Tungsten Alloy Rod & Tungsten Alloy Bar Description

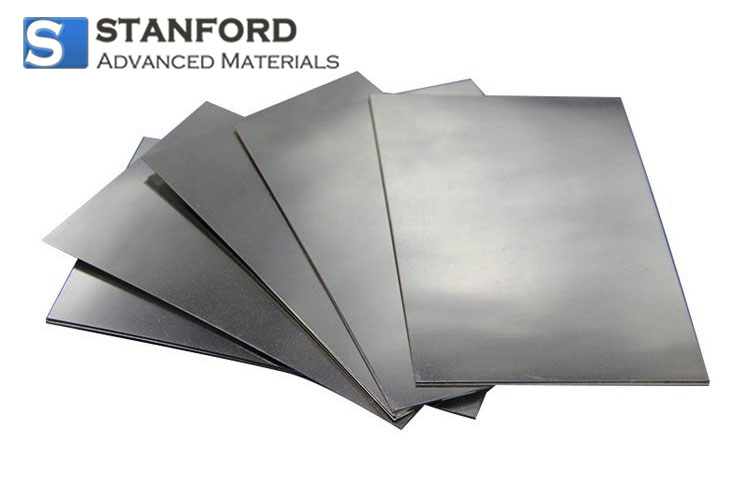

Tungsten alloy rods & tungsten alloy bars have many excellent properties such as high density, high melting point, small volume, high wear resistance, extremely high hardness, high tensile strength, high elongation, and high-temperature resistance. Tungsten alloy products are widely used in industrial fields.

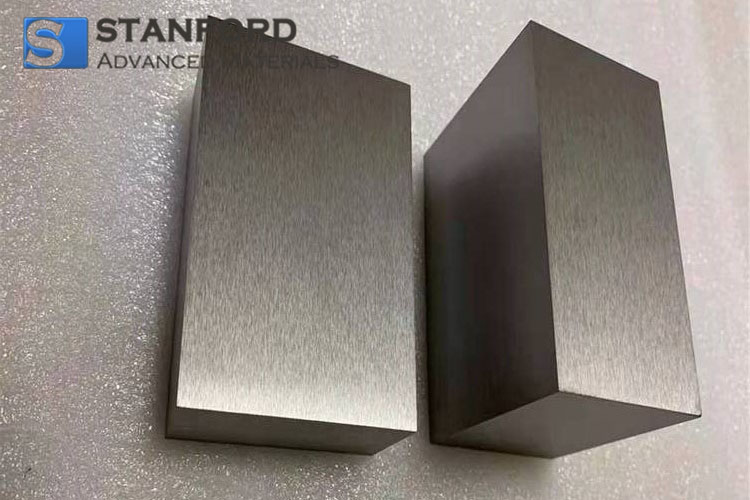

The tungsten alloy rod is prepared by first mixing tungsten powder with other metal powder, pressing it, and then sintering it into a blank semi-finished product. After the blank semi-finished product is subjected to swaging and cutting, the tungsten alloy rod is finally formed. These tungsten alloy rods can be made to any length according to customer requirements, the surface is smooth, and the diameter is more than 3mm. The hollow tube wall is within 3 mm. The tungsten alloy rod can be processed into a hollow shape. The special length and structure can be processed according to the customer's needs.

