Description of ZTA Tube

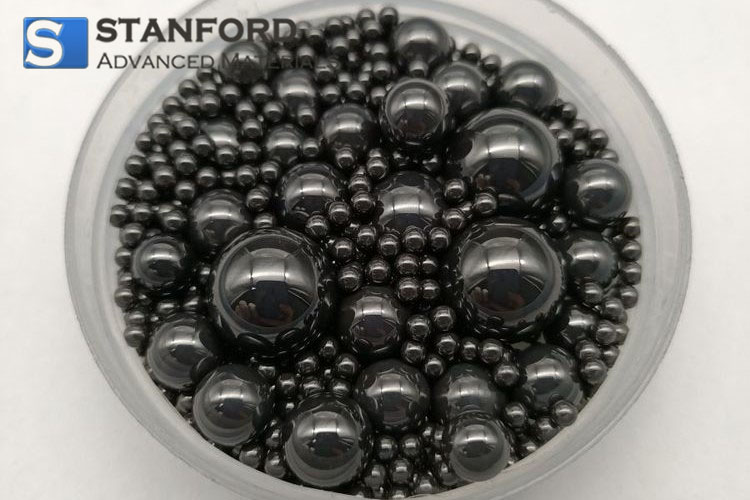

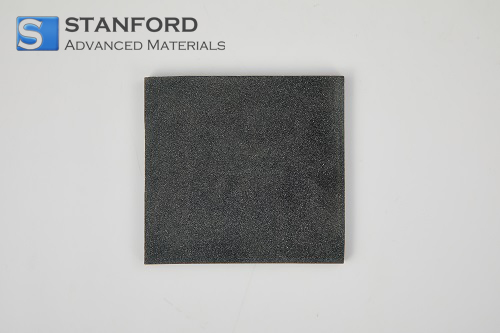

Zirconia Toughened Alumina Ceramics (ZTA composite ceramics) possess notable characteristics such as whiteness, corrosion resistance, and excellent chemical stability. Alumina provides high hardness, while zirconia contributes to good toughness. The combination of these materials forms a superior composite with high strength and toughness, enabling a wide range of applications.

ZTA ceramics exhibit higher flexural strength and fracture toughness at normal temperatures, resulting in outstanding wear resistance. The ratio of alumina to zirconia can be adjusted to meet specific user requirements. Zirconia toughened alumina ceramics outperform 99% alumina ceramics in terms of performance while being more cost-effective compared to pure zirconia ceramics.

This makes ZTA ceramics an excellent choice when alumina ceramics are not suitable for a given application, offering improved cost performance and maintaining desirable mechanical properties.

Specification of ZTA Tube

| |

Condition

|

Unit

|

ZTA Substrate

|

|

ZTA

|

|

Material

|

-

|

-

|

Al2O3/ZrO2

|

|

Color

|

-

|

-

|

White

|

|

Bulk Density

|

-

|

g/cm3

|

4

|

|

Surface Roughness Ra

|

-

|

µm

|

0.2

|

|

Reflectivity

|

0.3-0.4mmt

|

%

|

80

|

|

0.8-1.0mmt

|

90

|

|

Mechanical

|

Bending Strength

|

3-point method

|

MPa

|

700

|

|

Modulus of Elasticity

|

-

|

GPa

|

310

|

|

Vickers Hardness

|

-

|

GPa

|

15

|

|

Fracture Toughness

|

IF method

|

MPa・m1/2

|

3.5

|

|

Thermal

|

Coefficient of Thermal Expansion

|

40-400°C

|

10-6/K

|

7.1

|

|

40-800°C

|

8

|

|

Thermal Conductivity

|

25°C

|

W/(m・K)

|

27

|

|

300°C

|

16

|

|

Specific Heat

|

25°C

|

J/(kg・K)

|

720

|

|

Electrical

|

Dielectric Constant

|

1MHz

|

-

|

10.2

|

|

Dielectric Loss Factor

|

1MHz

|

10-3

|

0.2

|

|

Volume Resistivity

|

25°C

|

Ω・cm

|

>1014

|

|

Breakdown Strength

|

DC

|

kV/mm

|

>15

|

Performance of Al2O3, ZTA, and YTZ

|

Item

|

Unit

|

Alumina(AL2O3)

|

Zirconia(ZrO2)

