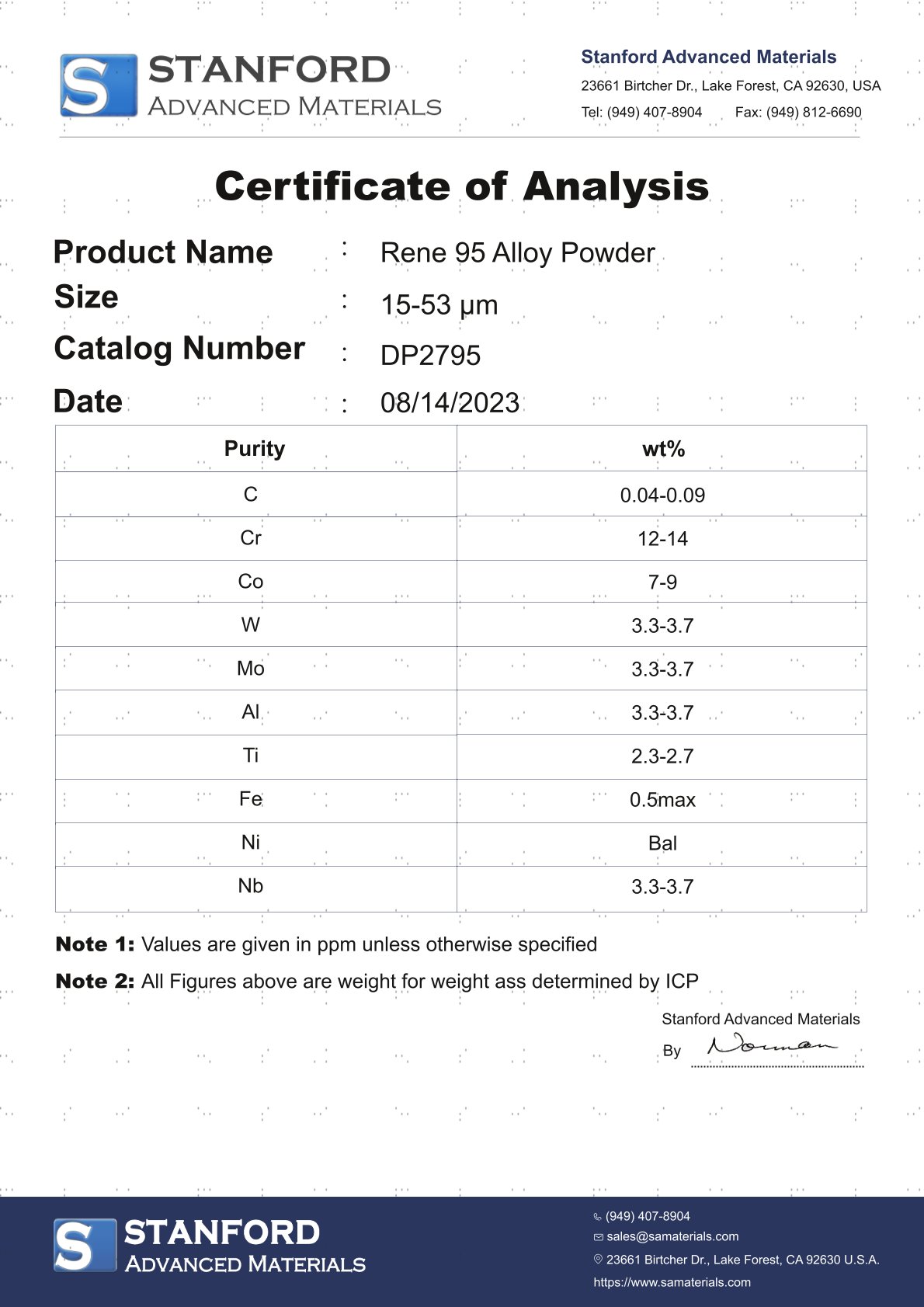

DP2795 Rene 95 Alloy Powder

| Catalog No. | DP2795 |

| Appearance | Gray metallic powder |

| Grade | Alloy Grade: FGH 4095 Related Grades: Rene 95 |

Rene 95 Alloy Powder is available at Stanford Advanced Materials (SAM). With extensive expertise in the metals industry, SAM is a global leader in manufacturing and supplying high-quality Rene 95 Alloy Powder for demanding high-performance applications.

Related Products: IN100 Alloy Powder, Inconel 713C Powder, L605 Alloy Powder, Rene 88DT Alloy Powder

Rene 95 Alloy Powder Description

Rene 95 Alloy is one of the nickel-based high-temperature, high-strength alloys that is age-hardenable by heat treatment. It is one of the strongest alloys in this alloy category that can withstand a temperature of 1400℉. Rene 95 is used in the gas turbine for hot section components.

Stanford Advanced Materials (SAM) is a global supplier of high-quality Rene 95 Alloy Powder, who has over two decades of experience in the manufacture and sale of the Rene 95 Alloy products.

Rene 95 Alloy Powder Specifications

|

Product Name |

Rene 95 Alloy Powder |

|

Alloy Grade |

FGH 4095 |

|

Related Grades |

Rene 95 |

|

Composition |

C 0.04-0.09 Nb 3.3-3.7 |

|

Size Grades |

-105+45micron -53+15micron |

|

ASTM |

/ |

|

AMS Specification |

/ |

Rene 95 Alloy Powder Applications

Cold Working

Standard tooling methods can be used for Rene 95 Alloy Powder. Soft die materials and heavy-duty lubricants are recommended during the cold working process for this alloy in order to minimize galling and obtain good results.

Welding

Rene 95 Alloy Powder can be welded by the commonly used welding techniques, and an equally corresponding alloy filler metal should be used during the welding process. The welding methods recommended for this alloy include submerged-arc welding, gas-tungsten-arc welding, gas metal-arc welding and shielded metal-arc welding.

Forming

Rene 95 Alloy Powder can be formed by the standard forming techniques. This alloy has good ductility but requires powerful equipment during the forming process because of its higher strength levels in comparison to regular steel.

Machinability

Rene 95 Alloy Powder can be machined by conventional machining methods. This alloy possesses higher strength, gumminess and work-hardening qualities while being machined. Usage of water-based coolants is preferred for milling, turning or grinding. Usage of heavy lubricants is preferred for boring, drilling, broaching or tapping operations. Work-hardening of the alloy before the cutting process and chatter can be minimized by using tooling and a heavy duty machining equipment.

Rene 95 Alloy Powder Packaging

Our Rene 95 Alloy Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Rene 95 Alloy Powder FAQs

Q1: What is Rene 95 Alloy Powder?

Rene 95 Alloy Powder is a nickel-based superalloy designed for use in extreme high-temperature environments. It contains elements such as chromium (Cr), tungsten (W), molybdenum (Mo), and cobalt (Co). This alloy is known for its excellent high-temperature strength, oxidation resistance, and creep resistance, making it ideal for use in turbine engines, gas turbines, and other demanding applications.

Q2: How is Rene 95 Alloy Powder produced?

Rene 95 Alloy Powder is produced using gas atomization or plasma atomization processes, which rapidly cool molten metal to form fine, spherical powder particles. These methods ensure high purity, consistent particle size, and optimal material properties.

Q3: What makes Rene 95 Alloy Powder different from other nickel-based alloys?

Rene 95 is known for its superior high-temperature performance, particularly its creep resistance and fatigue resistance at elevated temperatures. It is optimized for demanding applications where other nickel-based alloys might not provide the same level of performance, making it an ideal choice for turbine engines and power generation components.

LATEST RECOMMENDED

Powder.jpg)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!