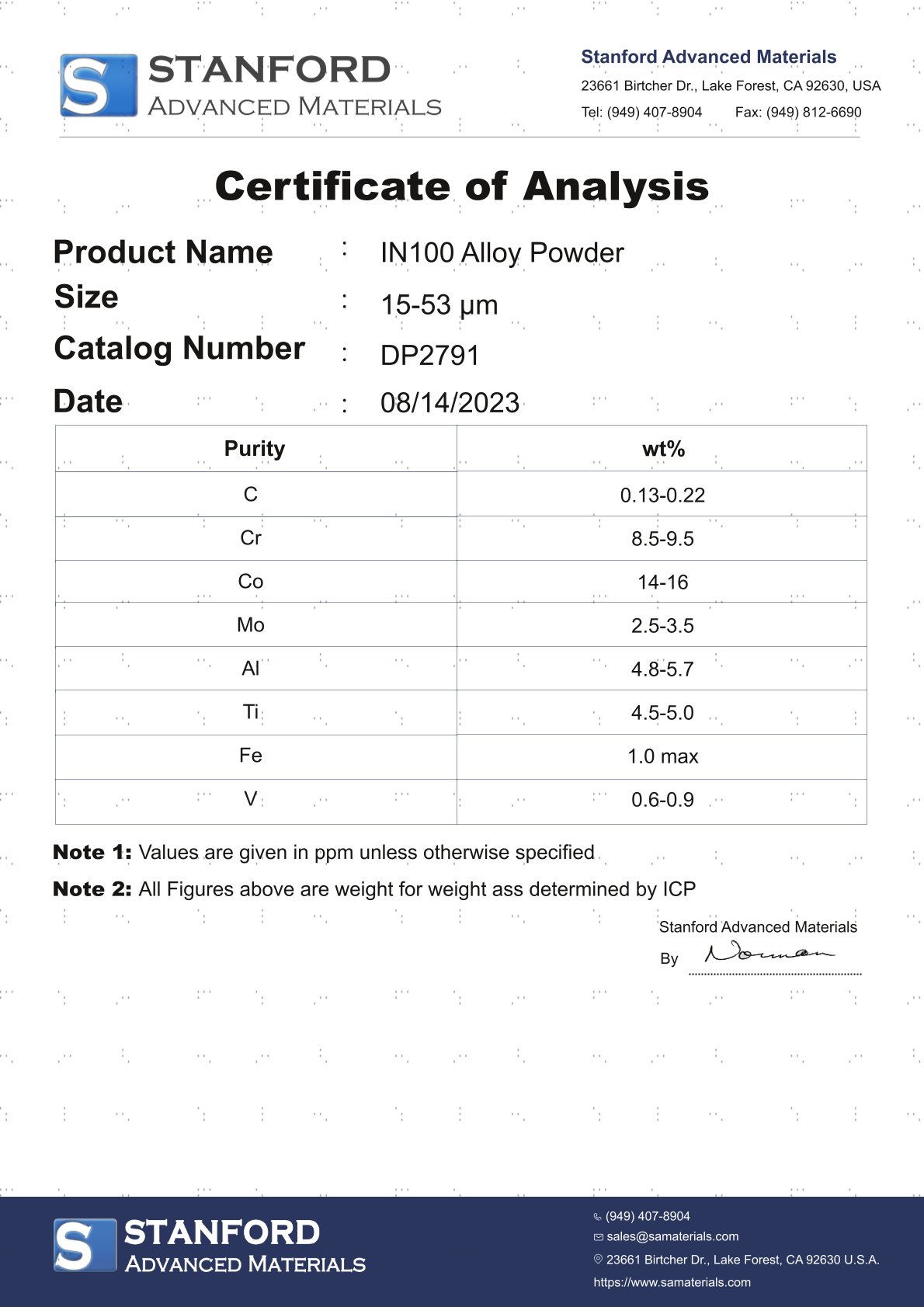

DP2791 IN100 Alloy Powder (UNS N13100)

