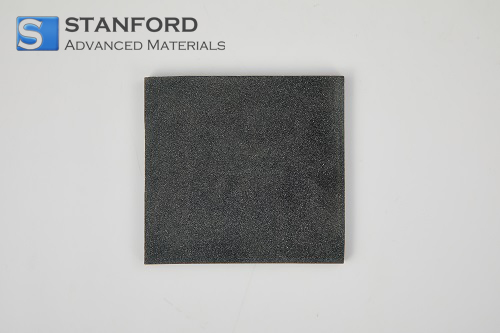

Description of ZTA Sheet/Plate

Zirconia Toughened Alumina Ceramics (ZTA composite ceramics) possess notable characteristics such as whiteness, corrosion resistance, and excellent chemical stability. Alumina provides high hardness, while zirconia contributes to good toughness. The combination of these materials forms a superior composite with high strength and toughness, enabling a wide range of applications.

ZTA ceramics exhibit higher flexural strength and fracture toughness at normal temperatures, resulting in outstanding wear resistance. The ratio of alumina to zirconia can be adjusted to meet specific user requirements. Zirconia toughened alumina ceramics outperform 99% alumina ceramics in terms of performance while being more cost-effective compared to pure zirconia ceramics.

This makes ZTA ceramics an excellent choice when alumina ceramics are not suitable for a given application, offering improved cost performance and maintaining desirable mechanical properties.

Specification of ZTA Sheet/Plate

| |

Condition

|

Unit

|

ZTA Substrate

|

|

ZTA

|

|

Material

|

-

|

-

|

Al2O3/ZrO2

|

|

Color

|

-

|

-

|

White

|

|

Bulk Density

|

-

|

g/cm3

|

4

|

|

Surface Roughness Ra

|

-

|

µm

|

0.2

|

|

Reflectivity

|

0.3-0.4mmt

|

%

|

80

|

|

0.8-1.0mmt

|

90

|

|

Mechanical

|

Bending Strength

|

3-point method

|

MPa

|

700

|

|

Modulus of Elasticity

|

-

|

GPa

|

310

|

|

Vickers Hardness

|

-

|

GPa

|

15

|

|

Fracture Toughness

|

IF method

|

MPa・m1/2

|

3.5

|

|

Thermal

|

Coefficient of Thermal Expansion

|

40-400°C

|

10-6/K

|

7.1

|

|

40-800°C

|

8

|

|

Thermal Conductivity

|

25°C

|

W/(m・K)

|

27

|

|

300°C

|

16

|

|

Specific Heat

|

25°C

|

J/(kg・K)

|

720

|

|

Electrical

|

Dielectric Constant

|

1MHz

|

-

|

10.2

|

|

Dielectric Loss Factor

|

1MHz

|

10-3

|

0.2

|

|

Volume Resistivity

|

25°C

|

Ω・cm

|

>1014

|

|

Breakdown Strength

|

DC

|

kV/mm

|

>15

|

Performance of Al2O3, ZTA, and YTZ

|

Item

|

Unit

|

Alumina(AL2O3)

|

Zirconia(ZrO2)

|

|

AL2O3≥95

|

AL2O3≥99

|

AL2O3≥99.5

|

AL2O3≥99.8

|

ZTA

|

YTZ

|

|

Bulk Density

|

g/cm3

|

3.7

|

3.80~3.85

|

3.85

|

3.9

|

3.8~4.6

|

6

|

|

Hardness

|

HRA≥

|

86

|

88

|

88

|

88

|

86~88

|

88~90

|

|

Bending Strength

|

Mpa≥

|

300

|

350

|

400

|

400

|

172~450

|

900

|

|

Maximum Service Temperature

|

℃

|

1500

|

1500

|

1500

|

1500

|

1400~1500

|

1500

|

|

Linear Expansion Coefficient

|

×10-6/℃

|

7.5

|

8.2

|

8.2

|

8.2

|

|

|

|

Dielectric Constant

|

εr(20℃,1MHz)

