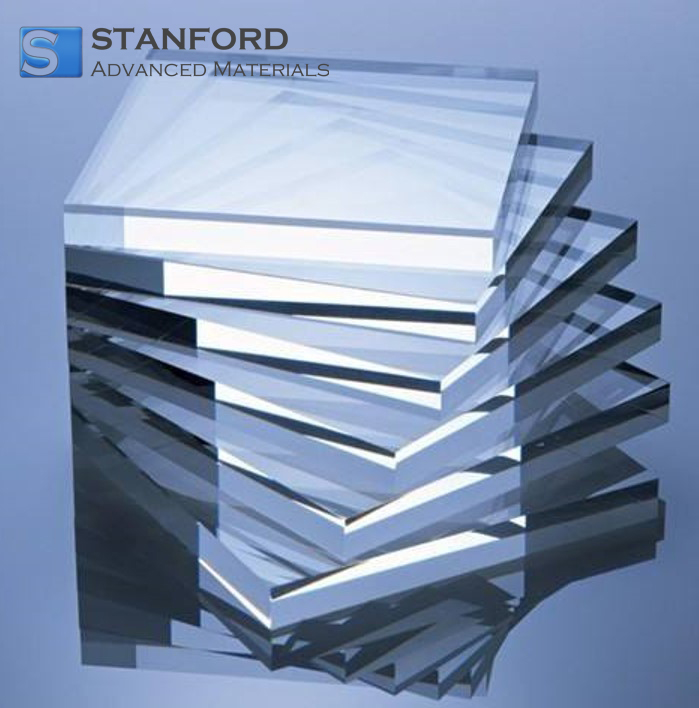

Transparent Spinel Customized Part Descriptions:

Transparent spinel (Magnesium aluminum transparent ceramics) has many applications in optics, electronics and structure.

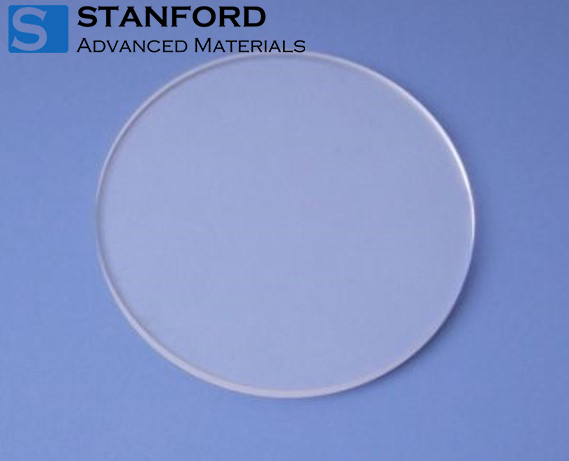

Transparent spinel can be used to prepare visible to mid infrared windows and lenses. The theoretical transmittance of 3~5μm is close to 87%, which is close to ALON and sapphire, and the cutoff wavelength is slightly longer than both, especially in the mid-infrared imaging system performance.

The properties of transparent ceramic spinel and alumina are similar. It’s suitable for various circuit components such as thick film circuit, thin film circuit, integrated circuit carrier and chip packaging and other high-performance substrate materials.

Transparent Spinel Customized Part Specifications:

