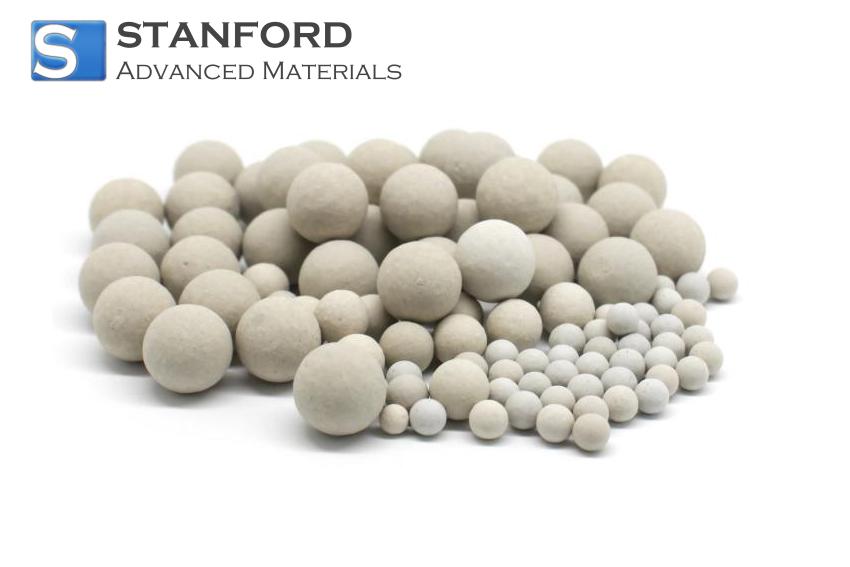

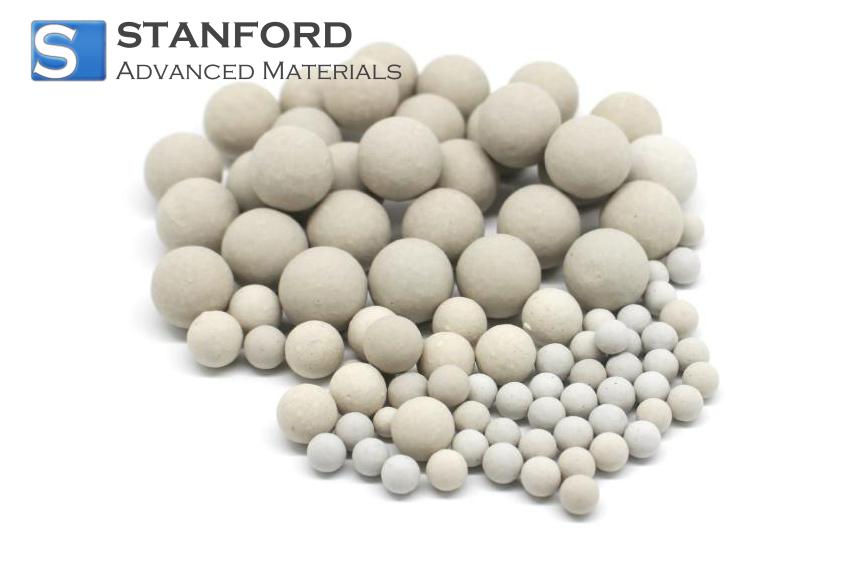

Inert Alumina Ball Description

Inert Alumina Balls, also known as Alumina Ceramic Balls, are high-purity aluminum oxide (Al₂O₃) spheres renowned for their exceptional strength, chemical stability, and thermal resistance. The term "inert" signifies that these balls do not react with other substances, ensuring that they remain chemically stable in various environments. This inertness is crucial in applications where contamination must be avoided to maintain product purity and process integrity.

.jpg)

Inert Alumina Ball Specifications

Regular Product Parameters

|

Product Name

|

SAB17

|

SAB92

|

|

Chemical Composition

%

|

Al2O3+SiO2

|

>93

|

>94

|

|

Al2O3

|

17-23

|

85-97

|

|

Fe2O3

|

<1

|

<1

|

|

CaO

|

<0.5

|

<0.5

|

|

MgO

|

<0.5

|

<0.5

|

|

K2O+Na2O

|

<4

|

<4

|

|

TiO2

|

<0.5

|

<0.1

|

|

Free Leachable Fe2O3

|

<0.1

|

<0.001

|

|

Water Absorption (%)

|

<0.5%

|

<2

|

|

Particle Density (g/cm3)

|

2.3-2.4

|

3.4

|

|

Operating Temperature (max) ℃

|

980

|

1580

|

|

Moh's Hardness

|

>6.5

|

>7.5

|

Custom Products Parameters

|

Product Name

|

SAB23

|

SAB40

|

SAB99

|

|

Chemical Composition

%

|

Al2O3+SiO2

|

>92

|

>93

|

>99

|

|

Al2O3

|

23-30

|

40-75%

|

99

|

|

Fe2O3

|

<1

|

<1

|

0.2

|

|

CaO

|

<1.5

|

<1.5

|

0.2

|

|

MgO

|

<1.5

|

<0.5

|

0.1

|

|

K2O+Na2O

|

<4

|

<3.5

|

>0.5

|

|

TiO2

|

<0.5

|

<0.1

|

0.5

|

|

Free Leachable Fe2O3

|

<0.1

|

<0.005

|

-

|

|

Water Absorption (%)

|

<0.5%

|

<1

|

2-5

|

|

Particle Density (g/cm3)

|

2.3-2.4

|

2.6-2.9

|

3.2-3.6

|

|

Operating Temperature (max) ℃

|

980

|

1450

|

1580

|

|

Moh's Hardness

|

>7

|

>7

|

>7.5

|

|

M.O.Q.

|

≥1 ton

|

Inert Alumina Ball Features

High-Purity Alumina: Our Alumina Ceramic Balls are crafted from high-purity alumina ceramics, ensuring exceptional chemical inertness and resistance to high temperatures.

