DP5600 Spherical Cu-based Powder CuZrAlCo

| Catalog No. | DP5600 |

| Content | CuZrAlCo |

| Shape | Spherical Powder |

| Particle Size | 45μm |

Spherical Cu-based Powder CuZrAlCo is a high-performance alloy featuring copper (Cu) as the primary element, alloyed with zirconium (Zr), aluminum (Al), and cobalt (Co). Stanford Advanced Materials (SAM) specializes in providing this powder with exceptional purity and at highly competitive prices.

Related products: GRCop-42 Copper Alloy Spherical Powder, CuCrNb, Spherical Cu-based Powder CuTiZrNiSnSi, Spherical Cu-based Powder CuTiZrNi

Spherical Cu-based Powder CuZrAlCo Description

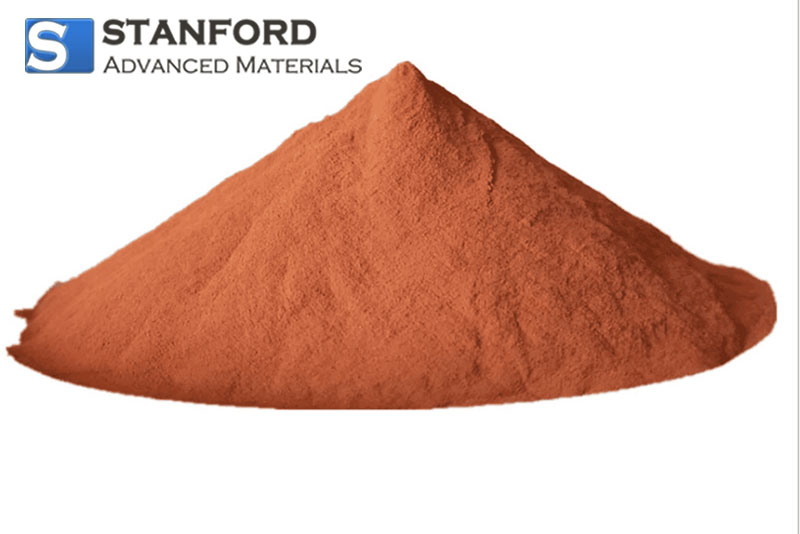

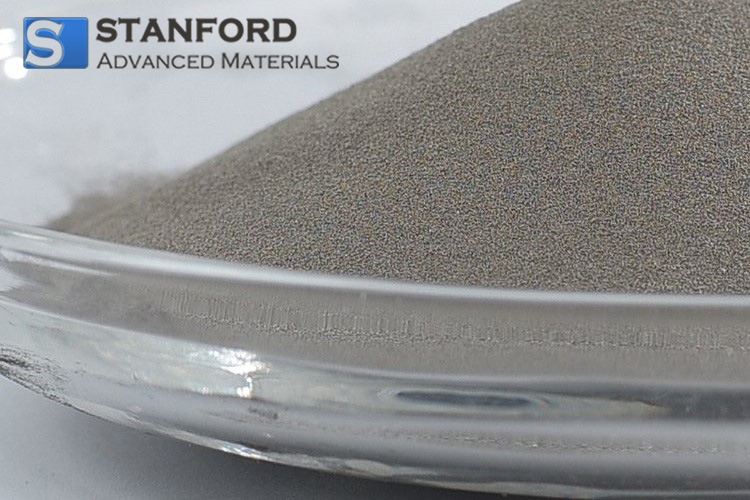

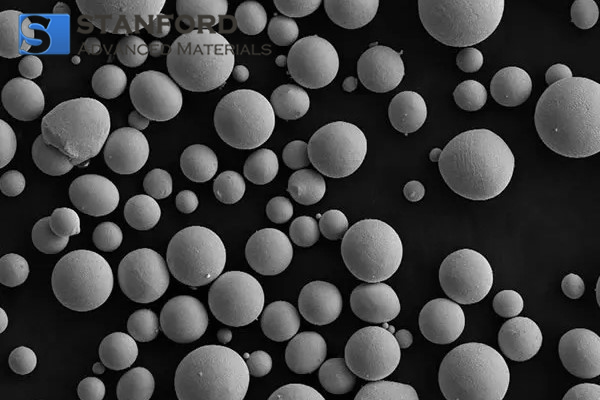

Spherical Cu-based Powder CuZrAlCo is a specialized alloy composed of copper (Cu) as the primary element, with additions of zirconium (Zr), aluminum (Al), and cobalt (Co). This alloy is engineered to leverage the excellent electrical and thermal conductivity of copper, while significantly enhancing its strength, hardness, wear resistance, and thermal stability through the strategic incorporation of Zr, Al, and Co. The powder's spherical morphology is particularly advantageous for applications requiring high flowability and density, such as additive manufacturing (3D printing), powder metallurgy, and as a feedstock for thermal spray coatings.

Spherical Cu-based Powder CuZrAlCo Specifications

|

MGs Composition |

Cu46Zr47Al6Co1 |

|

Powder size (μm) |

45, or customized |

|

Technique |

SLM |

|

Shape |

Spherical Powder |

Spherical Cu-based Powder CuZrAlCo Applications

- Electrical Components: Such as connectors and switches that benefit from copper’s conductivity alongside the enhanced mechanical properties for increased durability.

- Heat Sinks and Thermal Management: Where the material's thermal conductivity and improved mechanical strength are crucial for dissipating heat in electronic devices.

- Aerospace and Automotive Components: For parts that require a combination of strength, thermal stability, and conductivity, including sensors, actuators, and electrical connectors.

- Additive Manufacturing: The spherical powder facilitates the production of complex, precise parts that utilize the alloy’s unique combination of electrical, thermal, and mechanical properties.

- Bearings and Gears: Where the improved wear resistance and strength extend the life of components under high stress or in demanding environmental conditions.

- Corrosion-Resistant Coatings: Providing enhanced protection for metal surfaces in industrial, marine, and other corrosive environments.

Spherical Cu-based Powder CuZrAlCo Packaging

Our Spherical Cu-based Powder CuZrAlCo is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

FAQs

Q1: What are the main applications of Spherical Cu-based Powder CuZrAlCo?

Spherical Cu-based Powder CuZrAlCo is commonly used in advanced manufacturing processes like additive manufacturing (3D printing), thermal spray coatings, and powder metallurgy. They are ideal for applications requiring high strength, corrosion resistance, and excellent thermal conductivity.

Q2: What is the typical particle size distribution for Spherical Cu-based Powder CuZrAlCo?

The particle size distribution varies depending on the specific application and manufacturer specifications but typically ranges between 10 µm and 100 µm for 3D printing and coating purposes.

Q3: What production methods are used for Spherical Cu-based Powder CuZrAlCo?

It is typically produced using gas atomization, ensuring spherical morphology, low oxygen content, and uniform particle size distribution.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!