DP3376 Aluminum Silicon Alloy Powder AlSi10Mg

| Catalog No. | DP3376 |

| Compositions | Al, Si, Mg |

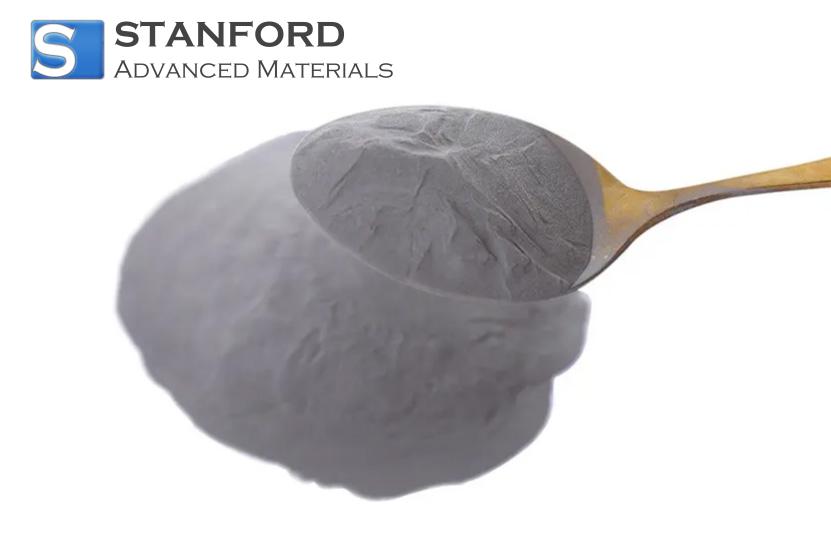

| Appearance | Gray powder |

| Particle Size | 0-45μm, 0-53μm, 15-45μm, 15-53μm, 20-63μm, 45-105μm |

Aluminum Silicon Alloy Powder AlSi10Mg has good sphericity, less satellite spheres, low oxygen content, uniform particle size distribution, and good fluidity. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Aluminum Silicon Alloy Powder AlSi10Mg.

Related products: Aluminum Silicon Alloy Powder AlSi12, Aluminum Alloy Powder 7075, Aluminum Alloy Powder 6061, Aluminum Alloy Powder 2024

Aluminum Silicon Alloy Powder AlSi10Mg Description

Aluminum Silicon Alloy Powder AlSi10Mg has good sphericity, less satellite spheres, low oxygen content, uniform particle size distribution, and good fluidity.

Aluminum Silicon Alloy Powder AlSi10Mg Specifications

|

Particle Size |

0-45μm, 0-53μm, 15-45μm, 15-53μm, 20-63μm, 45-105μm |

|||||||

|

Si |

Cu |

Ni |

Zn |

Mg |

Fe |

Mn |

Ti |

O |

|

9.0-11.0 |

≤0.05 |

≤0.05 |

≤0.10 |

0.2-0.45 |

≤0.55 |

≤0.45 |

≤0.15 |

≤0.08 |

Please Click Here for the Comparison of Alloy Silicon Powder.

Aluminum Silicon Alloy Powder AlSi10Mg Applications

Aluminum Silicon Alloy Powder AlSi10Mg can be used in various powder spreading and falling powder 3D printing equipment, such as EOS, SLM and other processes.

Aluminum Silicon Alloy Powder AlSi10Mg Packaging

Our Aluminum Silicon Alloy Powder AlSi10Mg is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

FAQs about AlSi10Mg

Q: What is AlSi10Mg used for?

A: AlSi10Mg is a widely used aluminum alloy in additive manufacturing (3D printing) and casting, particularly for aerospace, automotive, and industrial applications due to its strength, lightweight, and thermal properties.

Q: What is the difference between AlSi10Mg and 6061?

- AlSi10Mg: Contains silicon (Si) and magnesium (Mg), optimized for 3D printing and casting.

- 6061: A wrought aluminum alloy with magnesium and silicon, commonly used in machining, welding, and structural applications.

- Key difference: AlSi10Mg is better for 3D printing, while 6061 is more versatile for traditional manufacturing.

Q: What is the melting point of AlSi10Mg?

A: The melting point of AlSi10Mg is approximately 570°C (1058°F).

Q: What is the density of AlSi10Mg?

A: The density of AlSi10Mg is approximately 2.68 g/cm³. The addition of silicon and magnesium slightly increases the density compared to pure aluminum (which has a density of 2.70 g/cm³).

LATEST RECOMMENDED

Powder.jpg)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!