- Products

- Categories

- Blog

- Podcast

- Application

- Document

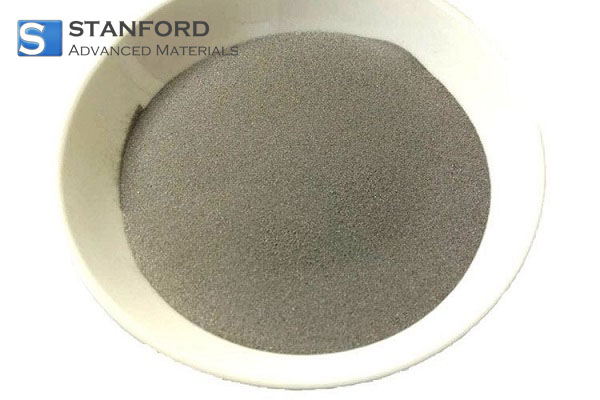

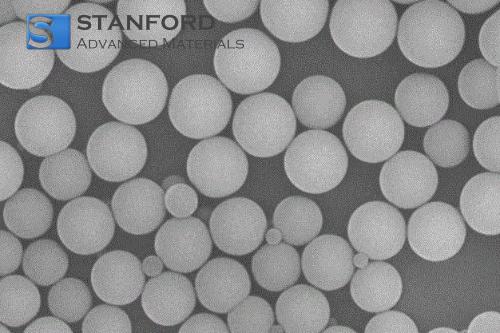

DP4975 Al0.5TiZrNbMo0.5Ta0.5 High Entropy Alloy Powder

| Catalog No. | DP4975 |

| Compositions | Al, Ti, Zr, Nb, Mo, Ta |

| Purity | 99% |

| Appearance | gray or black powder |

| Particle Size | 0-25um, 15-53um, 53-150um, or Custom Made |

Al0.5TiZrNbMo0.5Ta0.5 High Entropy Alloy Powder is a multi-component material with Aluminum (Al), Titanium (Ti), Zirconium (Zr), Niobium (Nb), Molybdenum (Mo), and Tantalum (Ta). Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Al0.5TiZrNbMo0.5Ta0.5 High Entropy Alloy Powder.

Related products: AlTiZr0.5NbMo0.5Ta0.5, AlTiZr0.5NbTa0.5, AlTi1.5Zr0.5Nb1.5Ta0.5

LATEST RECOMMENDED

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!