Spherical Haynes 230 Powder Description

Spherical Haynes 230 Powder is a vacuum induction melted, argon gas atomized, and spherical powder for additive manufacturing. Due to high resistance to oxidation and nitridation, Haynes 230 Powder has a good balance of high-temperature strength and oxidation. Haynes 230 Powder is suitable for gas turbines, as well as high-temperature applications in the chemical industry.

Spherical Haynes 230 Powder Specifications

Chemical Composition (%)

|

Ni

|

Cr

|

W

|

Mo

|

Mn

|

Si

|

Al

|

C

|

La

|

|

Bal.

|

22

|

14

|

2

|

0.6

|

0.5

|

0.35

|

0.07

|

0.01

|

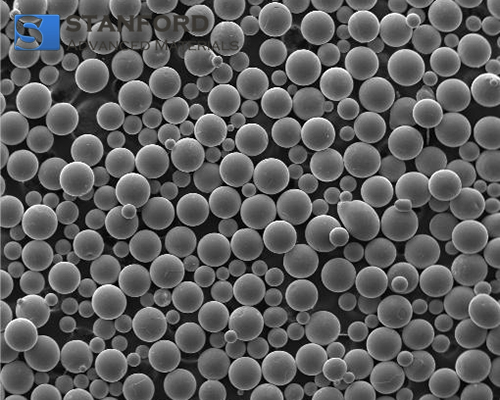

Physical Properties

|

Apparent Density (g/cm3)

|

4.2

|

|

Hall Flow (s/50g)

|

16

|

|

Particle Size (μm)

|

15-45, or customized

|

Spherical Haynes 230 Powder Applications

- Gas Turbine Components: Spherical Haynes 230 Powder is widely used in gas turbine components such as combustion chambers, turbine blades, and turbine vanes due to its excellent high-temperature strength, thermal stability, and corrosion resistance.

- Petrochemical Industry: The powder finds application in the petrochemical industry for applications like reactor vessels, heat exchangers, and high-temperature piping systems due to its exceptional resistance to corrosive environments and oxidation.

- Heat Treatment Furnaces: Haynes 230 Powder is employed in the construction of heat treatment furnaces and other high-temperature equipment where it exhibits superior creep resistance, thermal stability, and resistance to thermal fatigue.

- Aerospace Industry: The powder is suitable for aerospace applications, including jet engine components, exhaust systems, and aircraft structural parts, where it provides excellent strength and durability under high-temperature conditions.

- Power Generation: Spherical Haynes 230 Powder is utilized in power generation systems, such as gas turbines and steam turbines, where it offers exceptional resistance to high-temperature oxidation and thermal fatigue.

Spherical Haynes 230 Powder Packaging

Our Spherical Haynes 230 Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Powder.jpg)