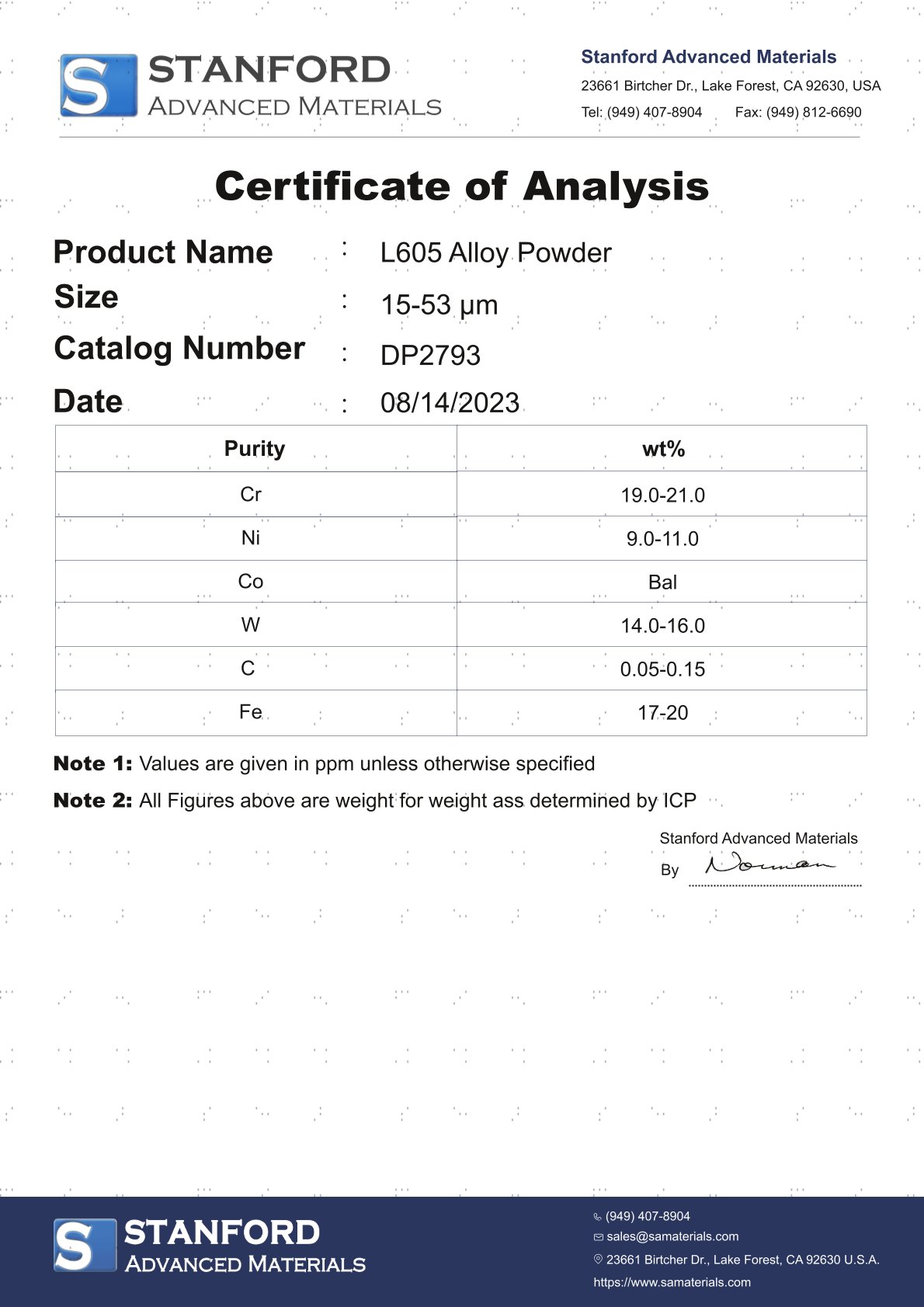

DP2793 L605 Alloy Powder (UNS R30605)

