Spherical Cobalt Alloy Powder - CoCrMoW Description

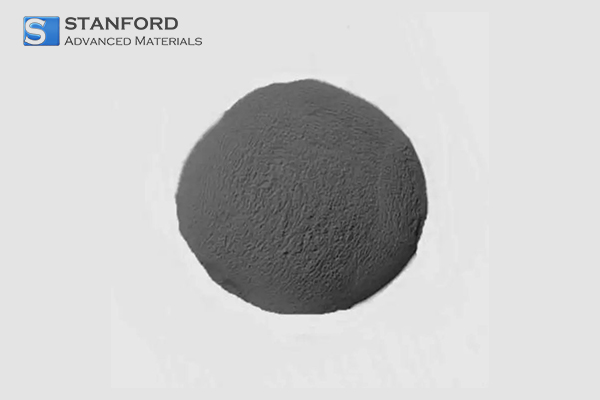

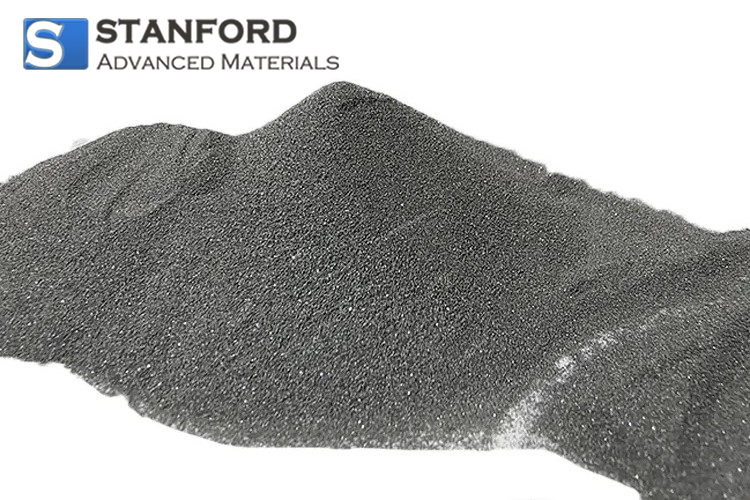

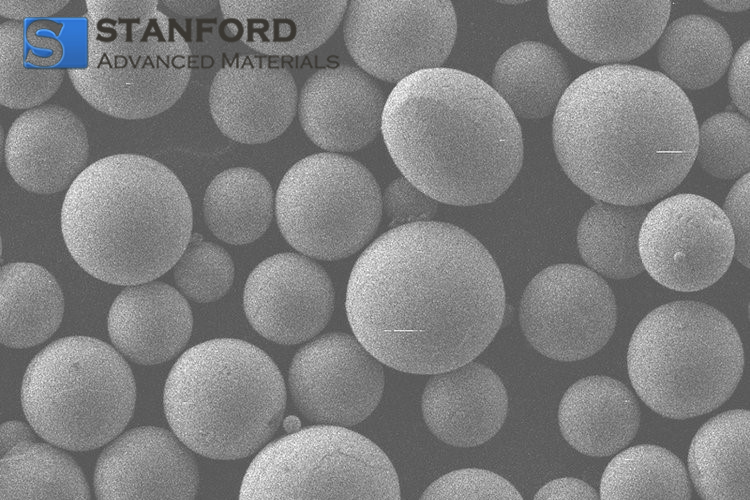

Spherical Cobalt Alloy Powder- CoCrMoW is a cobalt-based alloy with a small amount of Cr, Mo, W, and other elements. Its excellent biocompatibility and corrosion resistance give CoCrMoW an irreplaceable role, especially in medical implants and dental dentures. Spherical Cobalt Alloy Powder- CoCrMoW has good sphericity, low oxygen content, and uniform particle size distribution characteristics and can be used in the 3D printing area.

Spherical Cobalt Alloy Powder - CoCrMoW Specifications

|

Chemical Formula

|

CoCrMoW

|

|

Particle Size

|

15-53μm, 45-105μm or customized

|

|

Apparent Density (g/cm3)

|

4.2

|

|

Flowability

|

≤20s/50g

|

|

Purity

|

99.9%

|

Spherical CoCrMoW Chemical Composition (%)

|

Co

|

Bal.

|

|

Cr

|

22.7~26.7

|

|

Mo

|

4 ~5.6

|

|

W

|

4.40~6.0

|

|

Si

|

0.80~1.20

|

|

Fe

|

≤0.50

|

|

O

|

≤0.01

|

Spherical Cobalt Alloy Powder - CoCrMoW Applications

- Aerospace: CoCrMoW powder is suitable for aerospace applications, including turbine blades, combustion chambers, and structural components, where high strength, excellent corrosion resistance, and heat resistance are required.

- Medical and Dental: This powder can be used in producing medical and dental implants, such as hip and knee prostheses, dental crowns, and surgical instruments, due to its biocompatibility and excellent mechanical properties.

- Oil and Gas: CoCrMoW alloy powder finds applications in the oil and gas industry, such as in drilling tools, valves, and pumps, offering high wear resistance, good corrosion resistance, and high strength.

- Additive Manufacturing: The powder is suitable for additive manufacturing techniques, including powder bed fusion (PBF) and selective laser melting (SLM), to produce complex and customized parts with superior mechanical properties.

Spherical Cobalt Alloy Powder - CoCrMoW Packaging

Our Spherical Cobalt Alloy Powder- CoCrMoW is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Spherical Cobalt Alloy Powder - CoCrMoW FAQs

Q1: What are the primary applications?

Used in additive manufacturing, coatings, high-performance magnets, medical implants, and aerospace components.

Q2: How is Spherical Cobalt Alloy Powder produced?

Typically produced through gas atomization or plasma atomization, ensuring spherical particle shape and uniform size distribution.

Q3: What are the benefits of the spherical shape?

Enhances flowability, packing density, and uniformity in additive manufacturing and powder metallurgy.