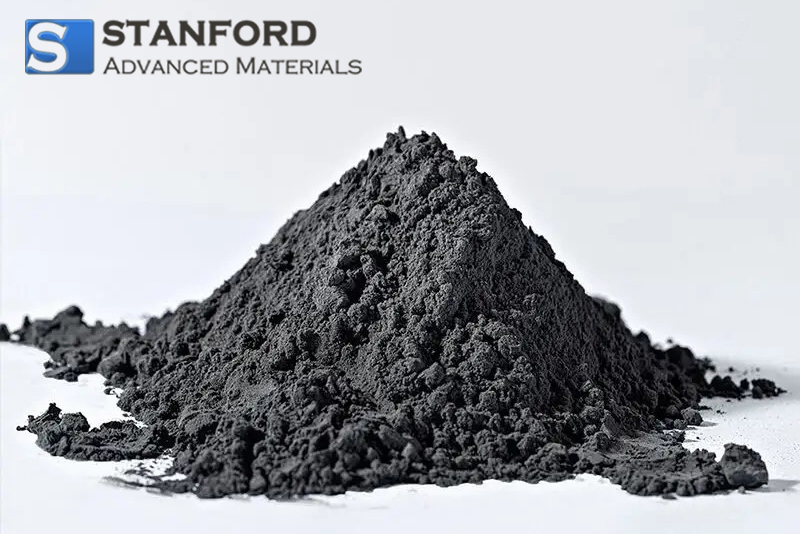

Tungsten Carbide Cobalt Powder (WC-12Co) Description

Tungsten Carbide Cobalt Powder (WC-12Co) is a high-performance material made up of micro-sized tungsten carbide particles dispersed within a cobalt matrix. While WC alone offers impressive hardness and wear resistance, it can be somewhat brittle. The addition of cobalt strengthens the material by binding the WC particles together, creating a unique combination that delivers exceptional mechanical properties, superior hardness, and improved wear resistance. The powder is precisely engineered to ensure uniform nanoparticle distribution, enabling accurate control for a variety of applications.

Tungsten Carbide Cobalt Powder (WC-12Co) Specifications

|

Material

|

WC-12Co

|

|

Particle Size (μm)

|

5-30, 15-45, 45-105, or customized

|

|

Purity

|

99.9%

|

|

Morphology

|

nearly spherical/ spherical

|

Chemical Composition Comparison (%)

|

Formula

|

W

|

Co

|

Ni

|

Cr

|

Total C

|

Free C

|

Fe

|

O

|

|

WC-5Co

|

Bal.

|

4.83~5.2

|

0.025

|

0.01

|

5.5~6.5

|

0.01~0.03

|

0.18~0.22

|

0.09

|

|

WC-6Co

|

Bal.

|

5.83~6.2

|

0.01~0.02

|

0.01

|

5.5~6.5

|

0.01~0.03

|

0.18~0.22

|

0.09

|

|

WC-8Co

|

Bal.

|

7.8~8.3

|

0.01~0.02

|

0.01

|

5.5~6.5

|

0.01~0.03

|

0.18~0.22

|

0.09

|

|

WC-10Co

|

Bal.

|

9.6~10.4

|

0.01~0.02

|

0.01

|

5.5~6.5

|

0.01~0.03

|

0.18~0.22

|

0.09

|

|

WC-12Co

|

Bal.

|

11.8~12.3

|

0.01~0.02

|

0.01

|

5.5~6.5

|

0.01~0.03

|

0.18~0.22

|

0.09

|

|

WC-15Co

|

Bal.

|

14.8~15.3

|

0.01~0.02

|

0.01

|

5.5~6.5

|

0.01~0.03

|

0.18~0.22

|

0.09

|

|

WC-17Co

|

Bal.

|

16.8~17.3

|

0.01~0.02

|

0.01

|

5.5~6.5

|

0.01~0.03

|

0.18~0.22

|

0.09

|

Advantages of WC-12Co Powder

- Higher Toughness: The 12% cobalt content significantly enhances the overall toughness of the material, enabling it to perform better when subjected to impacts and vibrations.

- Fracture Resistance: The higher cobalt proportion helps inhibit crack propagation, extending the service life of tools and components.

Tungsten Carbide Cobalt Powder (WC-12Co) Applications

1. Cutting and machining tools: Tungsten Carbide Cobalt Powder is commonly used in the production of cutting and machining tools, such as inserts, drills, end mills, and saw blades. Its high hardness and wear resistance make it ideal for use in these applications, where the tools need to withstand high temperatures, abrasion, and impact.

2. Mining and drilling tools: Another significant application of Tungsten Carbide Cobalt Powder is in the manufacturing of mining and drilling tools. Its superior hardness and toughness make it suitable for use in rock drilling, mining, and oil and gas exploration, as it can withstand the harsh environments and high pressures encountered in these operations.

3. Wear parts and components: Tungsten Carbide Cobalt Powder is also utilized in the production of wear parts and components for various industries. It is commonly used in applications such as valve seats, sleeves, seals, bearings, and nozzles, where the materials need to have excellent wear resistance and long service life.

4. Aerospace and defense industry: Tungsten Carbide Cobalt Powder finds applications in the aerospace and defense industries due to its high strength, hardness, resistance to thermal shock, and ability to withstand extreme conditions. It is used in applications such as turbine blades, armor-piercing projectiles, and parts for rocket engines.

5. Metalworking industry: Tungsten Carbide Cobalt Powder is frequently used in the metalworking industry for various purposes. It can be applied as a coating material to enhance the wear resistance and hardness of cutting tools, molds, and dies. Additionally, it is used as an additive in metal alloys to improve their performance and mechanical properties.

6. Medical and dental instruments: Tungsten Carbide Cobalt Powder is used in the manufacturing of medical and dental instruments, including surgical instruments, dental burs, and bone drills. Its high strength, corrosion resistance, and biocompatibility make it a suitable material for these applications.

7. Electronics and semiconductor industry: Tungsten Carbide Cobalt Powder is used in the electronics and semiconductor industry for various purposes. It can be employed as a coating material for cutting tools and wear-resistant components used in the manufacturing of electronic devices and circuit boards.

Tungsten Carbide Cobalt Powder (WC-12Co) Packaging

Our Tungsten Carbide Cobalt Powder (WC-12Co) is carefully handled during storage and transportation to preserve the quality of our product in its original condition.