Excellent Mechanical Strength: These ceramic balls exhibit remarkable mechanical strength, making them ideal for applications where durability and longevity are essential.

Low Porosity: Alumina Ceramic Balls have low porosity, which minimizes the risk of absorption and ensures their effectiveness in various processes.

Chemical Resistance: They are highly resistant to acids, bases, and a wide range of chemicals, ensuring stability in aggressive environments.

Inert Alumina Ball Benefits

Catalysis: Alumina Ceramic Balls serve as excellent catalyst support materials, offering high surface area and stability for various catalytic reactions.

Absorption: They are used in absorption processes for the removal of impurities, gases, and odors from liquids or gases.

Thermal Storage: Alumina Ceramic Balls are employed in thermal storage applications due to their ability to retain and release heat effectively.

Inert Alumina Ball Applications

Alumina Ball (Inert Ball) is widely used in petroleum, chemical fertilizer, natural gas, and environmental protection industries.

Catalysis: Alumina Ceramic Balls are widely used as catalyst support materials in various chemical processes, including petrochemical, refining, and environmental applications.

Absorption: They find application in absorption towers and columns for the removal of impurities, gases, and odors from liquids or gases in industries such as water treatment and gas purification.

Thermal Storage: These ceramic balls are employed in thermal storage systems, such as solar energy storage and high-temperature heat storage.

Inert Packing: Alumina Ceramic Balls serve as inert packing material in columns and reactors to create uniform flow distribution and support catalytic or adsorption processes.

Alumina Ceramic Ball (Inert Ball) Packaging

Our Alumina Ball is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Woven bag packaging; 25 kg/bag, Ton bag packaging: 1500 kg/bag.

Frequently Asked Questions (FAQs)

How should Inert Alumina Balls be handled and stored properly?

A: To maintain the integrity and performance of Inert Alumina Balls, please follow these handling and storage guidelines:

- Handling: Wear appropriate personal protective equipment (PPE), such as gloves and safety goggles, to prevent contamination and ensure safety.

- Storage: Store in a cool, dry place away from direct sunlight and extreme temperatures. Keep the balls in sealed containers to protect them from moisture and contamination.

- Packaging: Ensure that packaging is intact to avoid physical or chemical degradation during storage and transportation.

Are Inert Alumina Balls compatible with all types of grinding equipment?

A: Inert Alumina Balls are designed to be compatible with most standard grinding equipment, including ball mills, agitators, and tumblers. However, it is recommended to verify compatibility with your specific equipment and process requirements. For specialized applications or unique equipment, please consult our technical support team to ensure optimal performance and compatibility.

How do Inert Alumina Balls differ from standard ceramic balls?

A: Inert Alumina Balls offer several distinct advantages over standard ceramic balls:

- High Purity: Ensure no contamination in high-precision applications.

- Superior Hardness: Extend the lifespan and reduce wear and tear during grinding processes.

- Excellent Chemical Stability: Maintain performance across various chemical environments.

- High-Temperature Resistance: Suitable for processes involving elevated temperatures.

Can Alumina Balls be customized to meet specific application requirements?

A: Absolutely. Our Alumina Balls can be customized in terms of size, purity, and surface treatments to suit your unique application needs. If you have specific requirements, please reach out to our technical support or sales team to discuss the available customization options and capabilities.

Specification

Regular Product Parameters

|

Product Name

|

SAB17

|

SAB92

|

|

Chemical Composition

%

|

Al2O3+SiO2

|

>93

|

>94

|

|

Al2O3

|

17-23

|

85-97

|

|

Fe2O3

|

<1

|

<1

|

|

CaO

|

<0.5

|

<0.5

|

|

MgO

|

<0.5

|

<0.5

|

|

K2O+Na2O

|

<4

|

<4

|

|

TiO2

|

<0.5

|

<0.1

|

|

Free Leachable Fe2O3

|

<0.1

|

<0.001

|

|

Water Absorption (%)

|

<0.5%

|

<2

|

|

Particle Density (g/cm3)

|

2.3-2.4

|

3.4

|

|

Operating Temperature (max) ℃

|

980

|

1580

|

|

Moh's Hardness

|

>6.5

|

>7.5

|

Custom Products Parameters

|

Product Name

|

SAB23

|

SAB40

|

SAB99

|

|

Chemical Composition

%

|

Al2O3+SiO2

|

>92

|

>93

|

>99

|

|

Al2O3

|

23-30

|

40-75%

|

99

|

|

Fe2O3

|

<1

|

<1

|

0.2

|

|

CaO

|

<1.5

|

<1.5

|

0.2

|

|

MgO

|

<1.5

|

<0.5

|

0.1

|

|

K2O+Na2O

|

<4

|

<3.5

|

>0.5

|

|

TiO2

|

<0.5

|

<0.1

|

0.5

|

|

Free Leachable Fe2O3

|

<0.1

|

<0.005

|

-

|

|

Water Absorption (%)

|

<0.5%

|

<1

|

2-5

|

|

Particle Density (g/cm3)

|

2.3-2.4

|

2.6-2.9

|

3.2-3.6

|

|

Operating Temperature (max) ℃

|

980

|

1450

|

1580

|

|

Moh's Hardness

|

>7

|

>7

|

>7.5

|

|

M.O.Q.

|

≥1 ton

|

.jpg)