Tungsten Carbide Cobalt Chromium Powder (WC-10Co-4Cr) Description

Tungsten Carbide Cobalt Chromium Powder (WC-10Co-4Cr) is a high-performance composite alloy known for its exceptional hardness, wear resistance, and corrosion resistance. It is composed of tungsten carbide (WC) particles dispersed in a matrix of cobalt (Co) and chromium (Cr). It provides superior hardness and wear resistance, while the cobalt acts as a binder to hold the carbide particles together. The addition of chromium enhances the corrosion resistance of Tungsten Carbide Cobalt Chromium Powder for applications in harsh and corrosive environments.

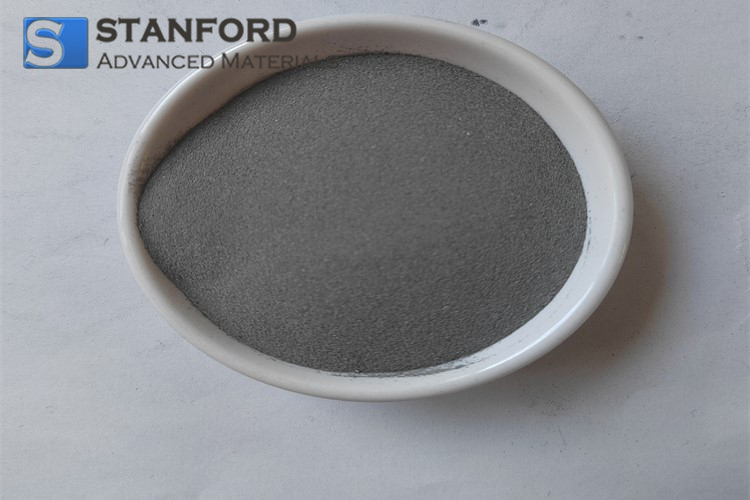

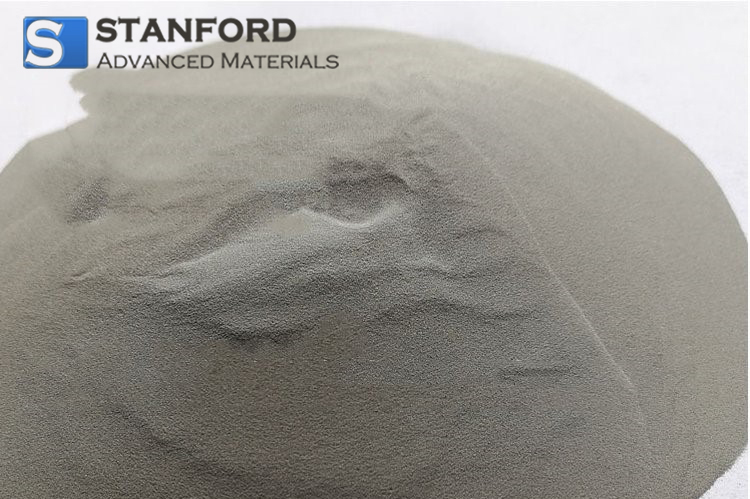

Tungsten Carbide Cobalt Chromium Powder (WC-10Co-4Cr) Specifications

|

Chemical Formula

|

WC-10Co-4Cr

|

|

Particle Size

|

1-60μm, or customized

|

|

Purity

|

99.9%

|

|

Morphology

|

nearly spherical

|

Chemical Composition

|

Formula

|

W

|

Co (%)

|

Cr (%)

|

Fe (%)

|

Free C (%)

|

Ni (%)

|

O (%)

|

|

WC-10Co-4Cr

|

Bal.

|

9.8~10.3

|

3.8~4.1

|

0.18~0.22

|

0.01~0.03

|

0.01~0.02

|

0.09

|

Tungsten Carbide Cobalt Chromium Powder (WC-10Co-4Cr) Applications

1. Cutting and machining tools: WC-CoCr Powder is widely used to manufacture cutting tools, such as drills, end mills, and inserts for milling, turning, and drilling operations. Its high hardness and wear resistance make it suitable for these applications.

2. Mining and drilling equipment: The hardness and toughness of WC-CoCr Powder make it ideal for the production of drill bits and other tools used in mining and drilling operations.

3. Wear-resistant coatings: WC-CoCr Powder can be used to create wear-resistant coatings on a variety of surfaces, including metal components and tooling. These coatings provide excellent resistance to abrasion, erosion, and corrosion, extending the lifespan of the coated parts.

4. Aerospace and defense applications: WC-CoCr Powder is extensively used in the aerospace and defense industries for manufacturing turbine blades, rocket nozzles, and other high-temperature components. Its high strength, wear resistance, and ability to withstand extreme conditions make it suitable for these applications.

5. Medical and dental tools: WC-CoCr Powder is used to produce a variety of medical and dental tools, including surgical instruments, orthopedic implants, and dental drill bits. Its biocompatibility, high hardness, and resistance to wear and corrosion make it well-suited for these applications.

6. Metal forming and shaping tools: WC-CoCr Powder is employed in the production of metal forming tools, such as dies, punches, and molds. These tools require high hardness and wear resistance to withstand the forces and wear associated with shaping and forming metal components.

7. Wear parts for industrial equipment: Components that experience high wear, such as seals, bearings, and nozzles, can be manufactured using WC-CoCr powder. These parts offer superior wear resistance and extended lifespan under demanding operating conditions.

Tungsten Carbide Cobalt Chromium Powder (WC-10Co-4Cr)

Safety Information

|

Signal Word

|

Warning

|

|

Hazard Statements

|

H334-H317-H228

|

|

Hazard Codes

|

F, Xn

|

|

Risk Codes

|

11-42/43

|

|

Safety Statements

|

22-23-24-37-45-60

|

|

RTECS Number

|

N/A

|

|

Transport Information

|

UN3178 4.1/PG III

|

|

WGK Germany

|

3

|

|

GHS Pictograms

|

|

Tungsten Carbide Cobalt Chromium Powder (WC-10Co-4Cr) Packaging

Our Tungsten Carbide Cobalt Chromium Powder (WC-10Co-4Cr) is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Evaporation Materials.jpg)