- Products

- Categories

- Blog

- Podcast

- Application

- Document

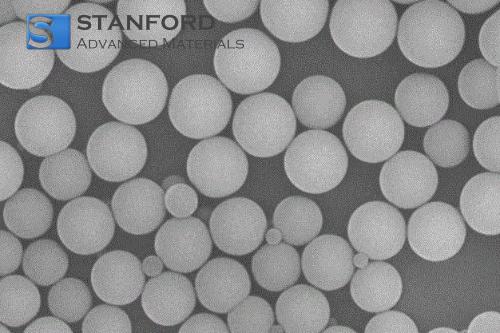

DP4984 AlCrFeNi High Entropy Alloy Powder

| Catalog No. | DP4984 |

| Compositions | Al, Cr, Fe, Ni |

| Purity | 99% |

| Appearance | Gray or black powder |

| Particle Size | 0-25um, 15-53um, 53-150um, or Custom Made |

AlCrFeNi High Entropy Alloy Powder is a fine and homogeneous powder material composed of an equimolar or near equimolar combination of aluminum (Al), chromium (Cr), iron (Fe) and nickel (Ni). Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality AlCrFeNi High Entropy Alloy Powder.

INQUIRY

Add to Inquiry List

Description

Specification

Technical Data Sheet

LATEST RECOMMENDED

FE1831 FeAlNiCrX High-Entropy Alloys Powder

.jpg)

DP3188 FeMnCoCr High-Entropy Alloy (HEA) Spherical Powder

.jpg)

DP3189 FeCrNiMnAl High-Entropy Alloy (HEA) Spherical Powder

.jpg)

DP3190 FeCoNiCrMo High-Entropy Alloy (HEA) Spherical Powder

.jpg)

DP3191 FeCoNiCrMn High-Entropy Alloy (HEA) Spherical Powder

.jpg)

DP3192 FeCoNiCrAl High-Entropy Alloy (HEA) Spherical Powder

.jpg)

DP3193 FeCoNiCr High-Entropy Alloy (HEA) Spherical Powder

.jpg)

DP3194 CuAlMnTi High-Entropy Alloy (HEA) Spherical Powder

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!