- Products

- Categories

- Blog

- Podcast

- Application

- Document

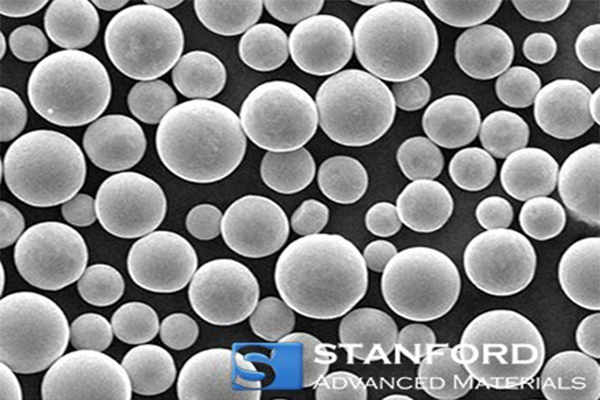

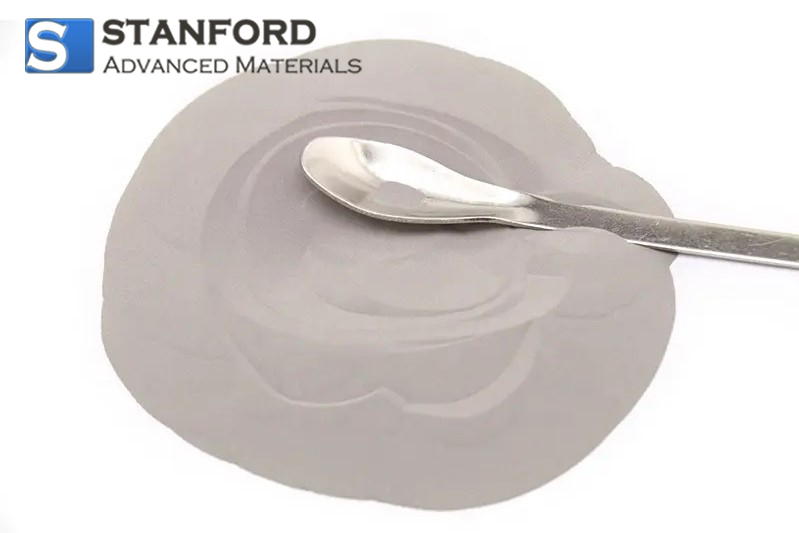

DP4538 C103 Spherical Powder (Niobium Hafnium)

| Catalog No. | DP4538 |

| Compositions | Nb, Hf |

| Shape | Spherical Powder |

| Size | 15-53μm, 53-180μm |

C103 Spherical Powder is offered in spherical powder for use with the electron beam. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality C103 Spherical Powder.

Related products: Spherical Copper Powder, Spherical Titanium Powder, Spherical Nickel Powder

INQUIRY

Add to Inquiry List

Description

Specification

Technical Data Sheet

LATEST RECOMMENDED

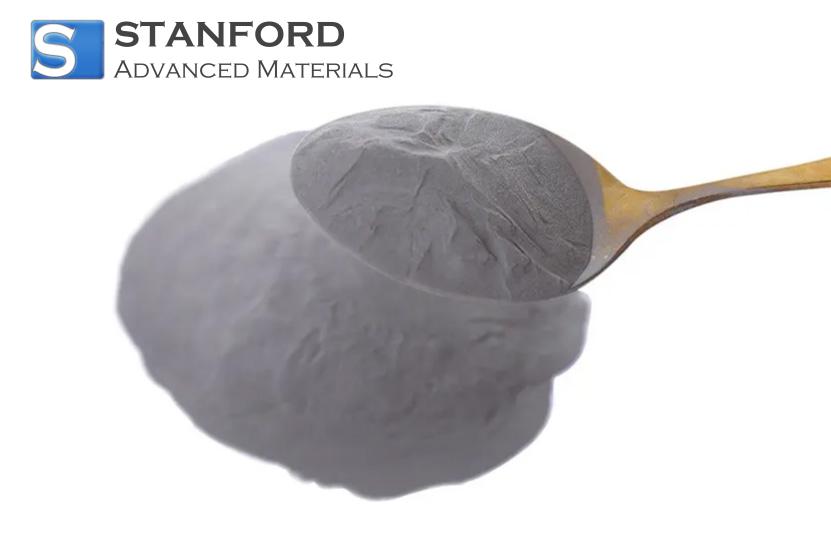

DP1233 Spherical Titanium Powder for 3D Printing

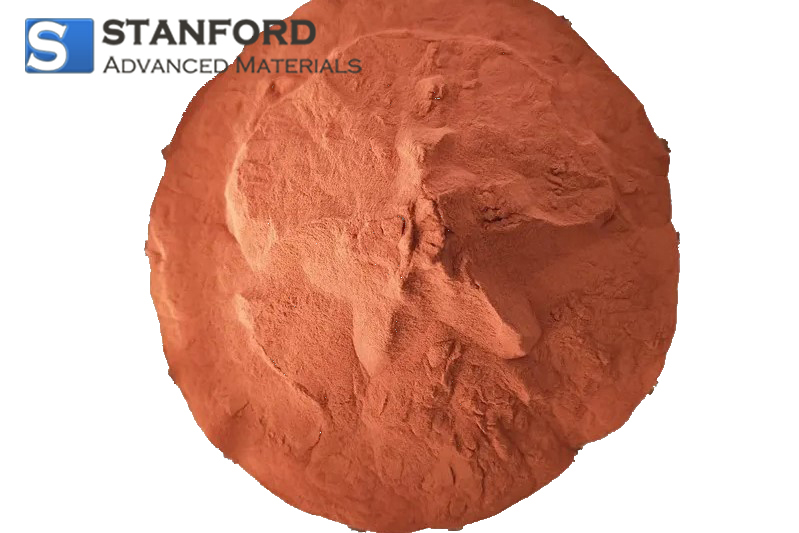

CM1308 Spherical Copper Powder (3D Printing Material)

DP1309 Spherical Nickel Powder for 3D Printing

NB1310 Spherical Niobium Powder (Spherical Nb Powder)

TA1322 Spherical Tantalum Powder (Ta)

NC1323 Spherical Inconel 600 (UNS N06600) Powder (3D Printing Additive)

Powder.jpg)

NC1324 Spherical Inconel 718 (UNS N07718) Powder (3D Printing Material)

DP1325 Spherical Hastelloy X Powder (UNS N06002) for 3D Printing

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!