AlTi1.5Zr0.5Nb1.5Ta0.5 High Entropy Alloy Powder Description

AlTi1.5Zr0.5Nb1.5Ta0.5 High Entropy Alloy Powder is a multi-component material comprising aluminum (Al), titanium (Ti), zirconium (Zr), niobium (Nb), and tantalum (Ta). The presence of Nb and Ta enhances thermal stability, while Ti contributes excellent biocompatibility and corrosion resistance. Al provides good ductility, and Zr improves the alloy's strength, hardness, and wear resistance, thereby enhancing its durability and performance in demanding conditions. Overall, AlTi1.5Zr0.5Nb1.5Ta0.5 offers a combination of high strength, good ductility, thermal stability, and corrosion resistance.

AlTi1.5Zr0.5Nb1.5Ta0.5 High Entropy Alloy Powder Specifications

Chemical Composition

|

Element

|

Al

|

Ti

|

Zr

|

Nb

|

Ta

|

|

Content (%)

|

19.5~20.5

|

29.5~30.5

|

9.5~10.5

|

29.5~30.5

|

9.5~10.5

|

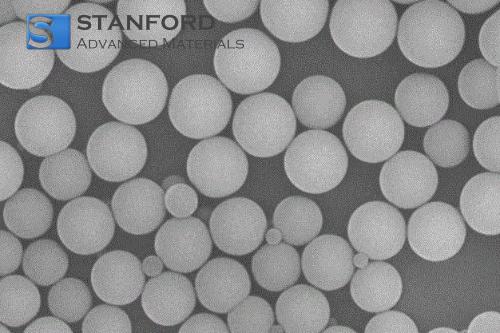

Physical Properties

|

Particle size

|

0-25μm, 15-53μm,53-150μm or Custom Made

|

|

Density

|

~6.8 g/cm3

|

|

Melting Point

|

1600~1800 ℃

|

|

Working Temperature

|

800~1100 ℃

|

AlTi1.5Zr0.5Nb1.5Ta0.5 High Entropy Alloy Powder Applications

- Aerospace: The high strength, lightweight nature, and corrosion resistance of AlTi1.5Zr0.5Nb1.5Ta0.5 High Entropy Alloy Powder make it suitable for aerospace components, including structural parts, aircraft frames, and engine components.

- Biomedical: AlTiZr0.5NbTa0.5 HEA Powder is ideal for biomedical applications, including implants, prosthetics, and surgical instruments.

- Chemical Processing: The resistance to corrosion and stability at high temperatures make AlTiZr0.5NbTa0.5 HEA Powder valuable in chemical processing equipment, reactors, and other applications involving aggressive chemicals and extreme temperatures.

- Energy Generation: AlTiZr0.5NbTa0.5 HEA Powder finds application in energy generation systems, including power plants and turbines, where high strength, thermal stability, and resistance to corrosion are critical.

- Advanced Manufacturing: AlTiZr0.5NbTa0.5 HEA Powder can be utilized in advanced manufacturing techniques such as powder metallurgy, additive manufacturing, and selective laser melting (SLM) to produce complex, high-performance components with superior mechanical properties.

AlTi1.5Zr0.5Nb1.5Ta0.5 High Entropy Alloy Powder Packaging

Our AlTi1.5Zr0.5Nb1.5Ta0.5 High Entropy Alloy Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)