|

|

AL2O3≥95

|

AL2O3≥99

|

AL2O3≥99.5

|

AL2O3≥99.8

|

ZTA

|

YTZ

|

|

Bulk Density

|

g/cm3

|

3.7

|

3.80~3.85

|

3.85

|

3.9

|

3.8~4.6

|

6

|

|

Hardness

|

HRA≥

|

86

|

88

|

88

|

88

|

86~88

|

88~90

|

|

Bending Strength

|

Mpa≥

|

300

|

350

|

400

|

400

|

172~450

|

900

|

|

Maximum Service Temperature

|

℃

|

1500

|

1500

|

1500

|

1500

|

1400~1500

|

1500

|

|

Linear Expansion Coefficient

|

×10-6/℃

|

7.5

|

8.2

|

8.2

|

8.2

|

|

|

|

Dielectric Constant

|

εr(20℃,1MHz)

|

9

|

9.2

|

9.2

|

9.2

|

|

|

|

Dielectric Loss

|

tanδ×10-4,1MHz

|

3

|

2

|

2

|

2

|

|

|

|

Volume Resistivity

|

Ω·cm(20℃)

|

1013

|

1014

|

1014

|

1014

|

1013

|

1014

|

|

Breakdown Strength

|

KV/mm, DC≥

|

20

|

20

|

20

|

20

|

|

|

|

Acid Resistance

|

mg/cm2≤

|

0.7

|

0.7

|

0.7

|

0.7

|

|

|

|

Alkali Resistance

|

mg/cm2≤

|

0.2

|

0.1

|

0.1

|

0.1

|

|

|

|

Wear Resistance

|

g/cm2≤

|

0.2

|

0.1

|

0.1

|

0.1

|

|

|

|

The Compressive Strength

|

Mpa≥

|

2500

|

2500

|

2500

|

2800

|

2300~2900

|

2500

|

|

Flexural Strength

|

Mpa≥

|

200

|

350

|

350

|

350

|

|

|

|

Modulus of Elasticity

|

Gpa

|

300

|

350

|

350

|

350

|

|

|

|

Poisson's Ratio

|

|

0.2

|

0.22

|

0.22

|

0.22

|

|

|

|

Coefficient of Thermal Conductivity

|

W/m·K(20℃)

|

20

|

25

|

25

|

25

|

|

|

Applications of ZTA Tube

In mechanical engineering, ZTA tubes are used for high-wear components like pump seals, bearings, and shafts, as well as in thermal and electrical insulating applications due to their high dielectric strength and thermal stability.

Chemical processing industries utilize ZTA for corrosion-resistant linings in reactors and as seals and gaskets in harsh chemical environments, benefiting from their inertness and durability.

In medical and biotechnology fields, ZTA tubes serve as laboratory equipment and implantable devices for their biocompatibility and strength, while in the electronics sector, they act as high-temperature insulators and semiconductor manufacturing components.

Within the energy sector, ZTA provides thermal barrier properties in gas turbines and heat exchangers, withstanding high temperatures and thermal cycling.

Aerospace and automotive applications rely on ZTA for engine components needing high mechanical strength, thermal stability, and wear resistance. Even in environmental and analytical instruments, ZTA tubes are used in gas analysis and environmental monitoring instruments for their stability and resistance to harsh gases.

Packaging of ZTA Tube

Our ZTA Tube is clearly tagged and labeled externally to ensure efficient identification and quality control. The products are separated by foam for shockproof purposes and finally packed in wooden or carton boxes. Great care is taken to avoid any damage which might be caused during storage or transportation.

Frequently Asked Questions (FAQ)

- Can ZTA Tubes be customized for specific applications?

Yes, ZTA Tubes can be customized in terms of composition, microstructure, dimensions, tolerances, surface finish, and other properties to meet the specific requirements of different applications.

- Are ZTA Tubes suitable for high-temperature applications?

Yes, ZTA Tubes exhibit excellent thermal stability and can withstand high temperatures, making them suitable for use in environments with elevated operating temperatures such as furnaces, kilns, and reactors.

- How do you handle and install ZTA Tubes?

ZTA Tubes should be handled with care to prevent damage, particularly during transportation, storage, and installation. Proper cleaning and inspection procedures should be followed to ensure optimal performance.

English

English Española

Española Deutsch

Deutsch Français

Français Italiano

Italiano