| Catalog No. | DP2793 |

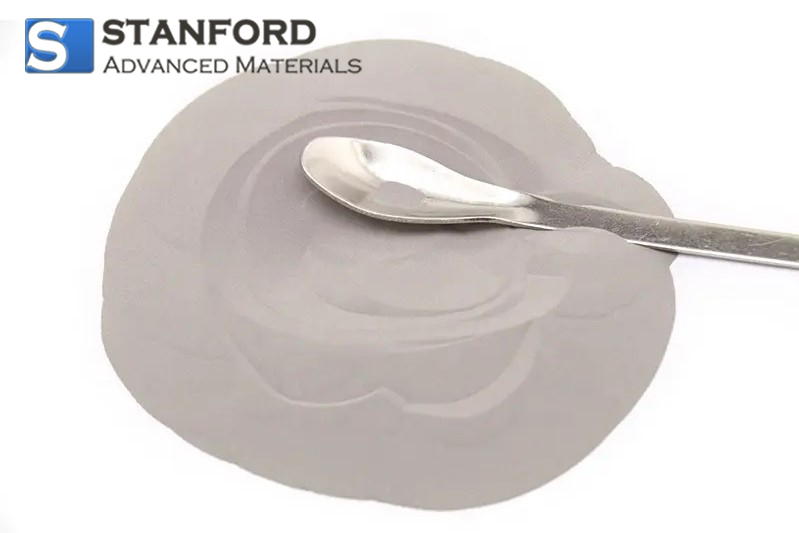

| Appearance | Gray metallic powder |

| Synonyms | Alloy 25 |

| Grade | GH605, L605 |

L605 Alloy (UNS R30605) Powder is available for purchase at Stanford Advanced Materials (SAM). With extensive expertise in the metals industry, SAM is a global leader in manufacturing and supplying high-quality L605 Alloy Powder for a variety of demanding applications.

Related Products: IN100 Alloy Powder, Inconel 713C Powder, Rene 88DT Alloy Powder, Rene 95 Alloy Powder

L605 Alloy Powder Description

L605 Alloy (UNS R30605) Powder is a non-magnetic cobalt-based superalloy. L605 Alloy maintains good strength up to 2150°F. L605 requires a minimum yield strength of 45,000 psi at room temperature. L605 maintains good oxidation resistance up to 1900° F. It has a unique ability to resist corrosion in very severe environments. Highly resistant to hydrochloric acid, nitric acid and wet chlorine, the alloy also has good sulfidation resistance and resistance to wear and galling.

L605 Alloy Powder Specifications

|

Product Name |

L605 Alloy (UNS R30605) Powder |

|

Alloy Grade |

GH605, L605 |

|

Related Grades |

/ |

|

Composition |

Cr 19.0-21.0 Mn 1 max |

|

Size Grades |

-105+45micron -53+15micron |

|

ASTM |

/ |

|

AMS Specification |

5537 |

L605 Alloy Powder Applications

L605 Alloy Powder can be used in the hot sections of aircraft and land-based gas turbines in combustor liners and other applications requiring moderate strength and good oxidation resistance at high temperatures. L605 Alloy is the strongest of the formable cobalt alloys, useful for continuous service to 1800°F. Because of long and widespread use, this alloy has been the subject of many investigations to determine its properties over a wide range of conditions, thus making it an unusually well-characterized material. The alloy can also be used in industrial furnace applications such as muffles and liners in high-temperature kilns.

L605 Alloy Powder Packaging

Our L605 Alloy Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

L605 Alloy Powder FAQs

Q1: What is L605 Alloy Powder?

L605 Alloy Powder is a cobalt-based alloy containing significant amounts of chromium (Cr), tungsten (W), and nickel (Ni). It is known for its excellent high-temperature strength, oxidation resistance, and corrosion resistance. It is commonly used in applications requiring robust performance under extreme conditions.

Q2: What industries benefit from L605 Alloy Powder?

Aerospace: For the production of high-performance turbine components, including blades and discs.

Chemical: In environments that require resistance to high temperature, oxidation, and corrosion, such as in chemical reactors and valves.

Medical: Used in surgical instruments and implants that require biocompatibility and corrosion resistance.

LATEST RECOMMENDED

Powder.jpg)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!