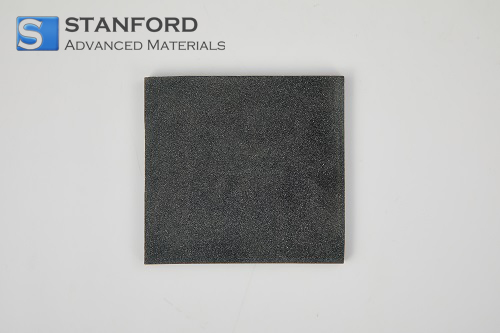

Description of Ceramic Fiber Module

Ceramic fiber is produced from high purity aluminosilicate material through a strictly controlled high-temperature furnace melting and fiberizing process. Ceramic fiber products are white and odorless, which is suitable for high-temperature applications up to 2300°F. Due to the resistance to high temperatures, good thermal stability, and significant energy-saving effects, ceramic fibers are gradually replacing traditional refractory brick refractories. Ceramic fiber modules can be anchored on the industrial furnace to achieve the effect of fire insulation.

Advantages

- Low heat conduction

- Chemical stability

- Excellent tensile strength

- Excellent thermal stability and resistance to shock

- Excellent sound absorption

- Can compensate fiber furnace lining shrinkage

Specifications of Ceramic Fiber Module

|

Code

|

SCFM-950

|

SCFM-1000

|

SCFM-1100

|

SCFM-1200

|

SCFM-1350

|

|

Permanent linear change in heating (%)

|

950°C×24h <-3

|

1000°C×24h <-3

|

1100°C×24h <-3

|

1200°C×24h <-3

|

1350°C×24h <-3

|

|

Heat conductivity coefficient(W/m.k)

|

200°C

|

0.050-0.058

|

|

400°C

|

0.090-0.121

|

|

600°C

|

0.165-0.198

|

|

Slag content (%)

|

<20

|

|

Bulk density(kg/m)

|

180±10; 200±10

|

|

Size(mm)

|

300*300*250

|

Applications of Ceramic Fiber Module

Ceramic fiber modules are fixed on the steel plate of the furnace shell of the industrial kiln for fire protection. These industrial furnaces include:

- Kilns in the petrochemical industry

- Kilns in the metallurgical industry

- Kilns in ceramic and glass industries

- Heat treatment furnace

Ceramic Fiber Module FAQs

Q1: What is a Ceramic Fiber Module?

Answer: A Ceramic Fiber Module is a pre-fabricated insulation unit made from ceramic fiber blanket materials. These modules are designed for use in high-temperature industrial applications and are typically installed in furnaces, kilns, and other high-temperature equipment to provide efficient thermal insulation.

Q2: What are the common applications of Ceramic Fiber Modules?

Answer: Common applications include lining for furnaces, kilns, boilers, incinerators, and other high-temperature industrial equipment. They are used in petrochemical, steel, aluminum, ceramics, and glass industries for thermal insulation and energy efficiency.

Q3: How are Ceramic Fiber Modules manufactured?

Answer: Ceramic Fiber Modules are manufactured by folding, stacking, or compressing ceramic fiber blankets into pre-designed shapes and sizes. These modules are then secured with various hardware systems for easy installation.