Stainless Steel Honeycomb Description

Stainless Steel Honeycomb is a versatile material that combines the inherent benefits of stainless steel with the lightweight and strong honeycomb structure, making it ideal for various demanding applications. Its exceptional properties, including corrosion resistance, mechanical strength, and energy absorption, make it an excellent choice for aerospace, automotive, architecture, marine, and industrial applications, providing both performance and durability in challenging environments.

Stainless Steel Honeycomb Specification

|

Material

|

Stainless Steel

|

|

Shape

|

Rectangle, Round, or customized

|

|

Board Thickness

|

0.05-0.2 mm, or customized

|

|

Cell Size

|

0.8 to 30 mm

|

|

Finish

|

electroless nickel plating, tin plating, powder coating, paints

|

|

Dimensions

|

Customized

|

Stainless Steel Honeycomb Application

- Aerospace and Defense: Used in aircraft floors, walls, and panels, where high strength, lightweight properties, and corrosion resistance are critical.

- Automotive Industry: Applied in various components, including energy absorption parts, catalytic converter substrates, and vehicle panels, to reduce weight and enhance fuel efficiency.

- Architectural and Construction: Used in decorative panels, facades, and curtain walls to provide aesthetic appeal and structural support while minimizing weight.

- Marine Applications: Ideal for ship and boat components that require lightweight, corrosion-resistant materials.

- Industrial Uses: Employed in heat exchangers, furnace linings, and filtration systems where heat resistance and structural integrity are necessary.

Stainless Steel Honeycomb Packaging

Our Stainless Steel Honeycomb is carefully handled during storage and transportation to preserve the quality of our product in its original condition. Wood cages to avoid damage to your products during shipping.

FAQs

Q1: What is Stainless Steel Honeycomb?

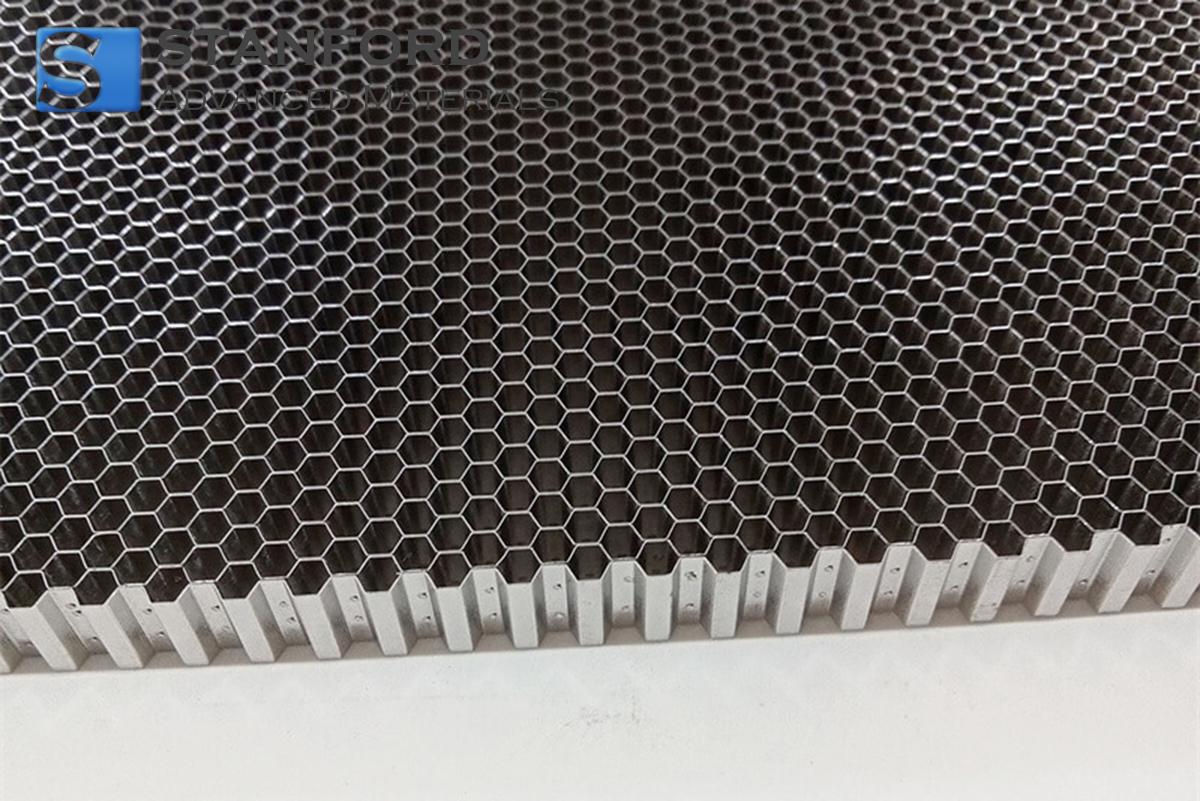

Stainless Steel Honeycomb is a lightweight, high-strength material with a honeycomb-like structure made from stainless steel sheets.

Q2: How is Stainless Steel Honeycomb manufactured?

Stainless Steel Honeycomb is typically manufactured using precision forming processes, including expansion, corrugation, or extrusion, followed by brazing or welding to create the honeycomb cells. It is then cut or shaped to the desired size and thickness for specific applications.

Q3: Can Stainless Steel Honeycomb be customized?

Yes, Stainless Steel Honeycomb can be customized to meet specific requirements, such as different cell sizes, densities, thicknesses, and shapes. It can also be provided in various finishes, coatings, and surface treatments to enhance its performance in specific environments.

Q4: Is Stainless Steel Honeycomb suitable for outdoor use?

Yes, Stainless Steel Honeycomb is highly suitable for outdoor use due to its excellent corrosion resistance and durability. It is often used in architectural applications, such as facades, roofing, and cladding, where it can withstand environmental exposure.

.jpg)