Tungsten Alloy Rod & Tungsten Alloy Bar Specification

|

Type

|

Density g/cm3

|

Tensile strength

|

Elongation

|

HRC

|

|

85W-10.5Ni-4.5Fe

|

15.8-16.0

|

700-1000

|

20-33

|

20-30

|

|

90W-7Ni-3Fe

|

16.9-17.1

|

700-1000

|

20-33

|

24-32

|

|

90W-6Ni-4Fe

|

16.7-17.0

|

700-1000

|

20-33

|

24-32

|

|

91W-6Ni-3Fe

|

17.1-17.3

|

700-1000

|

15-28

|

25-30

|

|

92W-5Ni-3Fe

|

17.3-17.5

|

700-1000

|

18-28

|

25-30

|

|

92.5W-5Ni-2.5Fe

|

17.4-17.6

|

700-1000

|

25-30

|

25-30

|

|

93W-4Ni-3Fe

|

17.5-17.6

|

700-1000

|

15-25

|

26-30

|

|

93W-4.9Ni-2.1Fe

|

17.5-17.6

|

700-1000

|

15-25

|

26-30

|

|

93W-5Ni-2Fe

|

17.5-17.6

|

700-1000

|

15-25

|

26-30

|

|

95W-3Ni-2Fe

|

17.9-18.1

|

700-900

|

8-15

|

25-35

|

|

95W-3.5Ni-1.5Fe

|

17.9-18.1

|

700-900

|

8-15

|

25-35

|

|

96W-3Ni-1Fe

|

18.2-18.3

|

600-800

|

6-10

|

30-35

|

|

97W-2Ni-1Fe

|

18.4-18.5

|

600-800

|

8-14

|

30-35

|

|

98W-1Ni-1Fe

|

18.4-18.6

|

500-800

|

5-10

|

30-35

|

|

90W-6Ni-4Cu

|

>17.0-17.2

|

600-800

|

4-8

|

25-35

|

|

93W-5Ni-2Cu

|

17.5-17.6

|

500-600

|

3-5

|

25-35

|

Tungsten Alloy Rod & Tungsten Alloy Bar Application

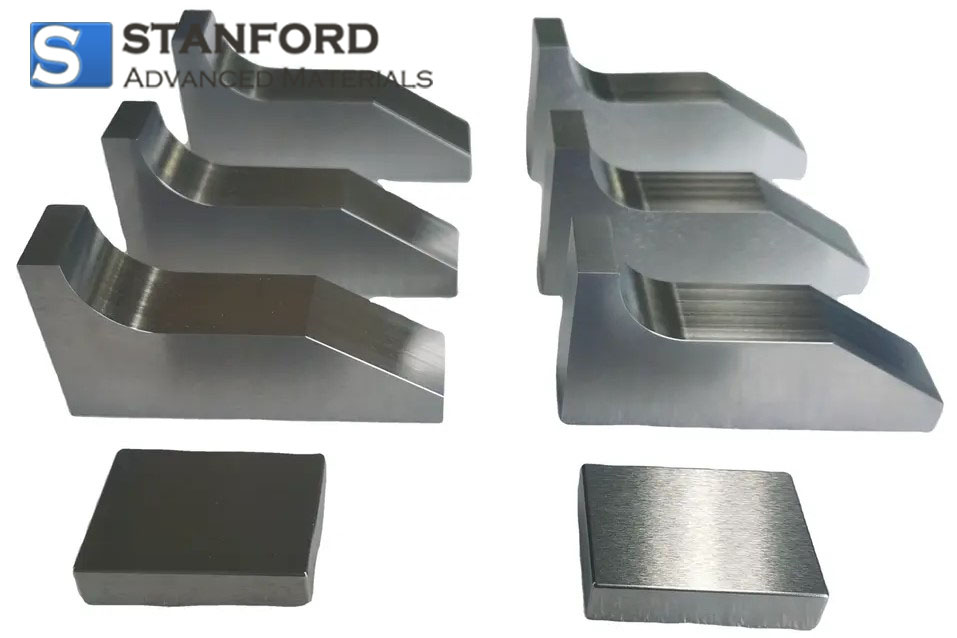

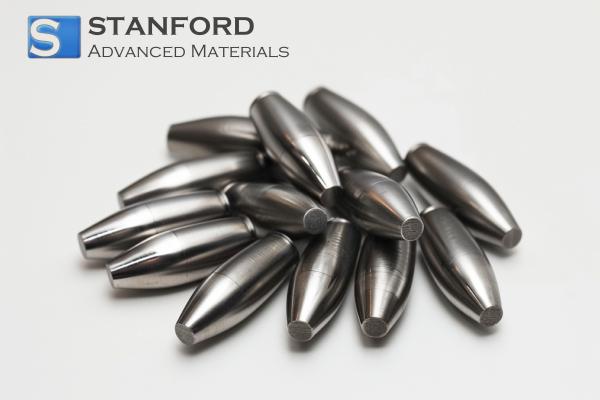

Due to their high density, the main use of tungsten alloy rods is as a weighting member for controlling and distributing weight. The tungsten alloy rod can be further processed into a weight member. Tungsten alloy rods supplied by SAM can be used for weight parts, radiation shields, military products, welding rods, molds, etc. Some sporting goods also use tungsten alloy rods, such as darts, golf clubs and so on. Other uses include vacuum electronics, and can also be used as high-temperature resistant parts.

Tungsten Alloy Rod/Bar Packing

Our Tungsten Alloy Rod/Bar is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Related articles:

Why Do We Need High-density Tungsten Alloy Shielding?

How Are Tungsten Alloys Used in the Aerospace Industry?

Military Tungsten Alloy Counterweight