| Catalog No. | DP2791 |

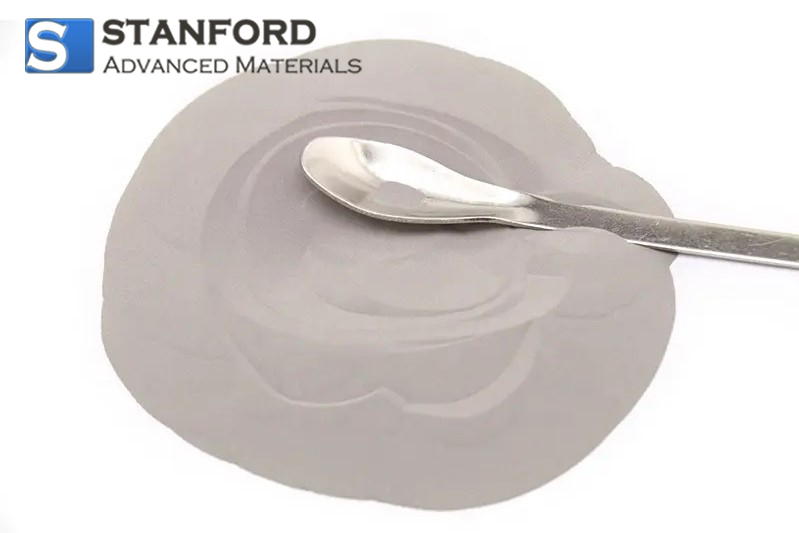

| Appearance | Gray metallic powder |

| Grade | Alloy Grade: K417(K17、M17) Related Grades: IN100 |

IN100 Alloy (UNS N13100) Powder is available for purchase at Stanford Advanced Materials (SAM). With extensive experience and expertise in the metals industry, SAM is a global supplier of high-quality IN100 Alloy Powder.

Related Products: Inconel 713C Powder, L605 Alloy Powder, Rene 88DT Alloy Powder, Rene 95 Alloy Powder

IN100 Alloy Powder Description

IN100 Alloy (UNS N13100) is a nickel-based precipitation hardenable, vacuum cast alloy possessing high rupture strength through 1900aluminum and titanium and the low refractory metal content make IN100 particularly attractive on a strength to density basis. The alloy has been successfully cast and utilized in a variety of shapes from turbine blades, vanes and nozzles to integral wheels.

Stanford Advanced Materials (SAM) has over two decades of experience in the manufacture and sale of high-quality IN100 Alloy (UNS N13100) Powder.

IN100 Alloy Powder Specification

|

Product Name |

IN100 Alloy (UNS N13100) Powder |

|

Alloy Grade |

K417(K17、M17) |

|

Related Grades |

IN100 |

|

Composition |

C 0.13-0.22 B 0.012-0.022 |

|

Size Grades |

-105+45micron -53+15micron |

|

ASTM |

/ |

|

AMS Specification |

5397 |

IN100 Alloy Powder Applications

Heat Treatment

Components made of IN100 Alloy Powder are given a protective coating to enhance corrosion resistance. This treatment generally includes a diffusion cycle at a temperature between 1800-2100 for 2-8 hours. In effect, this treatment provides the material with a partial solutioning. If the coating is to be diffused at 1900-1950, it is suggested that the material receive a preliminary high temperature solutioning at 2100-2150 An aging treatment at 1500-1600 is recommended after the coating cycle. This should provide material with a capability of maintaining a consistently high level of mechanical properties.

Machinability

Although IN100 Alloy Powder is difficult to machine as compared to carbon and stainless steels, proper use of speeds, feeds, tools and procedures will produce satisfactory results.

IN100 Alloy Powder Packaging

Our IN100 Alloy Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

IN100 Alloy Powder FAQs

Q1: What is IN100 Alloy Powder?

IN100 is a high-performance nickel-based superalloy composed primarily of nickel (Ni), with significant additions of chromium (Cr), cobalt (Co), molybdenum (Mo), titanium (Ti), and aluminum (Al). It is known for its excellent high-temperature strength, oxidation resistance, and creep resistance, making it ideal for demanding applications in the aerospace and energy sectors.

Q2: What are the key properties of IN100 Alloy Powder?

High-temperature strength: IN100 alloy retains its strength and mechanical properties at elevated temperatures, making it ideal for high-performance applications.

Oxidation and corrosion resistance: The alloy resists oxidation and corrosion, even in high-temperature environments.

Q3: What are the storage and handling requirements for IN100 Alloy Powder?

Storage: Store IN100 alloy powder in a dry, inert atmosphere to prevent oxidation or contamination. The powder should be kept in tightly sealed containers.

Handling: Use appropriate personal protective equipment (PPE) to avoid inhalation of fine powder particles. Ensure proper ventilation in working areas to minimize exposure.

LATEST RECOMMENDED

Powder.jpg)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!