|

9

|

9.2

|

9.2

|

9.2

|

|

|

|

Dielectric Loss

|

tanδ×10-4,1MHz

|

3

|

2

|

2

|

2

|

|

|

|

Volume Resistivity

|

Ω·cm(20℃)

|

1013

|

1014

|

1014

|

1014

|

1013

|

1014

|

|

Breakdown Strength

|

KV/mm, DC≥

|

20

|

20

|

20

|

20

|

|

|

|

Acid Resistance

|

mg/cm2≤

|

0.7

|

0.7

|

0.7

|

0.7

|

|

|

|

Alkali Resistance

|

mg/cm2≤

|

0.2

|

0.1

|

0.1

|

0.1

|

|

|

|

Wear Resistance

|

g/cm2≤

|

0.2

|

0.1

|

0.1

|

0.1

|

|

|

|

The Compressive Strength

|

Mpa≥

|

2500

|

2500

|

2500

|

2800

|

2300~2900

|

2500

|

|

Flexural Strength

|

Mpa≥

|

200

|

350

|

350

|

350

|

|

|

|

Modulus of Elasticity

|

Gpa

|

300

|

350

|

350

|

350

|

|

|

|

Poisson's Ratio

|

|

0.2

|

0.22

|

0.22

|

0.22

|

|

|

|

Coefficient of Thermal Conductivity

|

W/m·K(20℃)

|

20

|

25

|

25

|

25

|

|

|

Applications of ZTA Sheet/Plate

1. Wear-Resistant Linings: ZTA ceramic sheets and plates are used as wear-resistant linings in industrial equipment, such as chutes, hoppers, and conveyors, to protect against abrasion and extend the lifespan of the equipment.

2. Cutting and Grinding Tools: Utilized in the manufacturing of cutting and grinding tools where high hardness and wear resistance are critical for maintaining sharp edges and reducing tool wear.

3. Heat Shields and Thermal Insulators: Employed as heat shields and thermal insulators in high-temperature environments, such as furnaces, kilns, and heat treatment equipment, due to their excellent thermal stability and resistance to thermal shock.

4. Biomedical Implants: Used in biomedical applications, such as dental implants and orthopedic implants, where biocompatibility, mechanical strength, and wear resistance are essential.

5. Electronic Substrates: Applied in the electronics industry as substrates for electronic components and circuits, benefiting from their electrical insulation properties and ability to withstand high temperatures.

6. Aerospace and Defense: Utilized in aerospace and defense applications for protective armor, structural components, and thermal barriers, taking advantage of their high strength-to-weight ratio and resistance to extreme conditions.

7. Chemical Processing Equipment: Used in chemical processing equipment where resistance to corrosion, wear, and high temperatures is necessary to ensure reliability and longevity.

8. Ballistic Armor: Incorporated in ballistic armor for personal protection and vehicle armor, providing superior impact resistance and durability against ballistic threats.

9. Precision Engineering Components: Employed in precision engineering applications, such as gauges, fixtures, and jigs, where high dimensional stability and wear resistance are required.

10. Renewable Energy: Used in renewable energy applications, such as wind turbines and solar panels, where durable and weather-resistant materials are needed to ensure long-term performance.

11. Mining and Mineral Processing: Applied in mining and mineral processing equipment for components that must endure harsh and abrasive conditions, such as grinding mills and crushers.

12. Food and Beverage Industry: Utilized in the food and beverage industry for equipment components that require chemical inertness, wear resistance, and easy cleaning to maintain hygiene standards.

Packaging of ZTA Sheet/Plate

Our ZTA Sheet/Plate is clearly tagged and labeled externally to ensure efficient identification and quality control. The products are wrapped in plastic foam for shockproof purposes and finally packed in wooden boxes. Great care is taken to avoid any damage which might be caused during storage or transportation.

English

English Española

Española Deutsch

Deutsch Français

Français Italiano

Italiano