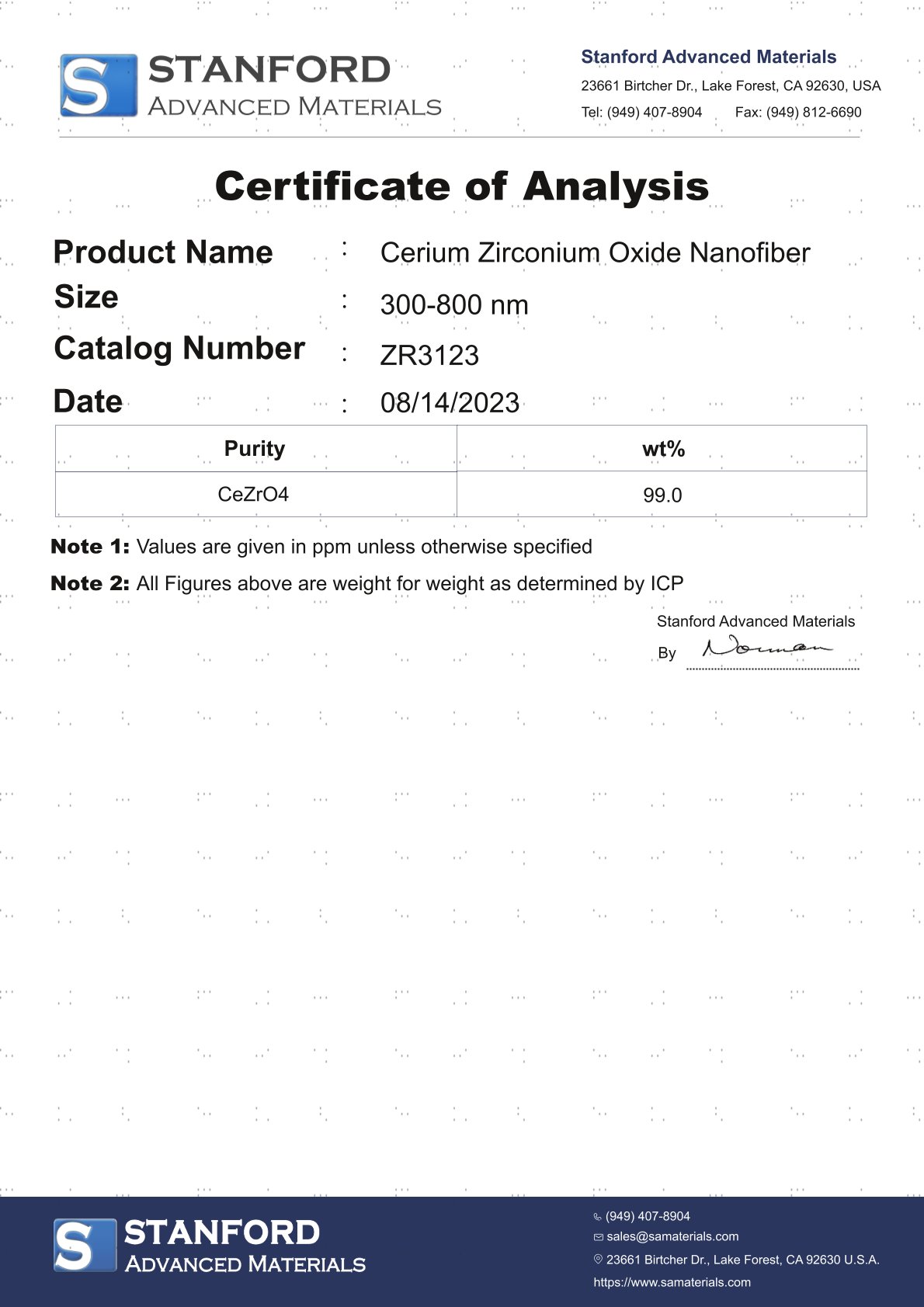

Cerium Zirconium Oxide Nanofiber Specifications

|

Composition

|

CeZr04

|

|

Fiber Diam

|

300-800 nm × 2-hundreds of μm

|

|

Structure

|

Polycystalline nanofibers

|

|

Primary Crystallite Size

|

8 nm (Crystal Phase: tetragonal)

|

|

Surface Area

|

spec. surface area 30-60 m2/g

|

Cerium Zirconium Oxide Nanofiber Applications

1. Automotive Catalytic Converters: Used to reduce harmful emissions by converting pollutants into less harmful substances due to their high catalytic activity and oxygen storage capacity.

2. Environmental Remediation: Applied in processes that remove contaminants from air and water, leveraging their catalytic properties for breaking down pollutants.

3. Fuel Cells: Utilized in solid oxide fuel cells (SOFCs) as an electrode material, providing high ionic conductivity and thermal stability.

4. Catalysis: Employed in various industrial catalytic processes, including chemical synthesis and energy production, owing to their enhanced reactivity and stability.

5. Sensor Technology: Integrated into sensors for detecting gases and other substances, benefiting from their high sensitivity and stability.

6. Energy Storage: Investigated for potential use in energy storage systems, such as batteries and supercapacitors, due to their electrochemical properties.

Cerium Zirconium Oxide Nanofiber Packing

Cerium Zirconium Oxide Nanofiber is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Cerium Zirconium Oxide Nanofiber FAQs

Q1: How are Cerium Zirconium Oxide Milled Nanofibers synthesized?

A: Typically, these nanofibers are synthesized using the electrospinning technique, where a solution containing cerium and zirconium precursors is spun into fibers, followed by calcination to achieve the desired crystalline structure. The fibers are then milled to obtain the necessary length and surface characteristics.

Q2: Can Cerium Zirconium Oxide Milled Nanofibers be customized for specific applications?

A: Yes, the properties of these nanofibers can be tailored by modifying the synthesis process, such as changing the precursor materials, adjusting the electrospinning parameters, or introducing dopants to achieve specific characteristics suitable for various applications.