- Products

- Categories

- Blog

- Podcast

- Application

- Document

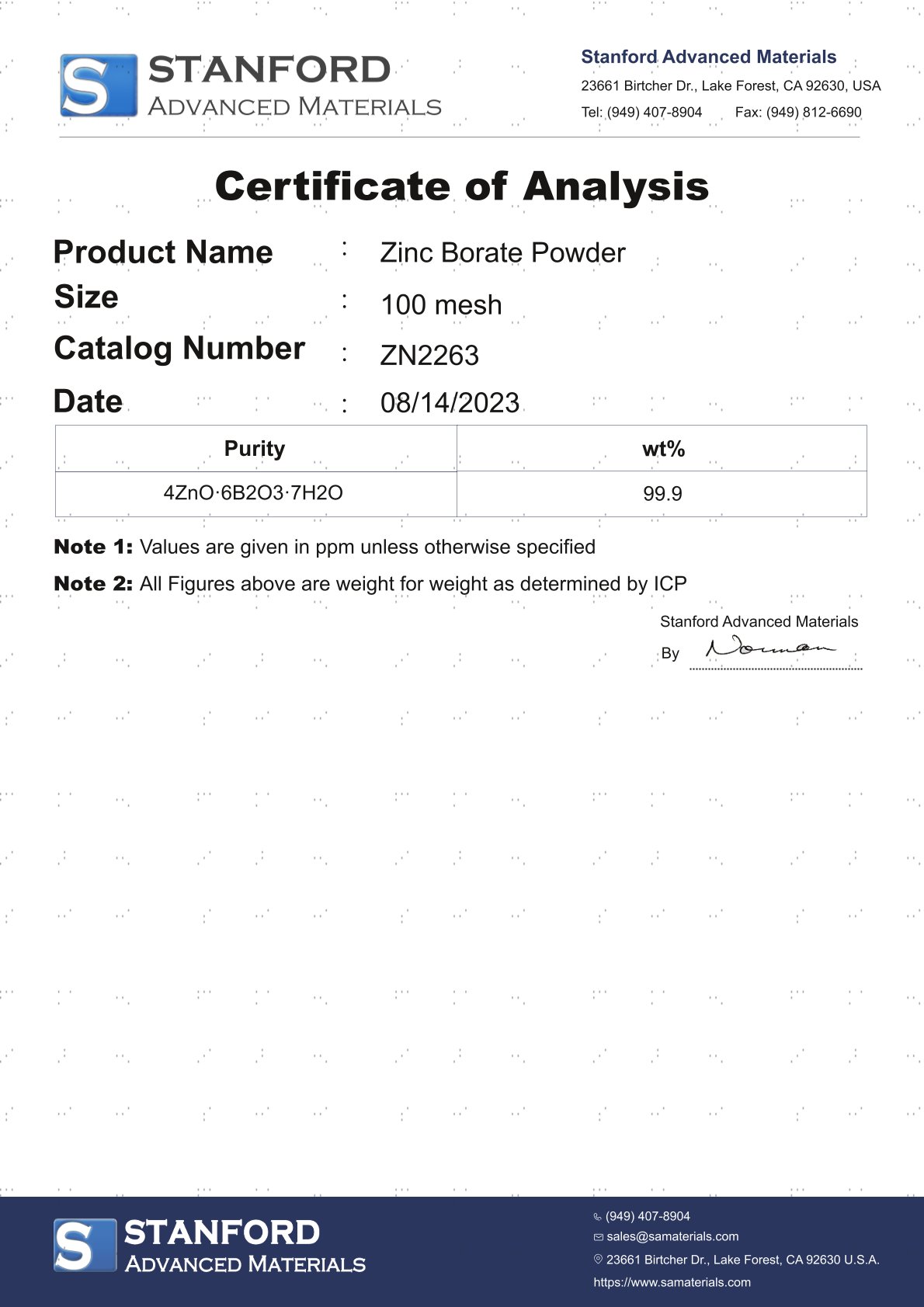

ZN2263 Zinc Borate Powder (CAS No. 12513-27-8)

| Catalog No. | ZN2263 |

| Purity | 99.9% |

| CAS Number | 12513-27-8 |

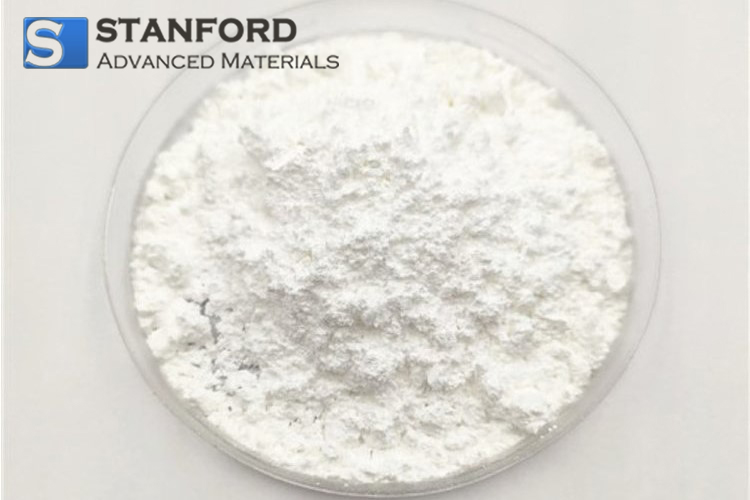

| Appearance | White powder |

| Molecular Formula | 4ZnO•6B2O3•7H2O |

| Synonyms | Boron zinc oxide (B6Zn2O11); hexaboron dizinc unde |

Stanford Advanced Materials (SAM) is a leading supplier of Zinc compounds. We provide high-quality Zinc Borate Powder in a wide range of purity. For further details, please send us your inquiry.

Related products: Zinc Stearate Powder, Zinc Hydroxide Carbonate Powder, Zinc Gluconate Powder, Zinc Molybdate Powder.

INQUIRY

Add to Inquiry List

Description

Specification

Technical Data Sheet

LATEST RECOMMENDED

NN0289 Nano Zinc Peroxide (ZnO2) (CAS No. 1314-22-3)

ZN0290 Micro Zinc Peroxide (ZnO2) (CAS No. 1314-22-3)

OX1200 Zinc Oxide Powder (ZnO Powder)

ZN1865 Zinc Sulfide (ZnS) Powder/Chunk/Lumps (CAS No.1314-98-3)

NR1900 Zinc Nitride (Zn3N2) Powder (CAS No. 1313-49-1)

ZN2025 Zinc Oxide Nanowires

TE2068 Zinc Telluride Powder (CAS No.1315-11-3)

SE2069 Zinc Selenide Lump (ZnSe Lump) (CAS No. 1315-09-9)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

GHS09

GHS09