|

Item

|

Unit

|

Typical Values

|

|

Molecular Formula

|

-

|

MgAl2O4

|

|

Crystal System

|

-

|

Cubic

|

|

Density

|

g/cm3

|

3.57-3.58

|

|

Physical Properties

|

|

Mohs Hardness

|

-

|

8.5

|

|

Vickers Hardness

|

N/mm2

|

>1.26 x 104

|

|

Modulus of Elasticity

|

Gpa

|

275

|

|

Flexural Strength

|

MPa

|

140-200

|

|

Compressive Strength

|

MPa

|

>500

|

|

DC Breakdown Strength

|

Kv/mm

|

34.5

|

|

Refractive Index

|

|

486.1nm

|

1.72433

|

2.2um

|

1.6848

|

|

546.1nm

|

1.71976

|

3.0um

|

1.6678

|

|

589.3nm

|

1.71611

|

4.0um

|

1.6387

|

|

The Thermodynamic Property

|

|

Melting Point

|

ºC

|

2135

|

|

Thermal Conductivity at 20℃

|

W/m•k

|

17.0

|

|

Thermal Conductivity at 100℃

|

W/m•k

|

16.4

|

|

Thermal Conductivity at 200℃

|

W/m•k

|

15.7

|

|

Thermal Conductivity at 300℃

|

W/m•k

|

14.9

|

|

Thermal Expansion Coefficient 20-300℃

|

10-6/℃

|

6.72

|

|

Thermal Expansion Coefficient 20-400℃

|

10-6/℃

|

7.07

|

|

Thermal Expansion Coefficient 20-500℃

|

10-6/℃

|

7.33

|

|

Electrical Property

|

|

Dielectric Strength

|

MV/m

|

>20

|

|

Dielectric Constant at 20℃

|

MHz

|

8.2

|

|

Dielectric Loss at 20℃

|

MHz

|

1.4x10-4

|

|

Volume Resistivity at 100℃

|

Ω•cm

|

1.2x1016

|

|

Volume Resistivity at 300℃

|

Ω•cm

|

6.3x1014

|

|

Volume Resistivity at 500℃

|

Ω•cm

|

9.4x1012

|

Transparent Spinel Customized Part Features:

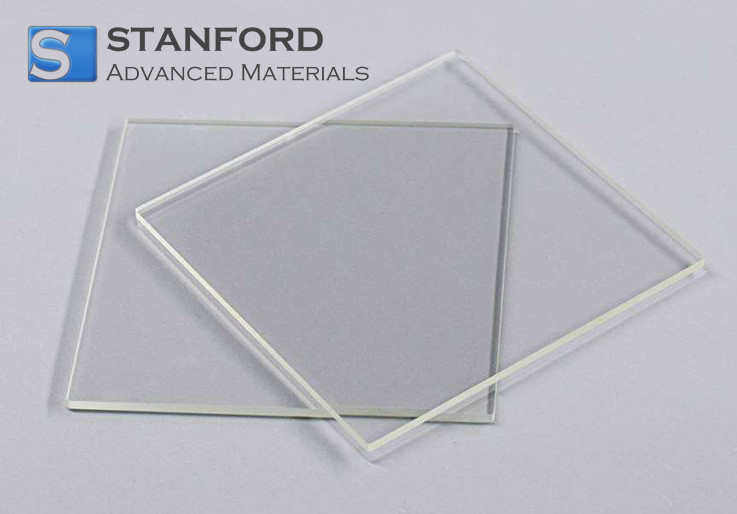

Transparent Spinel has the following advantages:

-no scratches under harsh conditions;

-the thickness can be reduced by more than 60% under the same protection requirements, and the weight can be effectively reduced;

-in the case of the same thickness, the protection ability can be improved.

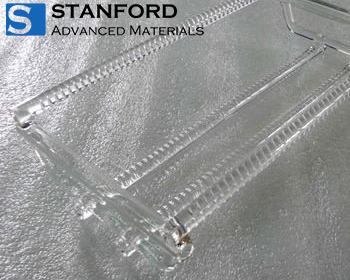

Therefore, it can be used in various high temperature, high pressure and corrosive environment of equipment observation window, gas detector window, high temperature boiler water level gauge, high temperature and high pressure equipment observation window, commercial bar code scanner window, downhole detection sensors, low voltage and high frequency capacitors, all kinds of goggles, etc.

Transparent Spinel Customized Part Applications:

- Various transparent seat, high temperature and corrosion resistant liquid pipe nozzles;

-High pressure gas discharge lamp shell.

Transparent Spinel Customized Part Packaging:

SAM’s Transparent Spinel Customized Part is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Transparent Spinel Customized Part FAQs

Q1. What is a Transparent Spinel Customized Part?

A transparent spinel customized part is a component made from magnesium aluminate spinel (MgAl₂O₄) that is tailored to specific shapes, sizes, and specifications required for unique applications. Spinel is prized for its exceptional optical clarity, hardness, and durability.

Q2: What precautions should be taken when using Transparent Spinel Customized Parts?

Handling: Handle with care to avoid mechanical damage. Use gloves to prevent contamination.

Cleaning: Avoid abrasive cleaners and materials that could scratch the surface.

Installation: Ensure proper mounting and support to prevent stress and potential cracking. Q3: Can Transparent Spinel Customized Parts be coated or treated for specific applications?

Yes, transparent spinel customized parts can be coated or treated with various optical coatings to enhance performance for specific applications. Anti-reflective coatings, hard coatings, and other specialized treatments can be applied to improve optical performance and durability.