Ductile-to-Brittle Transition Temperature

Description of Ductile-to-Brittle Transition

Ductile-to-brittle transition temperature marks the point where materials shift from ductile to brittle behavior, crucial for material selection in engineering.

Understanding Ductile-to-Brittle Transition

The ductile-to-brittle transition temperature (DBTT) is a critical property of materials, especially metals and alloys. It signifies the temperature below which a material behaves in a brittle manner, fracturing without significant plastic deformation.

Importance of DBTT in Material Science

Understanding DBTT is essential for engineers to ensure the reliability and safety of structures and components, particularly those exposed to varying temperature conditions.

Calculation of Transition Temperature

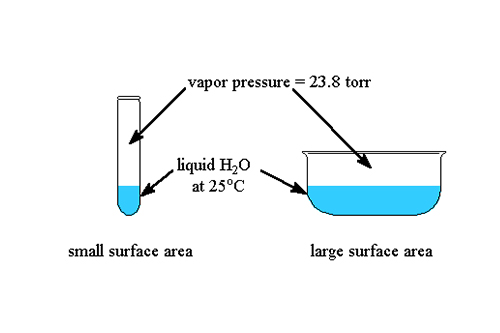

Calculating the DBTT involves analyzing the material's response to stress at different temperatures. The transition is often determined using standardized testing methods.

- Charpy Impact Test: Measures the energy absorbed by a material during fracture.

- Fracture Toughness Testing: Assesses a material's resistance to crack propagation.

- Dynamic Tear Testing: Evaluates the material's behavior under dynamic loading conditions.

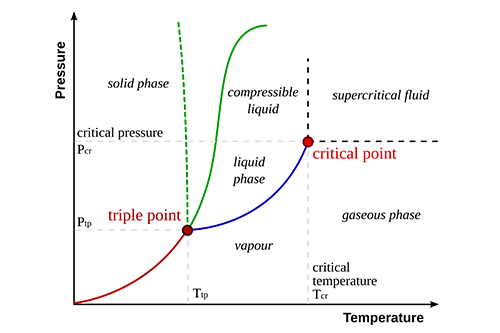

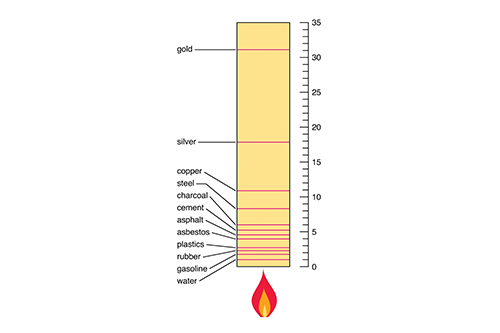

Curves Illustrating the Transition

The DBTT is typically represented using temperature-dependent fracture toughness curves, which show the relationship between temperature and the material's ability to absorb energy before fracturing.

- Transition Range: The temperature range over which the material changes from ductile to brittle behavior.

- Upper Shelf: The region where the material exhibits high toughness and ductility.

- Lower Shelf: The region where the material behaves in a brittle manner with low toughness.

Examples of Metals and Alloys

Different metals and alloys exhibit varying DBTTs based on their composition and microstructure.

Steel Alloys

- Low-Carbon Steels: Generally have lower DBTT, making them more ductile.

- High-Carbon Steels: Higher DBTT due to increased hardness and strength.

Aluminum Alloys

Aluminum alloys typically exhibit lower DBTTs, maintaining ductility over a wide temperature range, making them suitable for applications requiring lightweight and reliable materials.

Titanium Alloys

Titanium alloys have a DBTT that is influenced by alloying elements, offering a balance between strength and ductility for aerospace applications.

Ductile to Brittle Transition Temperature Table

|

Material |

Ductile to Brittle Transition Temperature (DBTT) |

|

Low-Carbon Steel (A36) |

-10°C to -40°C |

|

Medium-Carbon Steel |

-20°C to -50°C |

|

High-Carbon Steel |

-50°C to -100°C |

|

Low-Alloy Steel |

-30°C to -50°C |

|

Stainless Steel (304) |

-200°C to -300°C |

|

Stainless Steel (430) |

0°C to -50°C |

|

Nickel |

-100°C to -150°C |

|

Aluminum (Al) |

-150°C to -200°C |

|

-300°C to -400°C |

|

|

Copper (Cu) |

No clear DBTT |

|

~300°C |

|

|

-50°C to -150°C |

|

|

Polyethylene (PE) |

-70°C to -90°C |

|

Polycarbonate (PC) |

-100°C to -150°C |

|

Polytetrafluoroethylene (PTFE) |

-150°C to -200°C |

|

Polypropylene (PP) |

-10°C to -50°C |

For more information, please check Stanford Advanced Materials (SAM).

Frequently Asked Questions

What is the ductile-to-brittle transition temperature?

It's the temperature below which a material becomes brittle and fractures

without significant plastic deformation.

Why is DBTT important in engineering?

DBTT helps engineers select appropriate materials for applications subject to

varying temperatures to ensure safety and reliability.

How is DBTT measured?

DBTT is typically measured using impact tests like the Charpy or Izod tests,

which assess the energy absorbed during fracture.

Can alloying elements affect the DBTT?

Yes, adding alloying elements can either increase or decrease the DBTT,

depending on their effect on the material's microstructure.

Which metals have the lowest DBTT?

Metals like aluminum and copper alloys generally have lower DBTTs, maintaining ductility

over a wider temperature range.