MPP Molypermalloy (Gas-atomized) Powder Description

MPP Molypermalloy (Gas-atomized) Powder is a toroidal magnetic material comprised of the powder of multiple alloys. It is distributed with air gaps to help condense its magnetic field to minimize core losses. MPP Molypermalloy (Gas-atomized) Powder core maintains the lowest core losses out of all the magnetic powdered cores used. Its permeability can range from 14 to 550. The toroidal powder is used in the development of a subgroup of microelectronics known as inductors, transformers, and electronic filters.

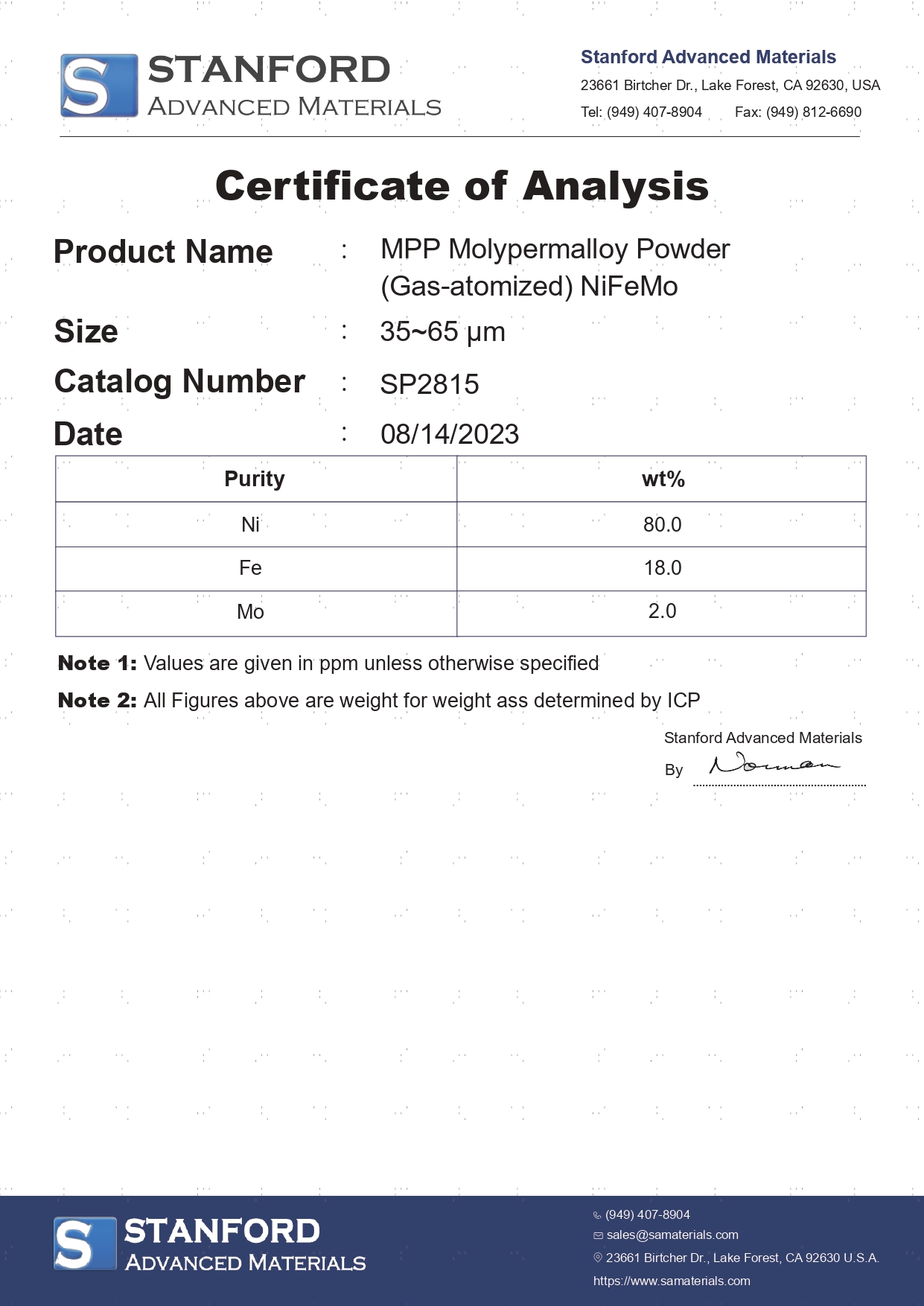

MPP Molypermalloy (Gas-atomized) Powder Specifications

|

Product Name

|

MPP Molypermalloy (Gas-atomized) Powder

|

|

Composition

|

80% Nickel, 18% Iron, and 2% Molybdenum

|

|

Process

|

Gas-atomized

|

|

Permeability

|

125~220

|

|

Fluidity(s/50g)

|

<20

|

|

A.D.(g/cm^3)

|

>4.8

|

|

O.C. (PPM)

|

<600

|

|

Particle size(μm)

|

35~65

|

MPP Molypermalloy (Gas-atomized) Powder Application

MPP Molypermalloy Powder was developed into cores by the Western Electric Company and the Bell Telephone Laboratory (formerly known as AT&T) in the early 1940s. It has made its largest impact on the power conversion field by permitting increased frequency, resulting in weight reduction and increased compactness in computer systems.

MPP Molypermalloy (Gas-atomized) Powder cores are primarily used in inductors that require a core to have a higher saturation point while maintaining other valuable magnetic properties. A standard MPP core saturates at around 0.75 Tesla. A ferrite core saturates at around 0.45 Tesla. Molypermalloy powder cores are commonly used in the making of flyback transformers, resonant circuits, quartz filters, loading coils, choke coils, pulse transformers, and other industrial and military circuits.

MPP Molypermalloy (Gas-atomized) Powder Features:

High Magnetic Permeability: MPP Molypermalloy Powder exhibits a high magnetic permeability, which makes it an ideal choice for applications where magnetic shielding and control are crucial.

Low Hysteresis Loss: This alloy possesses low hysteresis loss, which results in minimal energy dissipation and is essential for applications demanding high energy efficiency.

Uniform Composition: Gas-atomization ensures uniform composition and particle size distribution, contributing to consistent magnetic properties.

MPP Molypermalloy (Gas-atomized) Powder Benefits:

Exceptional Magnetic Shielding: The high magnetic permeability of MPP Molypermalloy Powder makes it highly effective in shielding sensitive electronic components from external magnetic fields.

Energy Efficiency: Its low hysteresis loss makes it suitable for use in transformers, inductors, and other magnetic devices, improving energy efficiency.

Precision and Consistency: The uniform composition and particle size distribution contribute to precise and consistent results in various manufacturing processes.

MPP Molypermalloy (Gas-atomized) Powder Packaging

Our MPP Molypermalloy (Gas-atomized) Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.