- Products

- Categories

- Blog

- Podcast

- Application

- Document

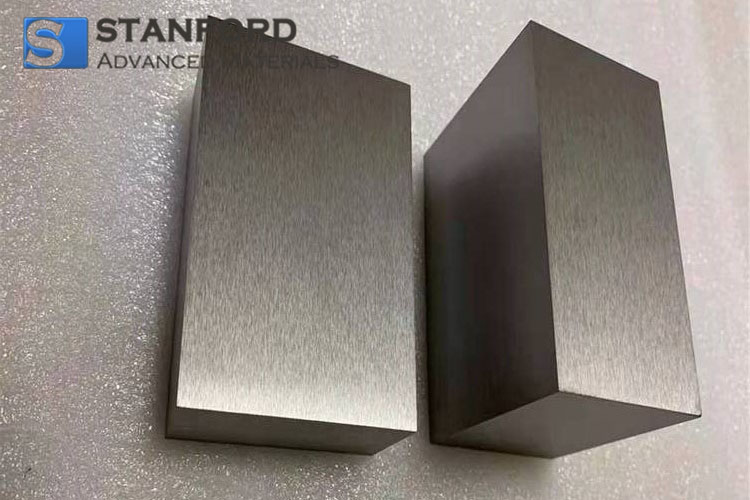

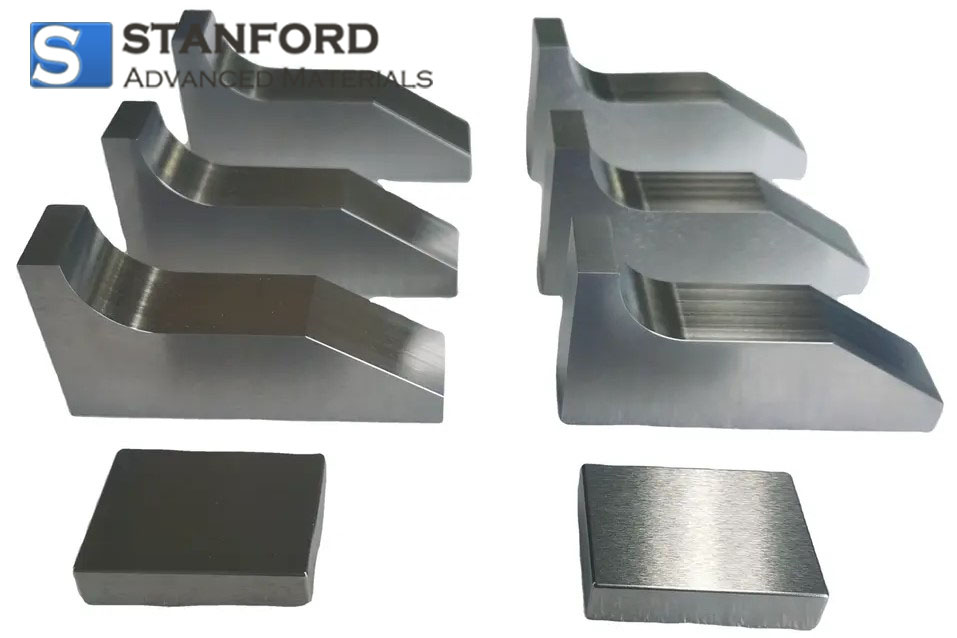

WM4857 Tungsten Copper Bar

| Catalog No. | WM4857 |

| Material | Tungsten, Copper |

| Density | 12.75-15.0 (g/cm3) |

| Diameter | 0.125” to 20” |

| Shape | Bar |

Tungsten Copper Bar is a pseudo-alloy of copper and tungsten. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Tungsten Copper Bar.

Related products: Tungsten-Copper (W-Cu) Electrodes, Tungsten Copper Composite, Tungsten Copper Plate

INQUIRY

Add to Inquiry List

Description

Specification

LATEST RECOMMENDED

WM0125 Tungsten Nickel Iron Alloy (W-Ni-Fe Alloy)

WM0126 Tungsten Nickel Copper Alloy (W-Ni-Cu Alloy)

WM0128 Tungsten Alloy Counterweight Parts

WM0132 Tungsten Bucking Bar (W Bucking Bar)

WM0133 Tungsten Alloy Boring Bar & Tungsten Alloy Grinding Quill

WM0134 Tungsten Penetrator (W Penetrator)

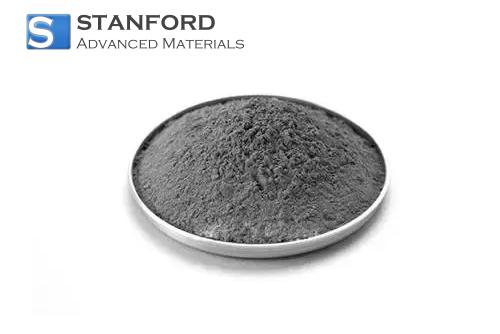

WM4457 (Discontinued) Spherical Copper-coated Tungsten (W-Cu) Powder

WM4458 (Discontinued) Spherical Nickel-coated Tungsten Powder

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!