Antimony Oxide (Sb₂O₃) Evaporation Materials Description

Antimony Oxide (Sb₂O₃) Evaporation Materials are meticulously crafted for precision in thin-film deposition processes. Serving as a critical component in the production of coatings with specific optical and electrical properties, these materials play a pivotal role in various technological applications.

Key Features

-

High Purity - Boasting exceptional purity, our Sb₂O₃ Evaporation Materials ensure the deposition of films free from contaminants that could compromise performance.

-

Stoichiometric Composition - The precise stoichiometric composition of antimony oxide enhances its performance, making it a reliable choice for applications demanding accuracy.

-

Uniform Deposition - Achieve uniform and controlled film deposition, thanks to the high-quality manufacturing of our Antimony Oxide Evaporation Materials.

-

Versatility - Suitable for a range of applications, from optical coatings to semiconductors, where precision and reliability are paramount.

Antimony Oxide (Sb₂O₃) Evaporation Materials Specifications

| Property |

Value |

| Chemical Formula |

Sb₂O₃ |

| Purity |

99.99% |

| Melting Point |

656°C |

| Density |

5.2 g/cm³ |

| Thermal Conductivity |

0.026 W/cm·K |

| Refractive Index (at 550nm) |

2.087 |

| Crystal Structure |

Orthorhombic |

Antimony Oxide (Sb₂O₃) Evaporation Materials Applications

-

Optical Coatings - Sb₂O₃ is utilized in the production of optical coatings, providing specific refractive indices for lenses and other optical elements.

-

Semiconductor Devices - As a thin-film material, antimony oxide finds applications in semiconductor devices, contributing to their electrical and optical properties.

-

Gas Sensors - Sb₂O₃ is employed in gas sensors where its properties aid in detecting specific gases, making it integral in environmental monitoring.

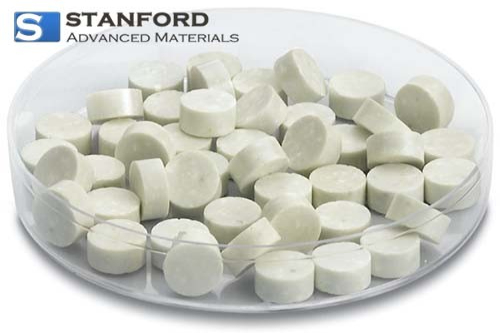

Antimony Oxide (Sb₂O₃) Evaporation Materials Packing

Our Antimony Oxide Evaporation Materials are meticulously packed to ensure their integrity during transportation and storage. The standard packing includes vacuum-sealed plastic bags within a protective outer case.

Why Choose Our Antimony Oxide (Sb₂O₃) Evaporation Materials?

-

Quality Assurance - Our materials undergo stringent quality checks to ensure they meet the highest industry standards.

-

Precision - The stoichiometric composition and purity of our Sb₂O₃ materials make them a precise choice for thin-film deposition.

-

Versatility - Whether for optical coatings or semiconductor applications, our Antimony Oxide Evaporation Materials offer versatility in performance.

For inquiries, customization, or to place an order, feel free to reach out. Elevate your thin-film deposition processes with Antimony Oxide (Sb₂O₃) Evaporation Materials.